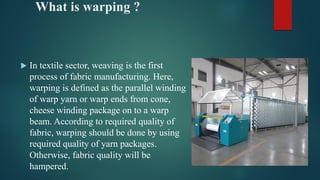

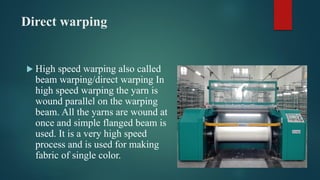

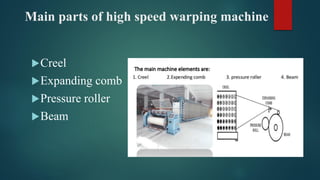

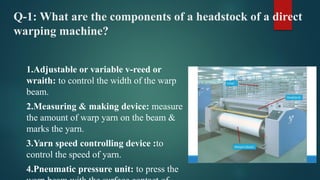

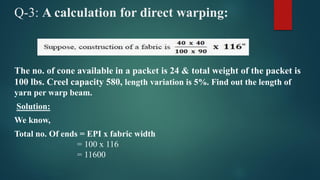

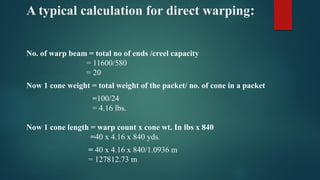

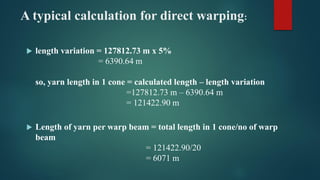

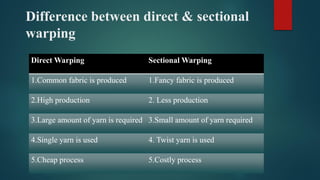

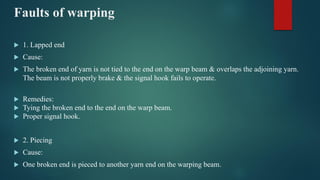

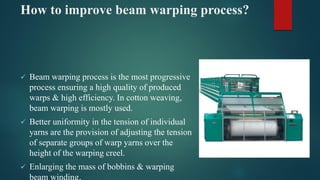

This document discusses warping, which is the process of winding warp yarn parallel onto a warp beam in textile manufacturing. It defines warping and describes the requirements, such as uniform spacing and tension of ends. It discusses different types of warping like direct/beam warping and sectional warping. Direct warping is described as a high-speed process using a simple beam suitable for single-color fabrics. The components and working principle of a direct warping machine are explained. Advantages like high production and disadvantages like unsuitability for stripe fabrics are provided. Calculations for determining yarn length per beam are shown. Common warping faults and how to improve the beam warping process are also covered.