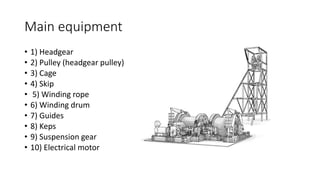

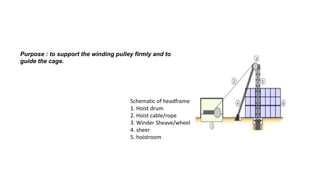

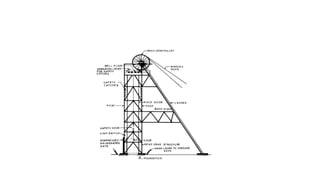

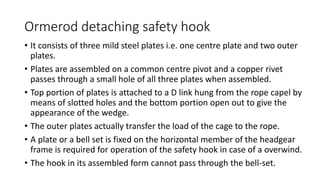

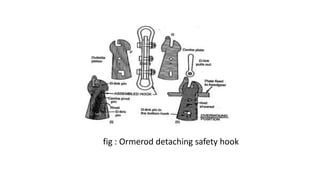

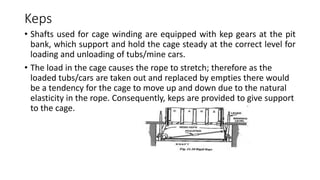

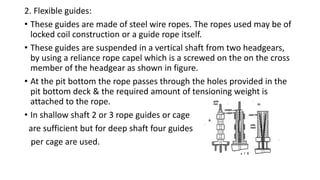

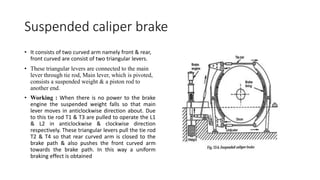

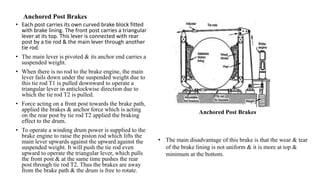

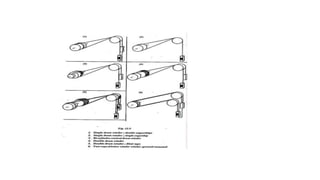

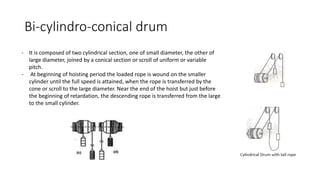

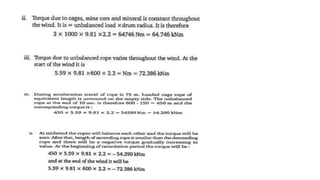

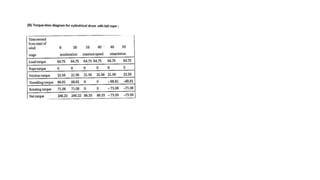

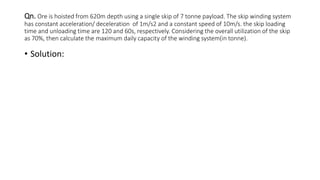

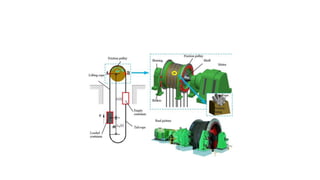

The document describes the mining machinery winding system, which primarily functions to hoist coal or minerals from underground and transport materials. It outlines the main equipment involved in this system, such as the headgear, cage, skip, and winding drum, along with their specifications and roles in the process. Additionally, it discusses safety devices, mechanical brakes, and comparisons between different types of guides and drums used in winding systems.