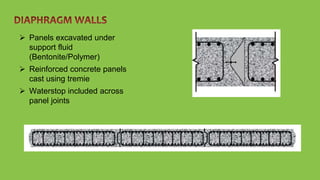

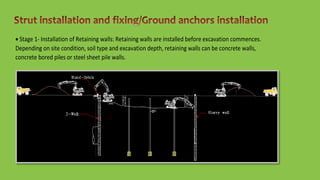

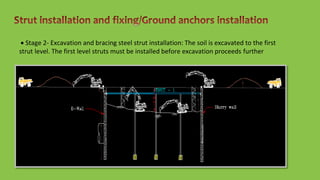

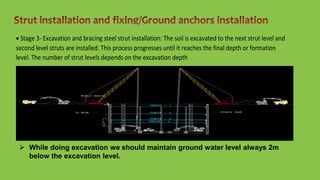

This document discusses deep excavation methods used for underground construction. Deep excavation is defined as deeper than 15 feet and requires retaining structures like walls, piles, or sheets. Common methods are bottom-up, top-down, and cut-and-cover. Retaining structures are installed, then the soil is excavated in levels while installing horizontal steel struts for bracing before further excavation. Dewatering using sumps, pumps, and wells is also required to control groundwater levels during excavation. Deep excavation is used to construct underground metro stations, tunnels, buildings, and dams.