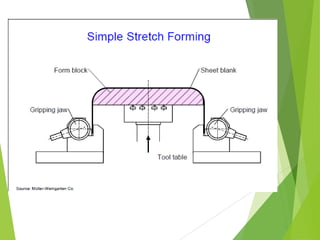

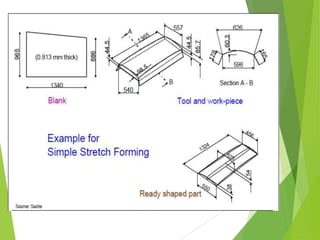

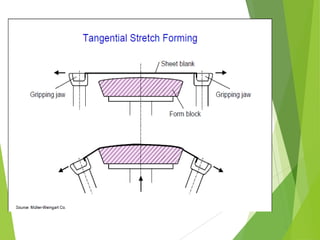

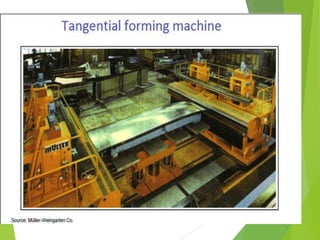

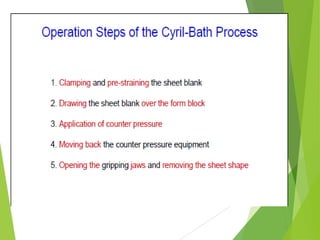

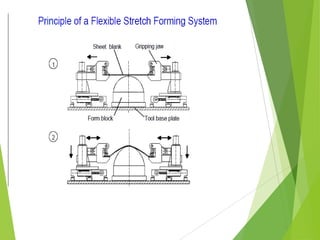

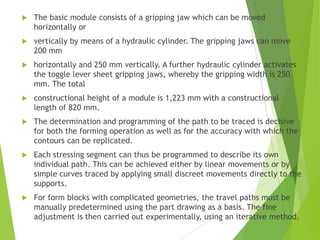

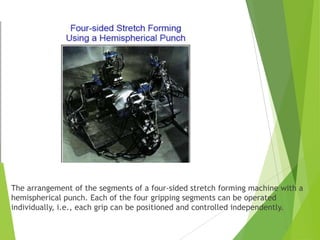

Stretch forming is a sheet metal forming process where a sheet blank is clamped at the edges and formed using a rigid punch. There are several types of stretch forming including simple, tangential, Cyril-Bath, and multi-sided stretch forming. Tangential stretch forming applies a tensile stress before forming for more uniform deformation. The Cyril-Bath process uses grips that move horizontally and vertically to form parts in a press. Multi-sided stretch forming clamps the blank on all sides for complex geometries. Stretch forming is used to produce large, flat parts with low tooling costs.