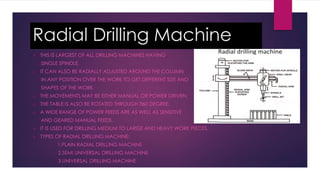

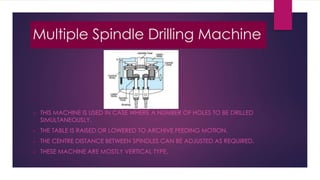

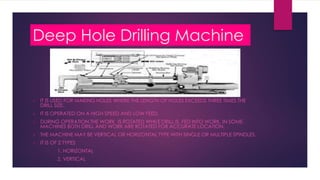

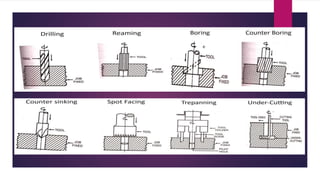

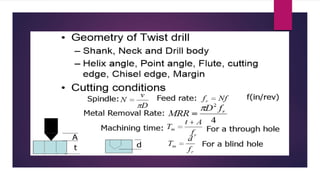

The document discusses different types of drilling machines. It describes the main parts of drilling machines including the vice, spindle, sleeve, column, head, worktable and base. It then covers different types of drilling machines such as portable, bench-mounted, sensitive, upright, radial, gang, multiple spindle, automatic, and deep hole drilling machines. It provides details on radial drilling machines and their applications in underground mining, surface mining, drilling and other operations.

![SCIENCE

ASSIGNMENT :

DRILLING MACHINE

SUBMITTED TO: MR. VIRAT KHANNA

SUBMITTED BY:

(ASST. PROFESSOR)

VIKAS SHARMA

B.TECH [M.E.]

MAU13UME057](https://image.slidesharecdn.com/drillingmachine-150310141936-conversion-gate01/75/Drilling-machines-in-detail-1-2048.jpg)