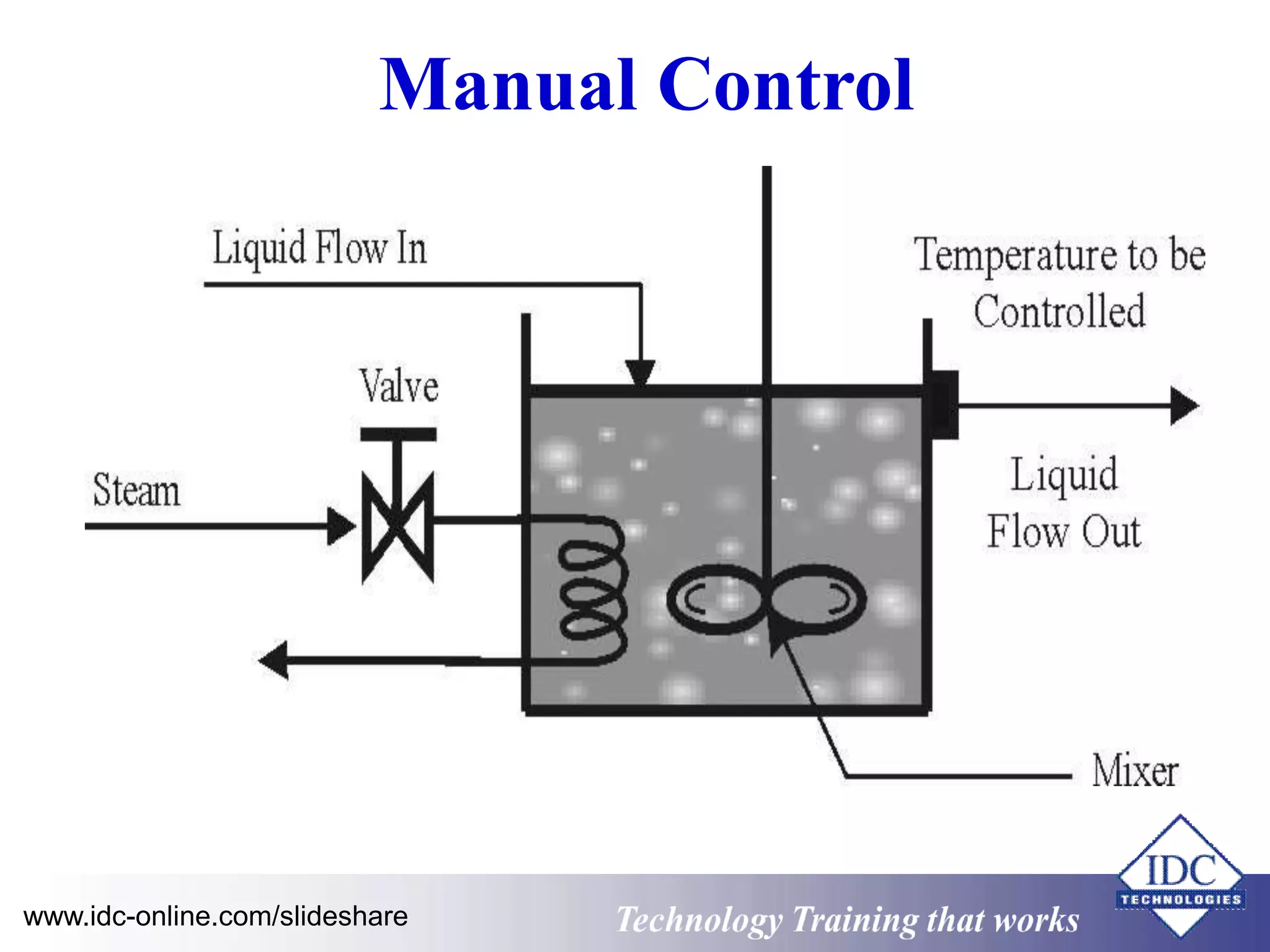

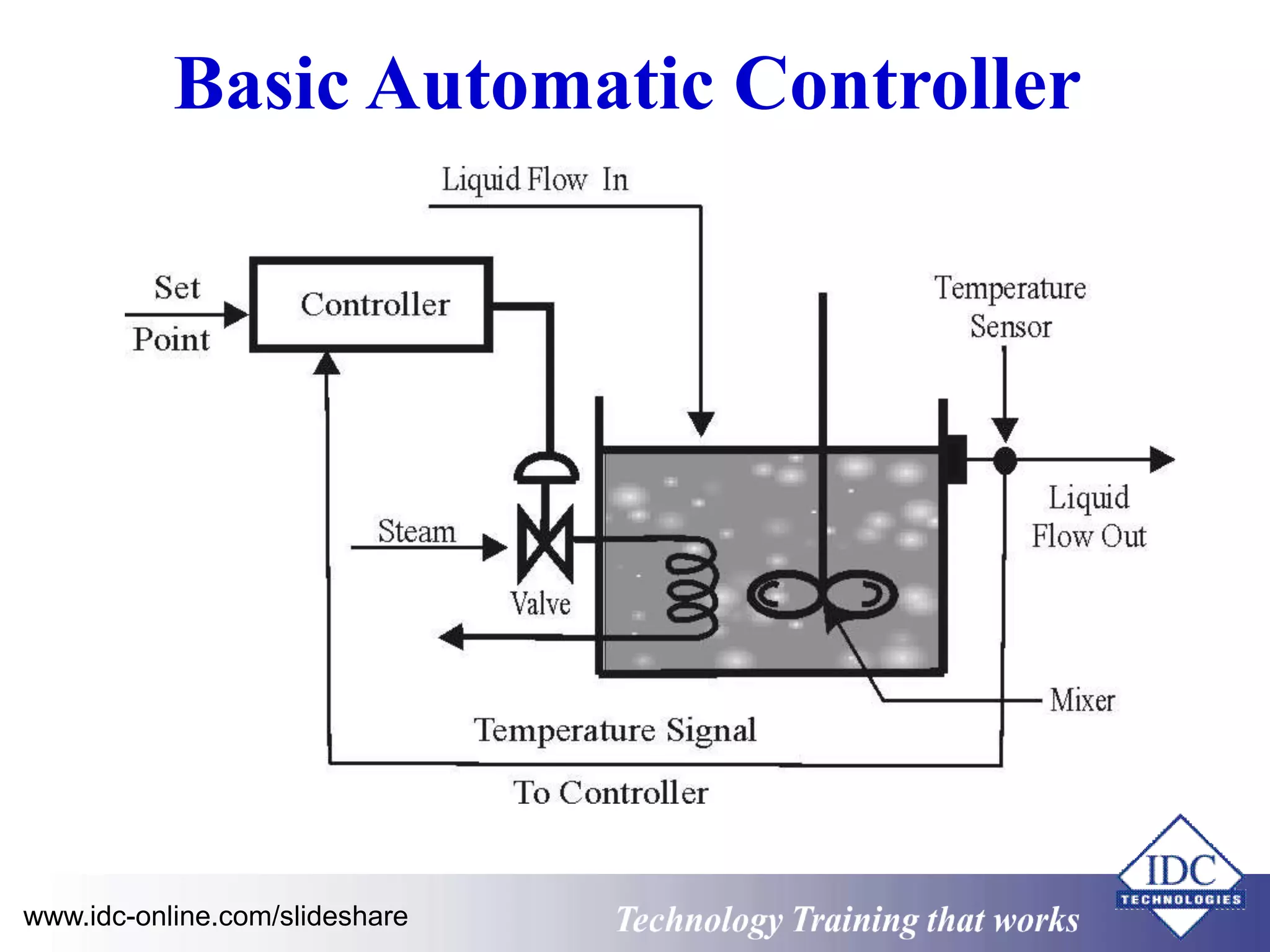

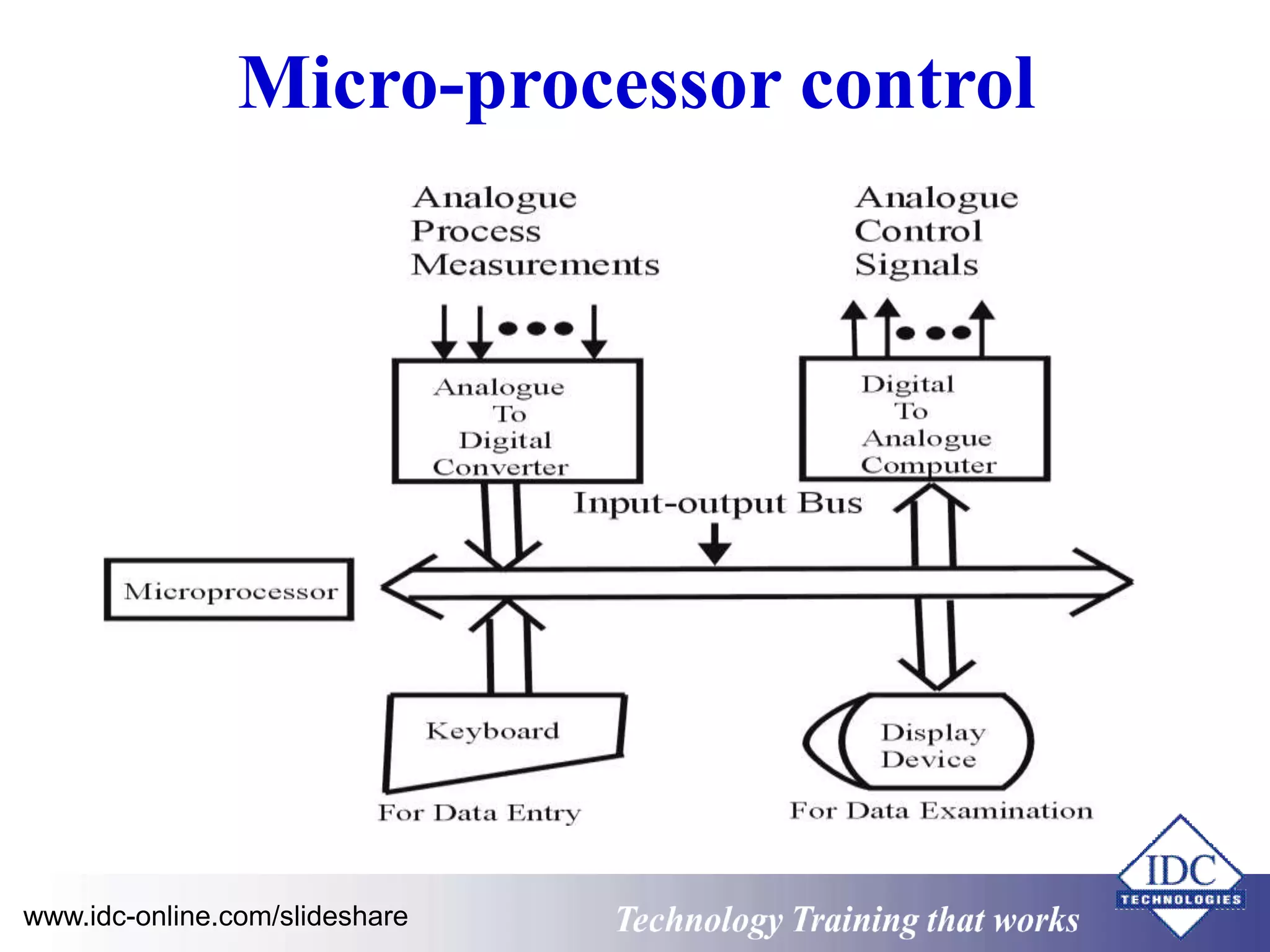

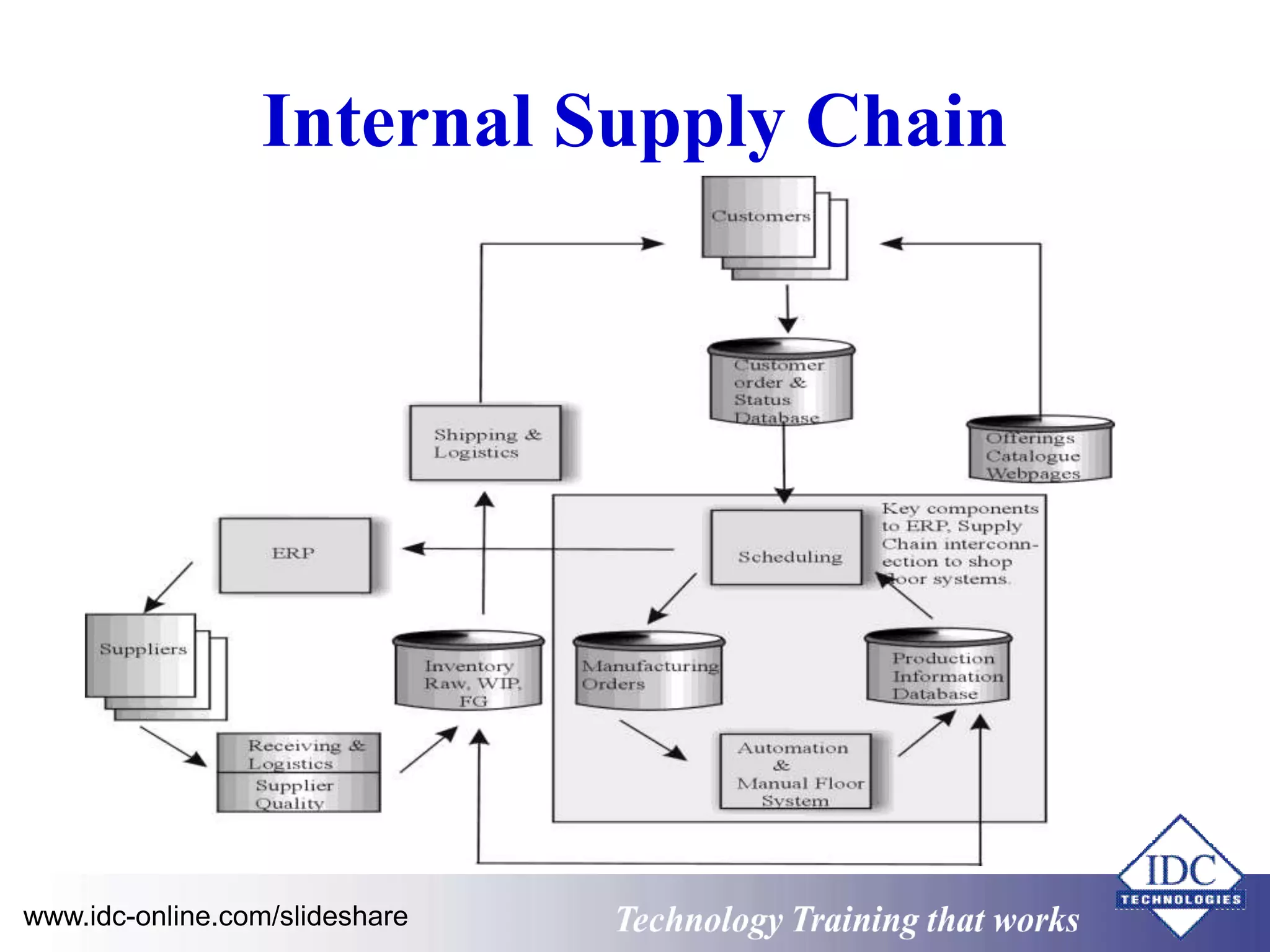

The document outlines the fundamentals of e-manufacturing, manufacturing execution systems (MES), and supply chain management (SCM), detailing the evolution of process control from manual methods to advanced systems. It highlights the benefits of these systems, including enhanced reliability, safety, and accuracy, while also addressing the complexities involved in SCM. Additionally, it emphasizes the roles of various measurement and control instruments in modern manufacturing processes.