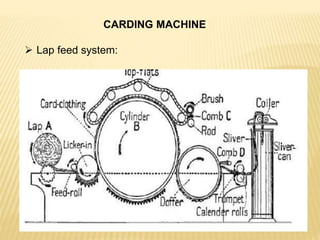

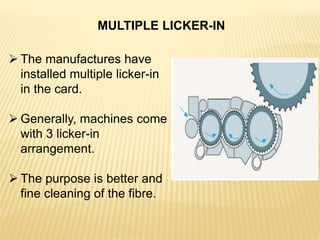

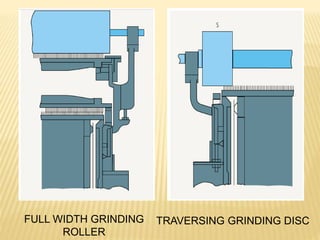

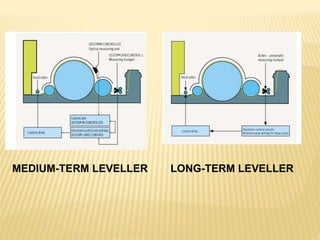

The document discusses the carding process in textile manufacturing, highlighting its role in cleaning and preparing fibers for further processing. It details advancements in carding machines, including improved feed systems, increased production rates, and integrated grinding systems, which enhance efficiency and fiber quality. It also addresses the importance of dust extraction systems for maintaining safe working conditions.