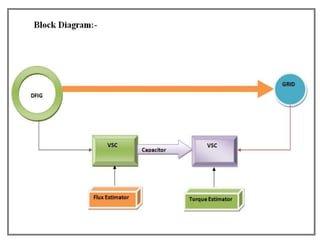

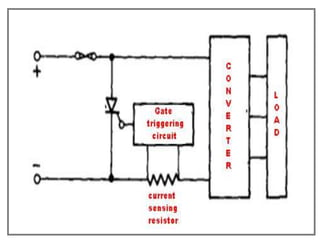

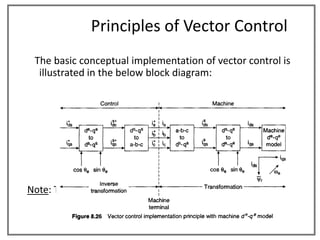

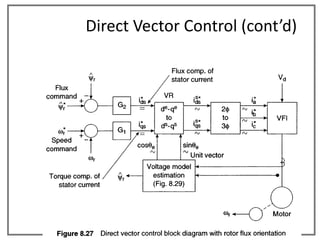

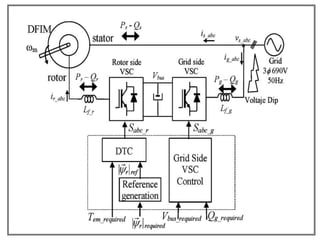

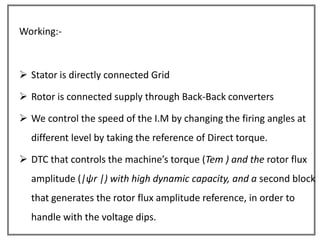

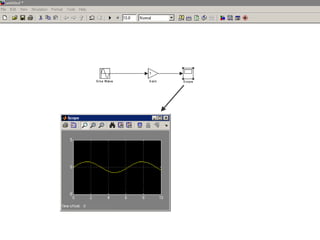

This document proposes a direct torque control strategy for doubly fed induction machine-based wind turbines that can operate under voltage dips without crowbar protection. The control strategy generates a rotor flux amplitude reference to control the torque of the wind turbine and reduce stator and rotor overcurrents during faults. It also provides fast dynamic response. While the control does not eliminate the need for crowbar protection entirely, it can prevent the crowbar from activating during low-depth voltage dips. The direct torque control approach maintains machine connection to the grid and reduces torque oscillations during faults.