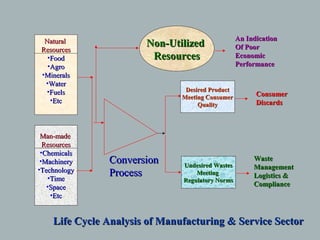

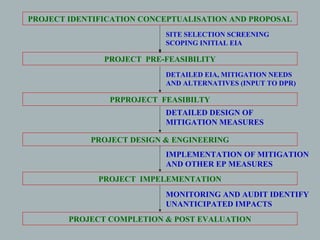

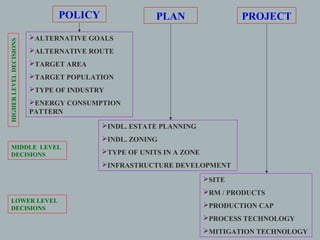

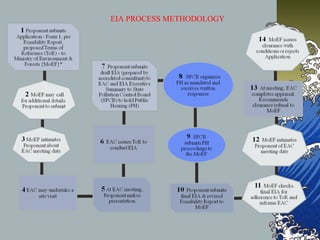

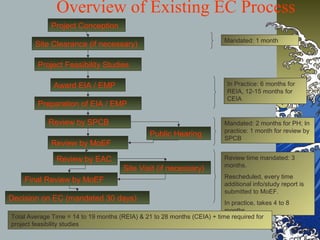

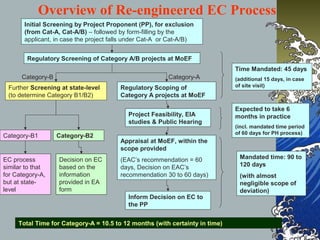

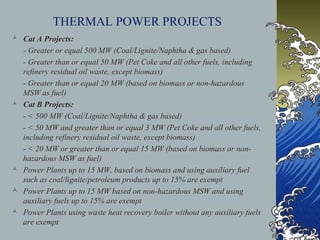

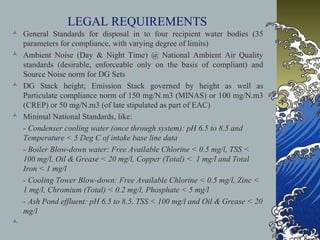

This document provides an overview of environmental impact assessment processes and requirements. It discusses the types of natural and man-made resources that are considered in EIAs, as well as the desired products, undesired wastes, and life cycle analysis involved. It also outlines the steps in the EIA process, requirements for EIA organizations, methodology, sector categorization including for thermal power projects, and some potential procedural violations.