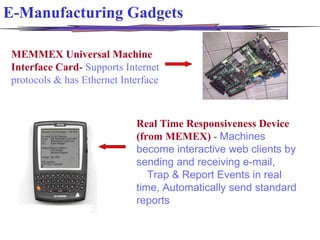

E-manufacturing involves fully integrating business processes and systems through technologies like e-procurement, supply chain management, customer relationship management, and enterprise resource planning. It connects the entire enterprise from the plant floor to customers using electronic and web-based technologies. This allows for faster and more flexible manufacturing that can quickly adapt to changing business needs and better collaborate with suppliers and customers.

![Enterprise Resource Planning (ERP) With ERP everyone in the enterprise relies on the same database & at the same information ERP integrates the information used by an organization's many different functions and departments into a unified computing system. [Contrasts use of isolated departmental databases to manage information, such as employee records, customer data, purchase orders, and inventory.]](https://image.slidesharecdn.com/e-manufacturing-100908090129-phpapp02/85/E-manufacturing-21-320.jpg)