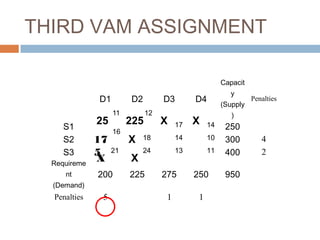

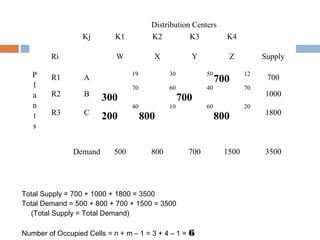

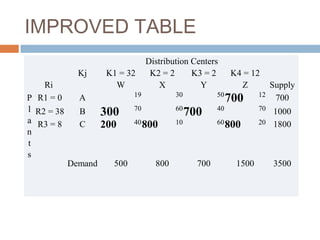

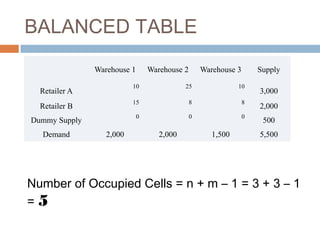

The document describes the Vogel's Approximation Method (VAM) and Modified Distribution Method (MODI) for solving transportation problems. VAM provides an initial feasible solution that is either optimal or near-optimal by iteratively assigning units based on opportunity costs. MODI tests the optimality of the initial solution by computing improvement indices for unused squares - if no negative indices exist, the initial solution is optimal. The methods are illustrated on examples involving determining the optimal shipping schedule from multiple sources to destinations to minimize total cost while meeting supply and demand constraints.