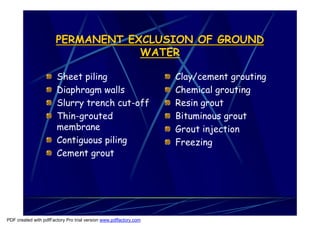

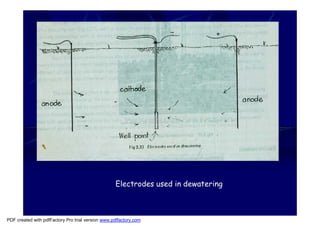

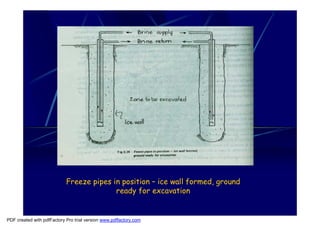

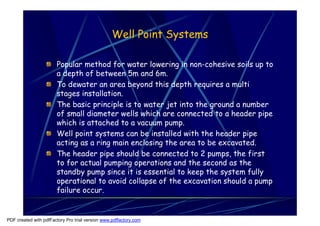

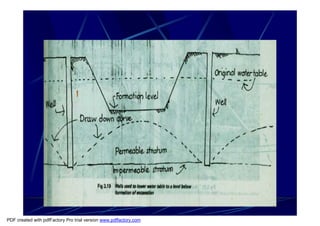

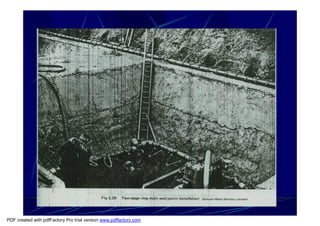

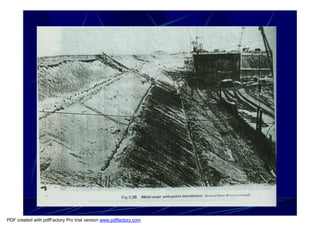

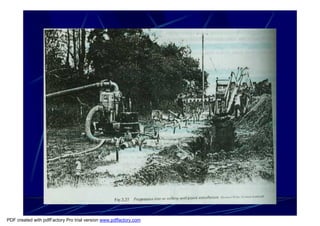

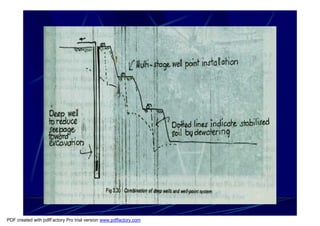

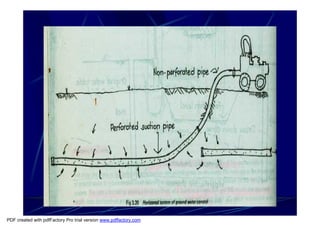

The document discusses various methods for controlling groundwater, which can be divided into permanent and temporary exclusion. Permanent exclusion methods like sheet piling, diaphragm walls, and grouting form barriers to block groundwater flow. Temporary methods like dewatering wells and deep boring lower the water table to allow for excavation work before groundwater levels return. The effectiveness of each method depends on the soil type and project needs.