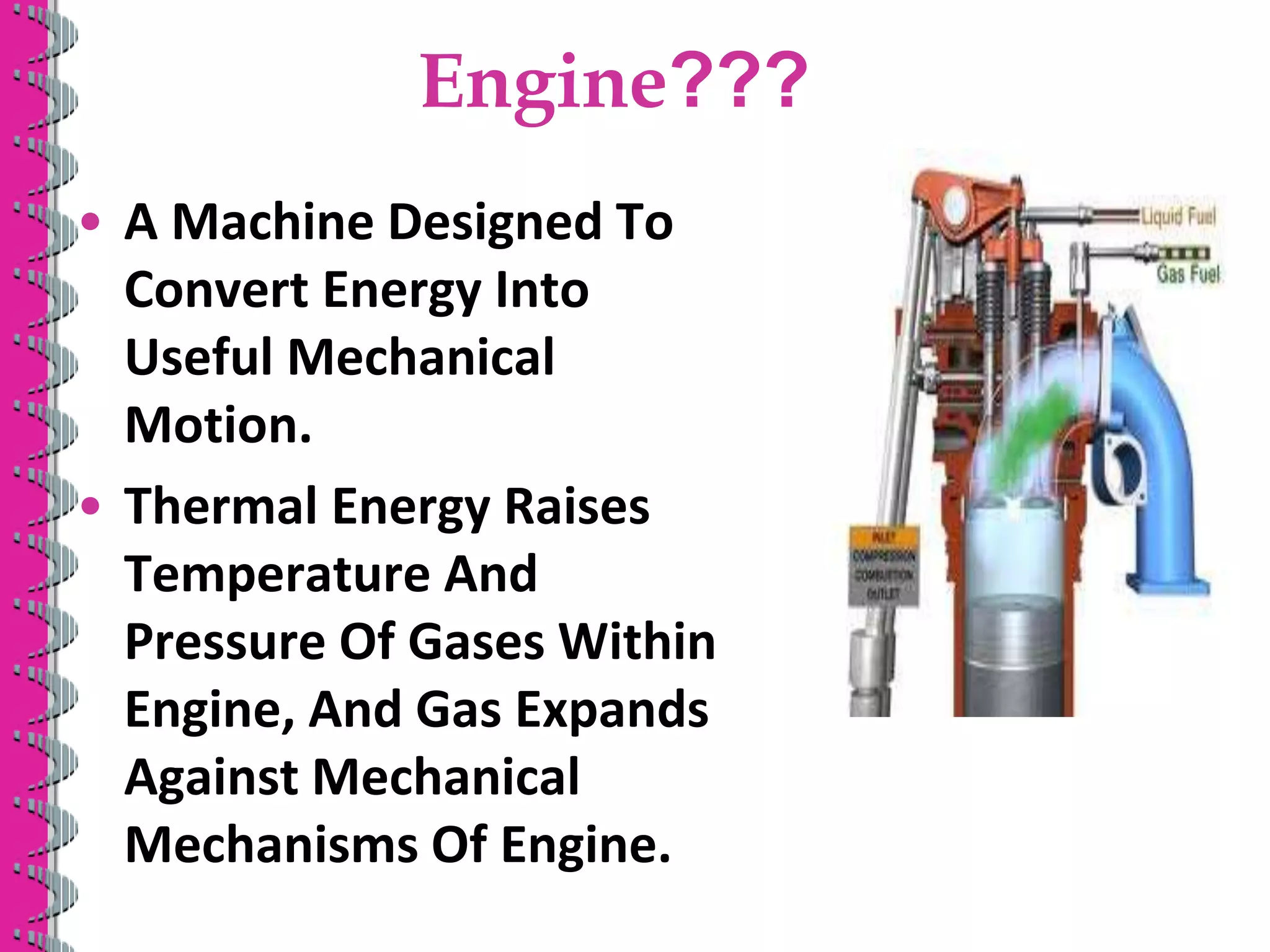

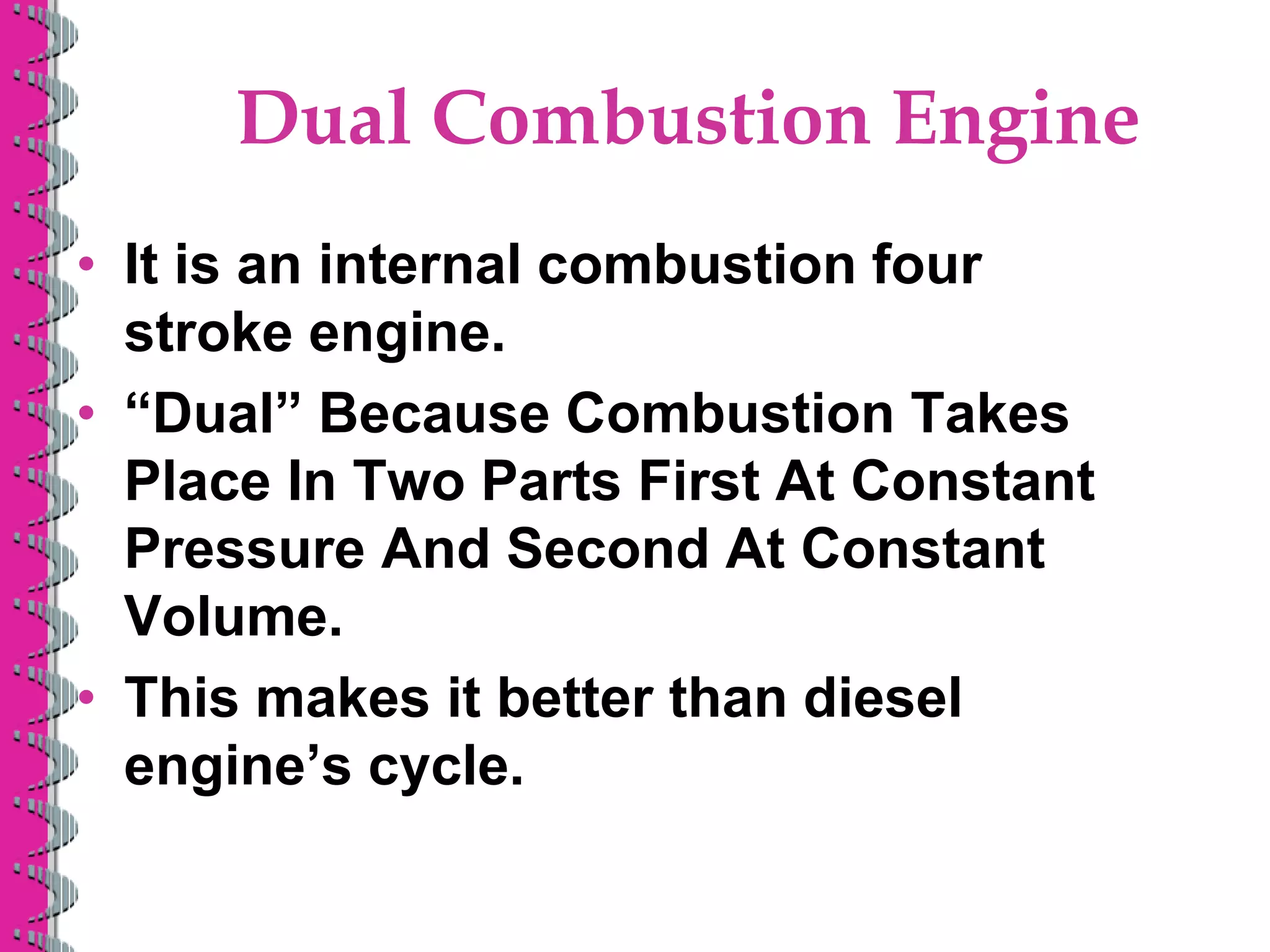

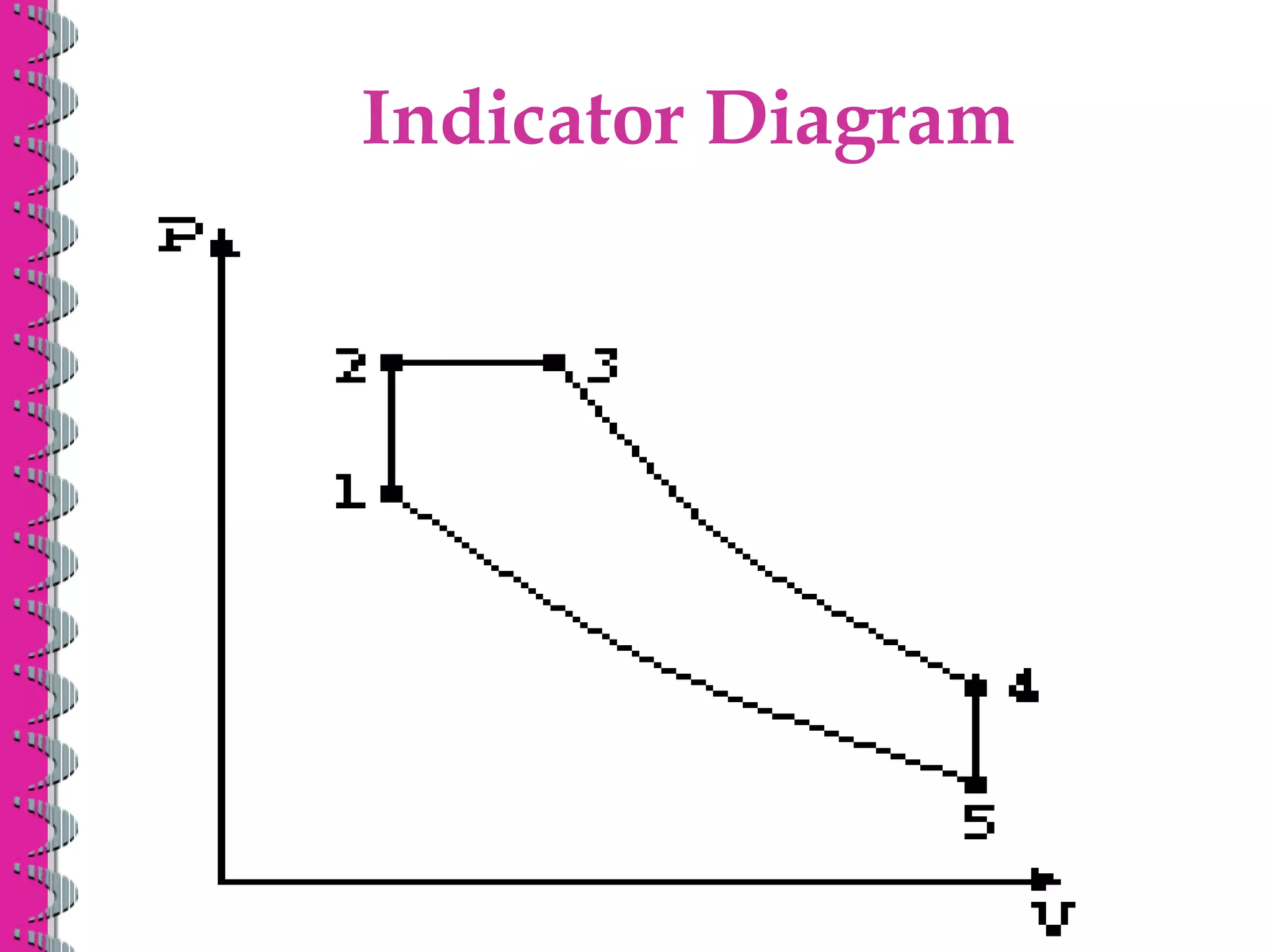

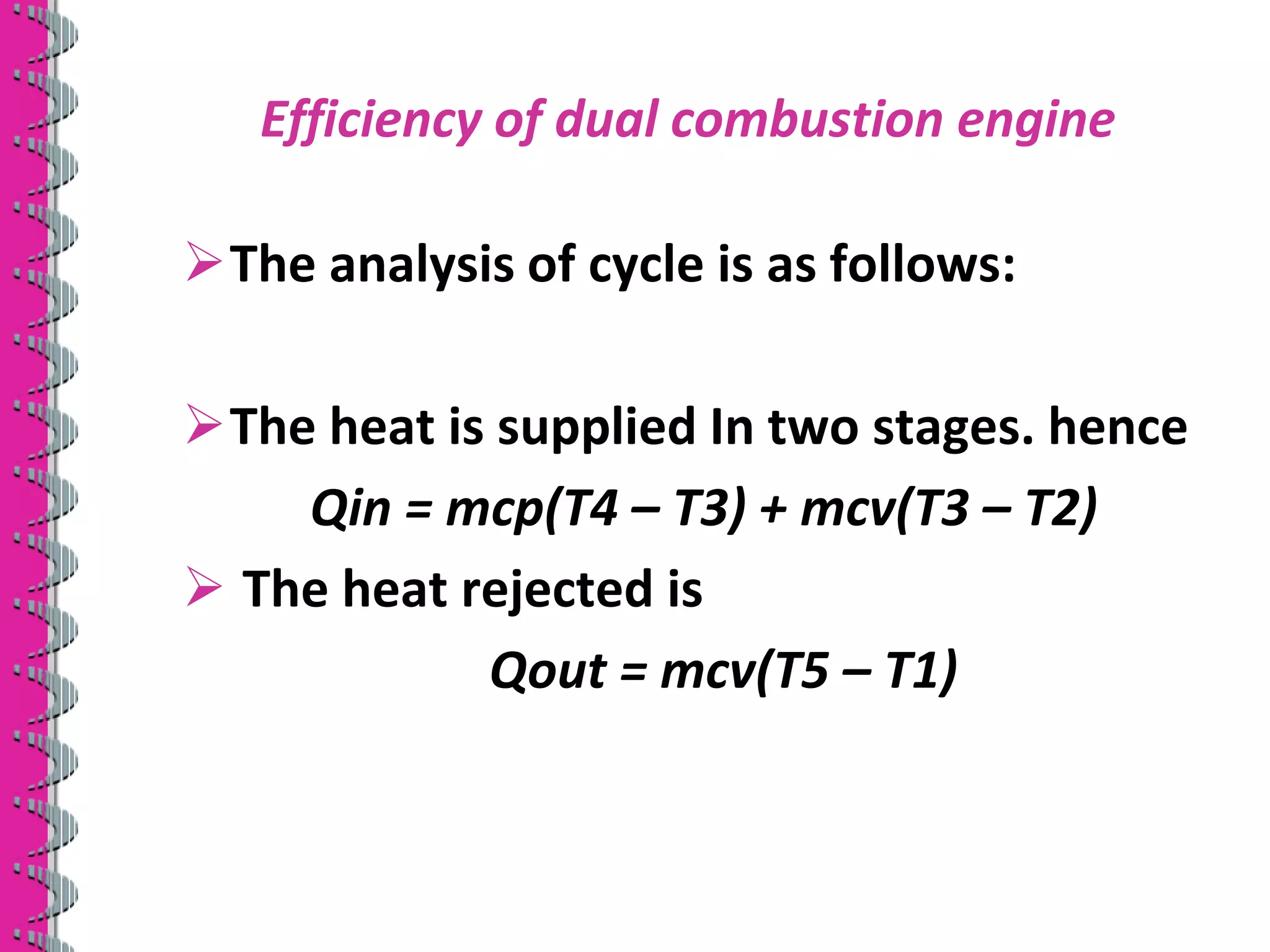

This document presents information about a dual combustion engine. It was presented to Sir Qazi Shehzad by five students. The document defines a dual combustion engine as a four-stroke internal combustion engine where combustion occurs in two parts, first at constant pressure and then at constant volume. This makes it more efficient than a diesel engine. It also describes the key parts of the engine, the combustion cycle process, an equation for calculating its thermal efficiency, and its applications in vehicles, generators, and potentially future energy systems.

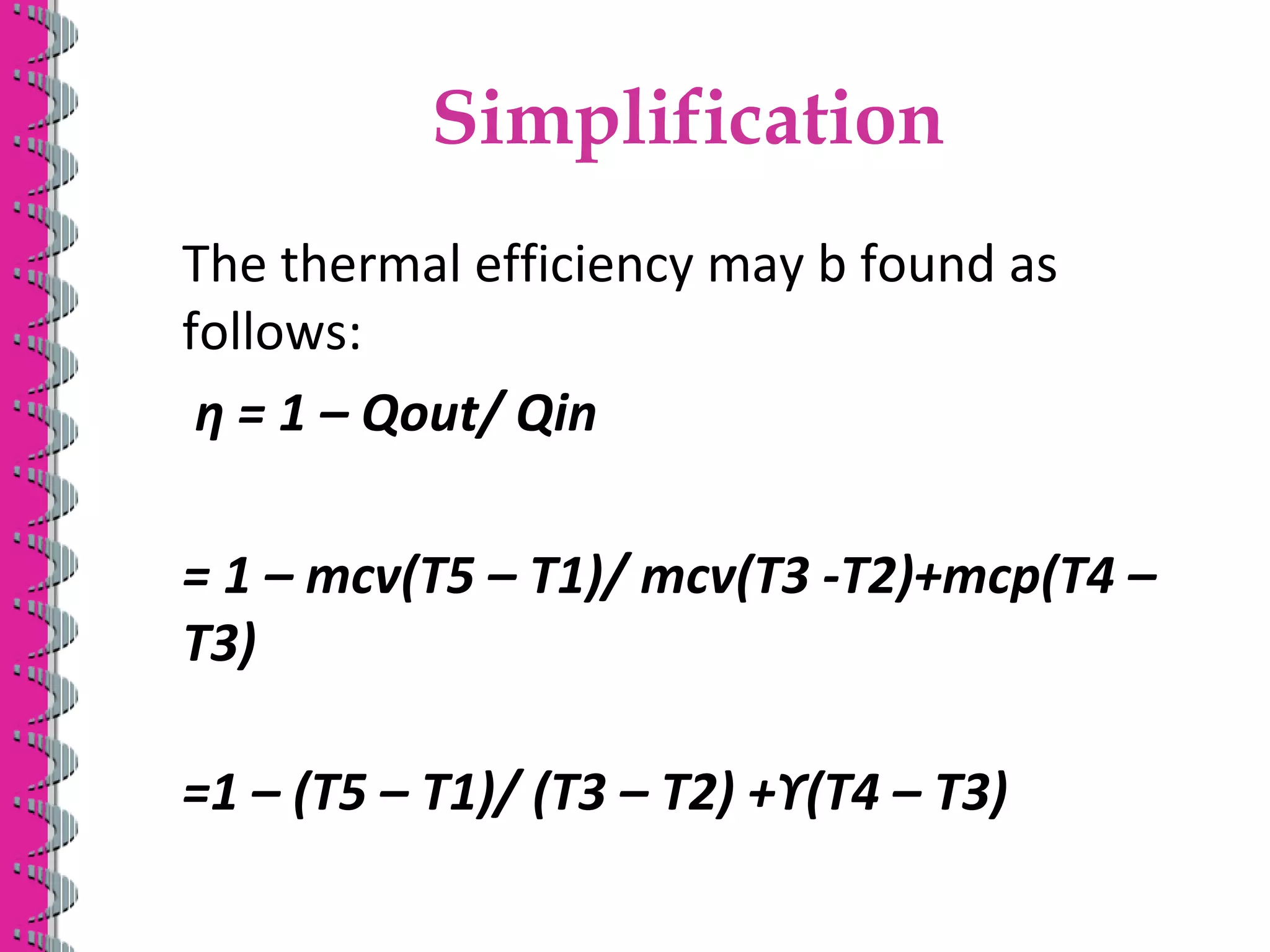

![Simplification Of Formulae

• The formula can be further developed to

show that:

η = 1-(kβγ -1)/[(k-1) +γk(β-1)]rv

γ-1

• rv is the VOLUME COMPRESSION RATIO.

• rv = V1/V2

• β is the CUT OFF RATIO.

• β = V4/V3

• k is the ratio p3/p2.

• If k=1 then it becomes Otto cycle’s

efficiency.](https://image.slidesharecdn.com/dualcombustioncycle-150203100905-conversion-gate02/75/Dual-combustion-cycle-19-2048.jpg)