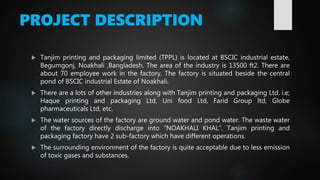

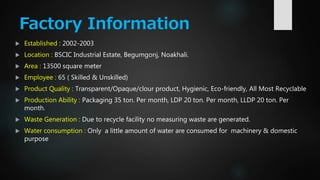

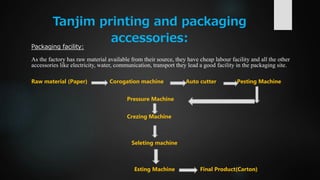

Tanjim printing and packaging limited (TPPL) commissioned an environmental impact assessment to evaluate its operations. The assessment identified some potential negative impacts, such as noise pollution and improper waste disposal, but also noted several beneficial impacts like job creation and recycling programs. The report recommends mitigation measures to address the negative impacts through compliance with health and safety standards, proper use of protective equipment, and emergency response planning. It concludes that if TPPL implements the suggested environmental management plan, the company can operate in an environmentally friendly manner.

![Objectives of EIA

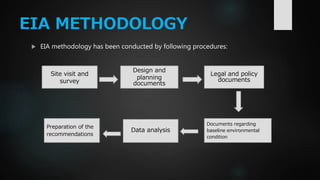

The objective of the study is to provide an examination and assessment of the principal environmental

impact of the industry. The overall objectives of the assessment report are-

To identify and describe elements of environment already affected or likely to be affected by the

and/or likely to cause adverse impacts to the proposed project, including natural and man-made

environment.

To identify and quantify emission sources and determine the significance of impacts on sensitive

and potential affected users

To identify and quantify any potential losses or damage to flora, fauna and natural habitats.

To determine based on knowledge whether the proposed investment may result in environmental

impacts;

Propose mitigation and monitoring measures in the form of applicable safeguard documentation to

address potential impacts;

Evaluate the existing institutional capacity of the company cadre to manage the recommendations

implementing the measures outlined in the Environment Management and Monitoring Plan [EMMP]

Provide recommendations to build capacity and strengthen environmental management and](https://image.slidesharecdn.com/eiareportof-170725075531/85/EIA-report-presentation-5-320.jpg)