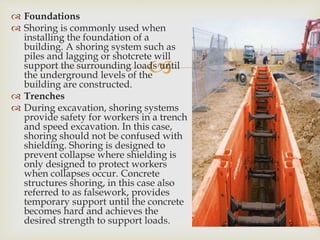

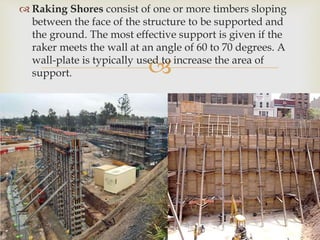

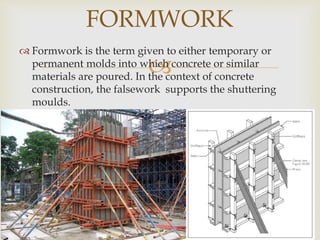

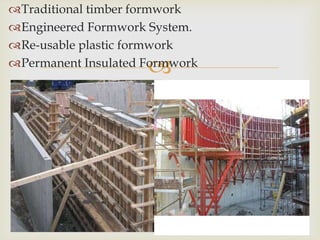

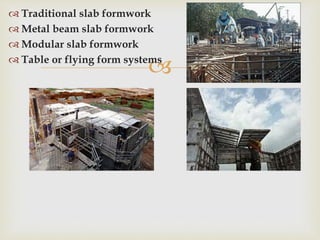

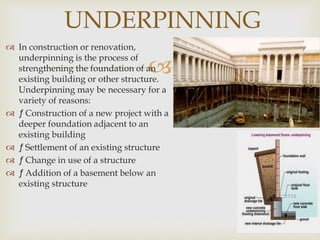

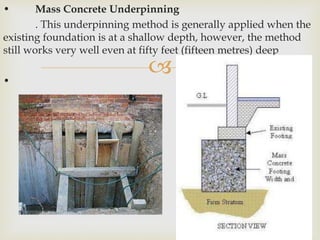

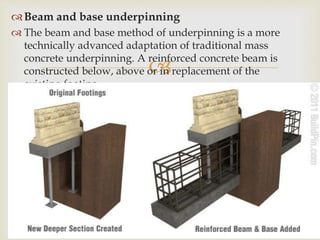

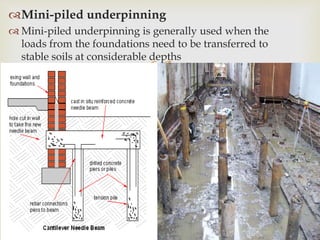

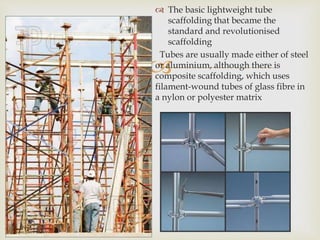

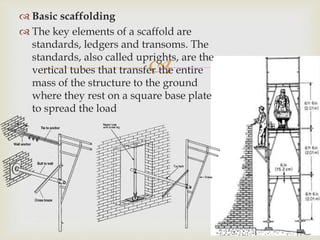

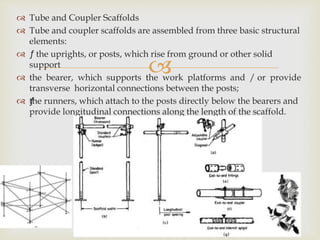

The document discusses various types of temporary structures used in construction including scaffolding, shoring, underpinning, and formwork. It provides details on common scaffolding systems made of metal tubes. It describes different shoring techniques like raking shores, hydraulic shoring, and soil nailing used to support trenches, foundations, and retaining walls. Formwork is discussed as temporary or permanent molds for pouring concrete. Methods of underpinning foundations include mass concrete, beams, and mini-piles.

![

Shoring is the process of supporting a building,

vessel, structure, or trench with shores (props) when

in danger of collapse or during repairs or alterations.

Shoring comes fromshore a timber or metal prop.[1]

Shoring may be vertical, angled, or horizontal.

SHORING](https://image.slidesharecdn.com/groupno9-150515061855-lva1-app6892/85/Group-no-9-7-320.jpg)