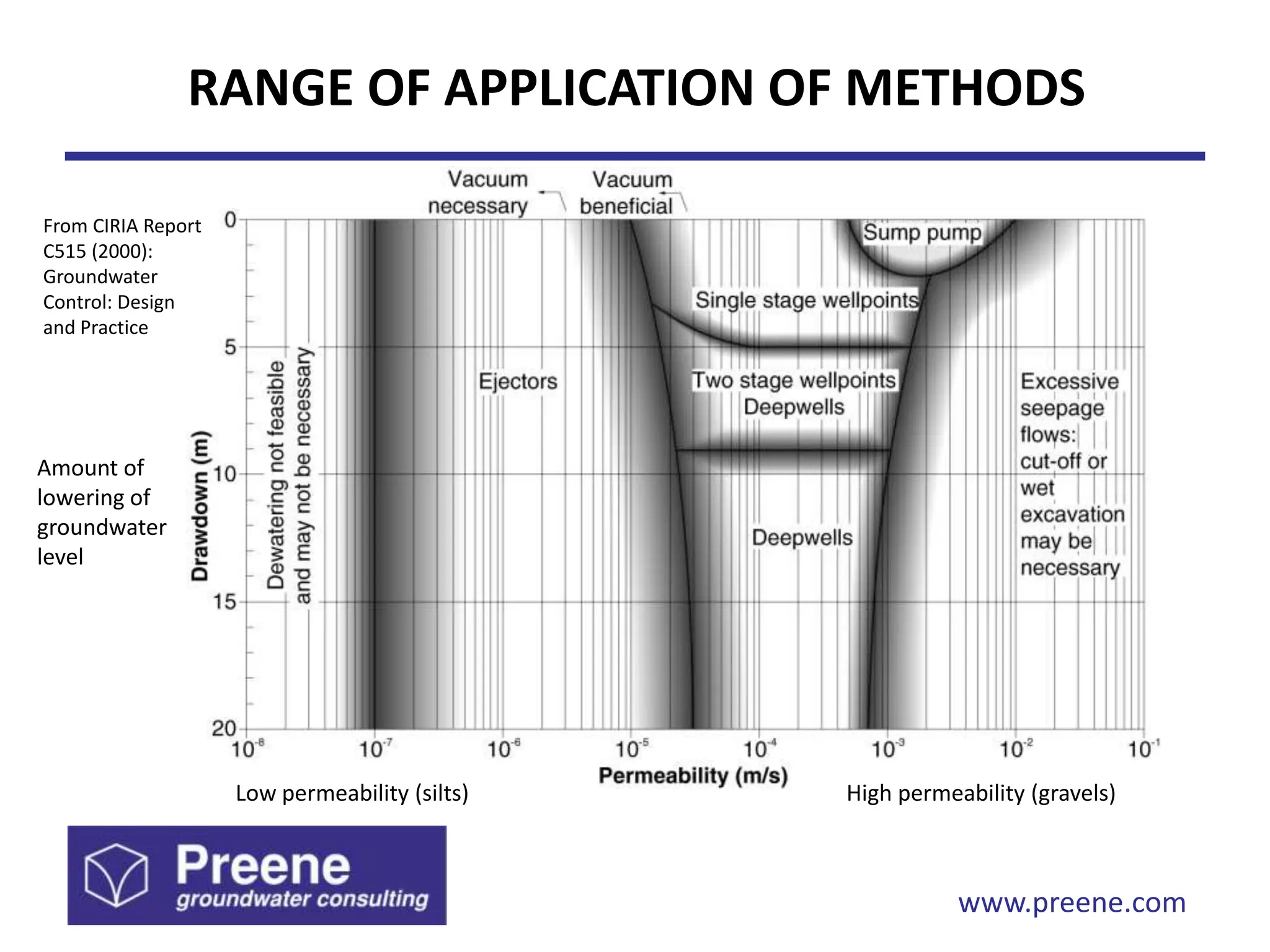

This document provides an overview of groundwater control for construction. It defines groundwater control as temporarily dealing with groundwater to allow excavations below the water table. The main approaches to groundwater control are exclusion, using physical barriers like cut-off walls, and pumping using well arrays. Good design requires understanding site conditions through investigation to develop an appropriate conceptual model and select analysis methods. Both empirical and analytical approaches are used, with numerical modeling for more complex sites. Observational methods also allow adapting designs based on monitoring.