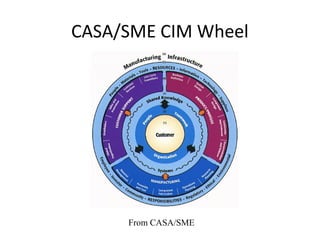

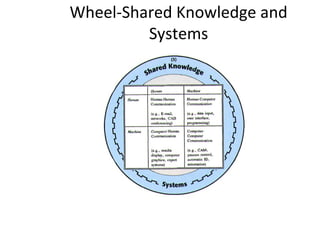

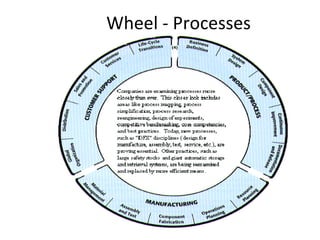

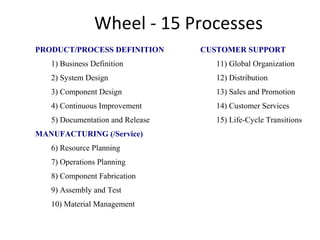

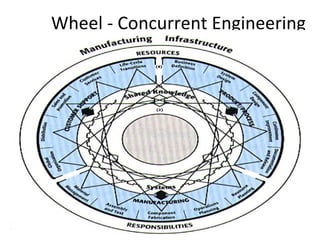

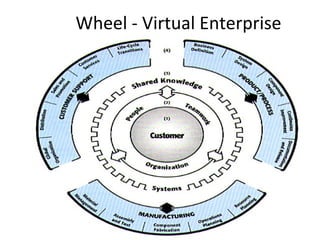

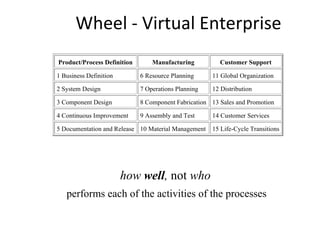

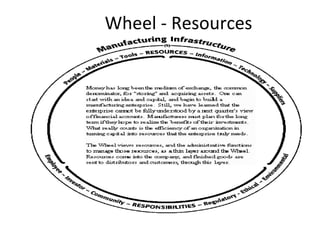

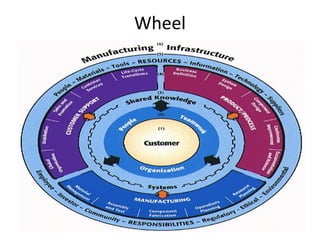

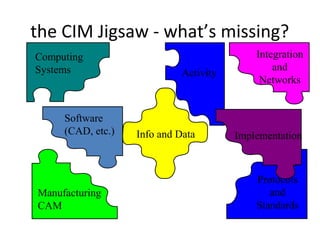

Computer Integrated Manufacturing (CIM) refers to the integration of business, engineering, manufacturing and management information that spans company functions from marketing to product distribution. The CASA/SME CIM Wheel provides an overview of CIM and identifies six key elements: the central role of the customer, people and teamwork, shared knowledge and systems, key processes, resources and responsibilities, and the manufacturing infrastructure. CIM aims to integrate these elements across the enterprise through computing systems, software, data integration and networks to achieve benefits like reduced costs and lead times through coordinated activities.