This document discusses various topics related to job design and work systems, including:

1. It defines job design as specifying the contents and methods of jobs, considering factors like who, what, how, where, and ergonomics.

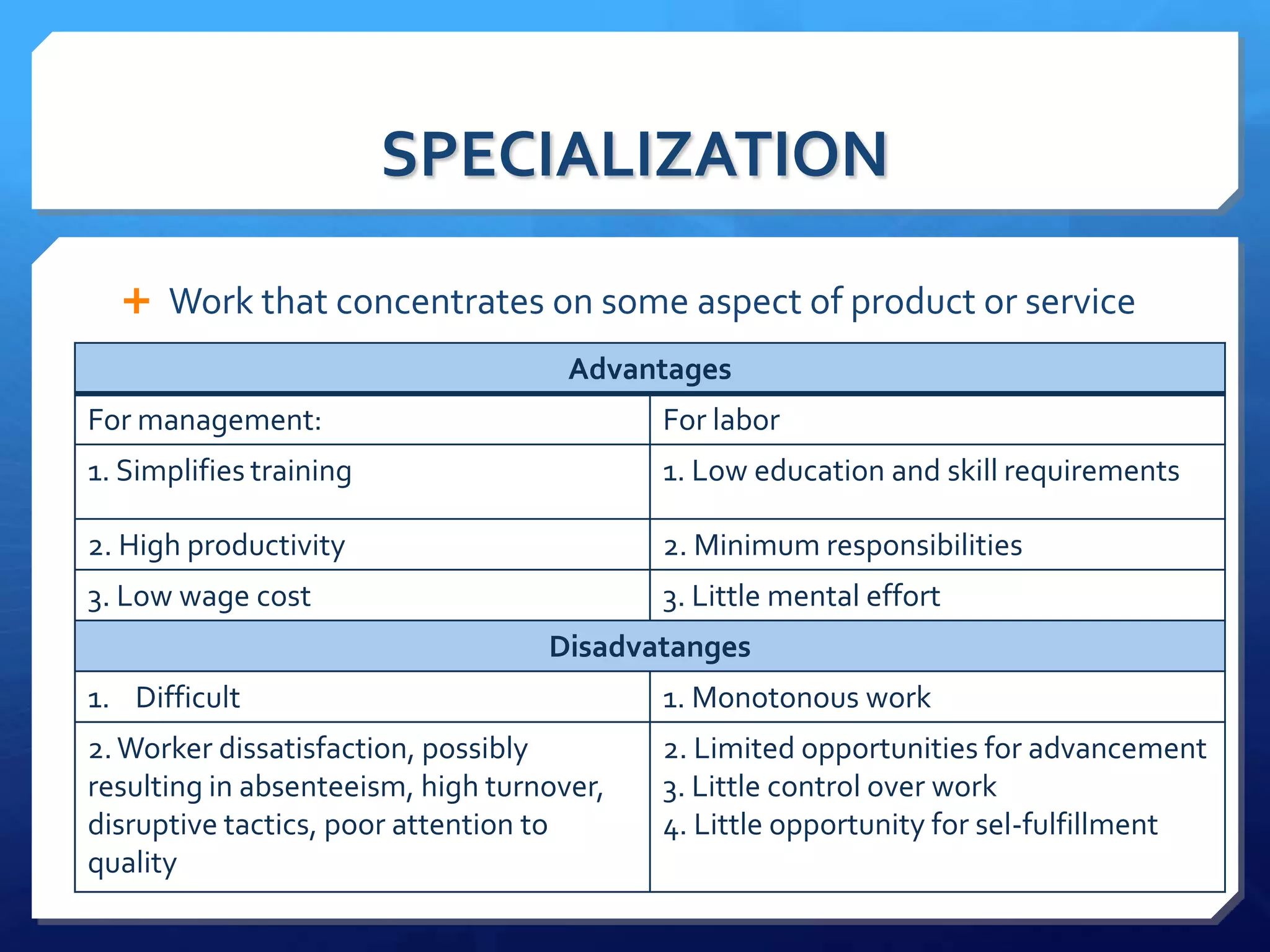

2. It discusses approaches to job design like specialization, job enlargement, job rotation, and job enrichment aimed at improving worker satisfaction and motivation.

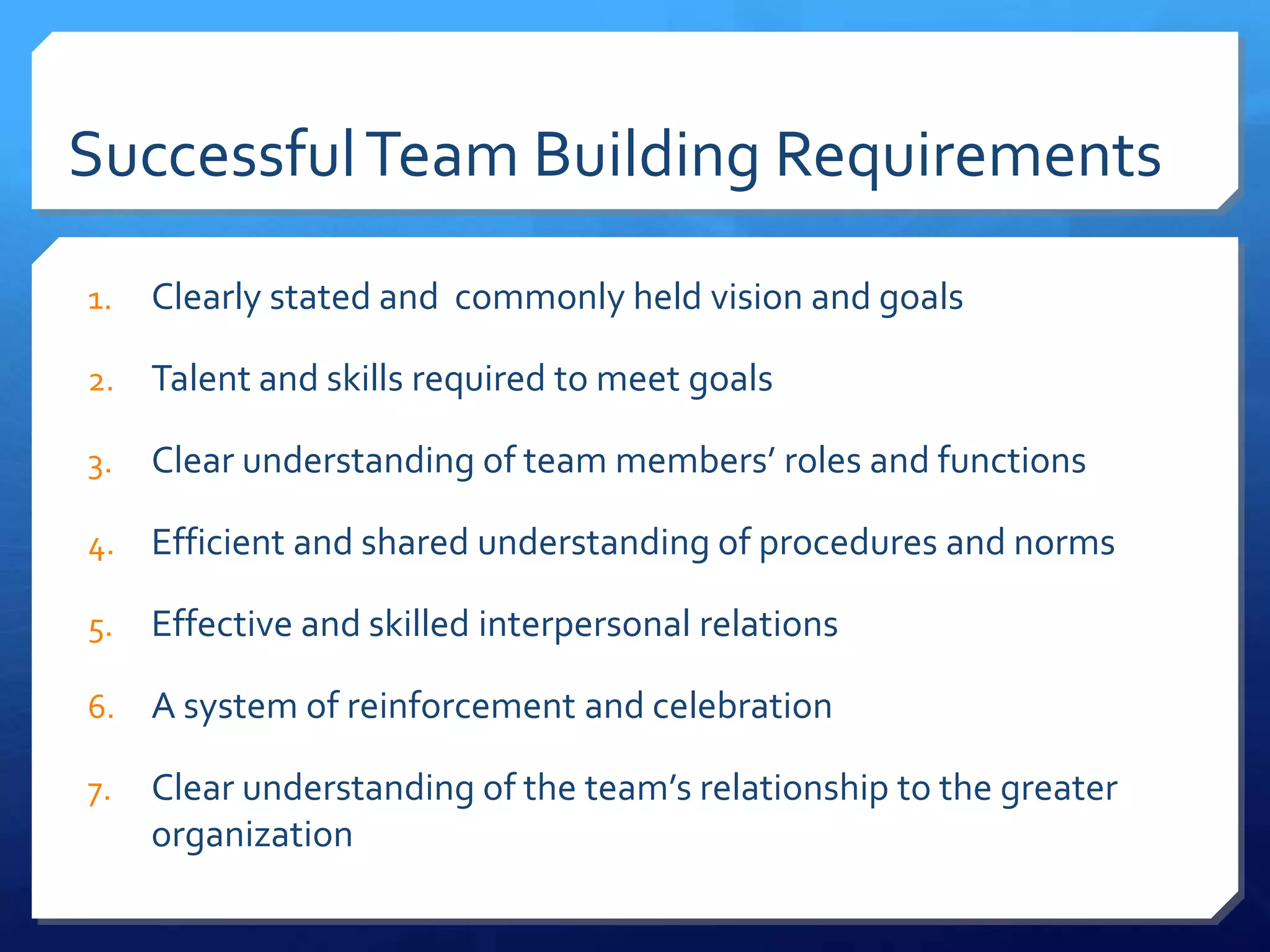

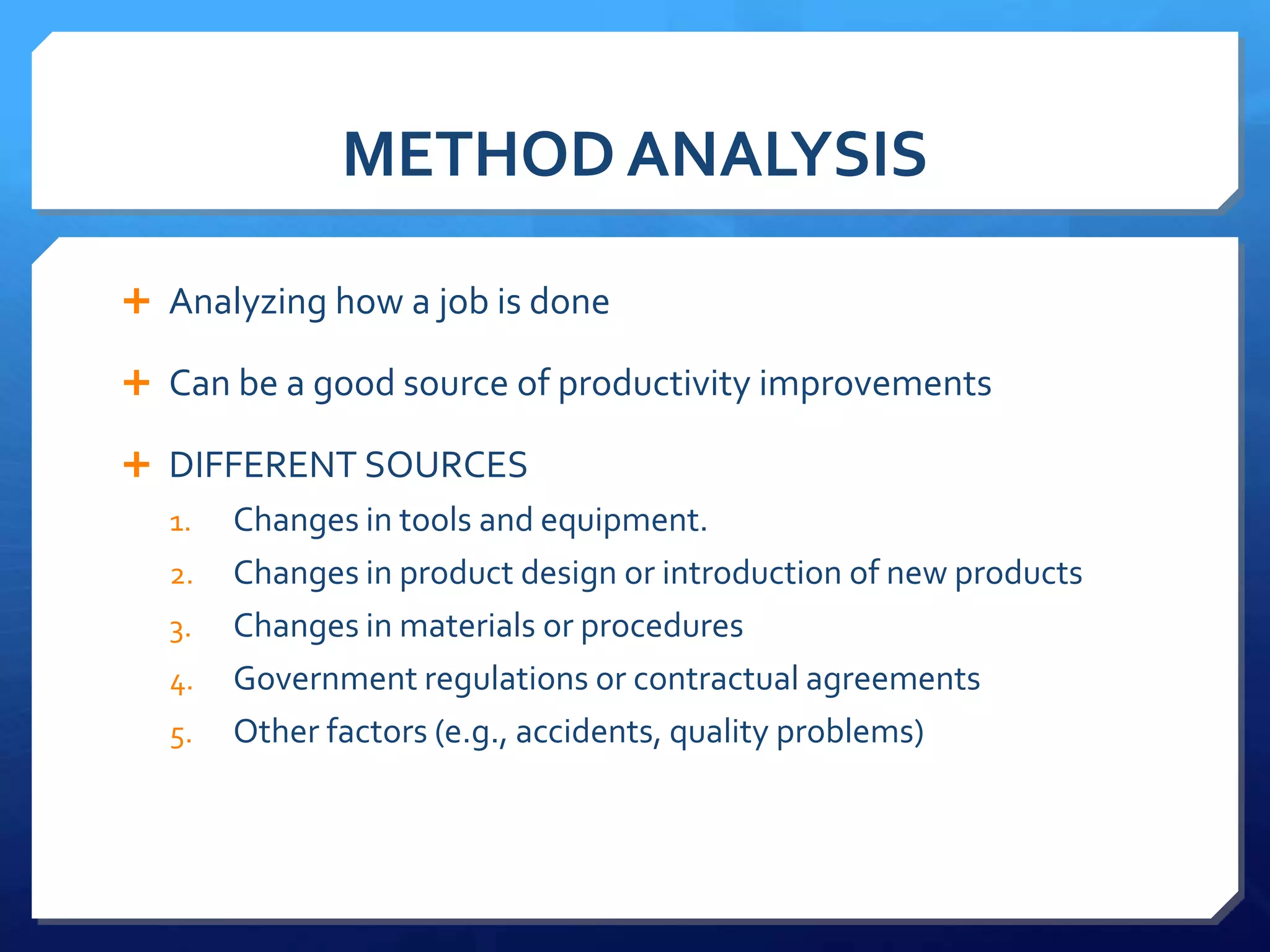

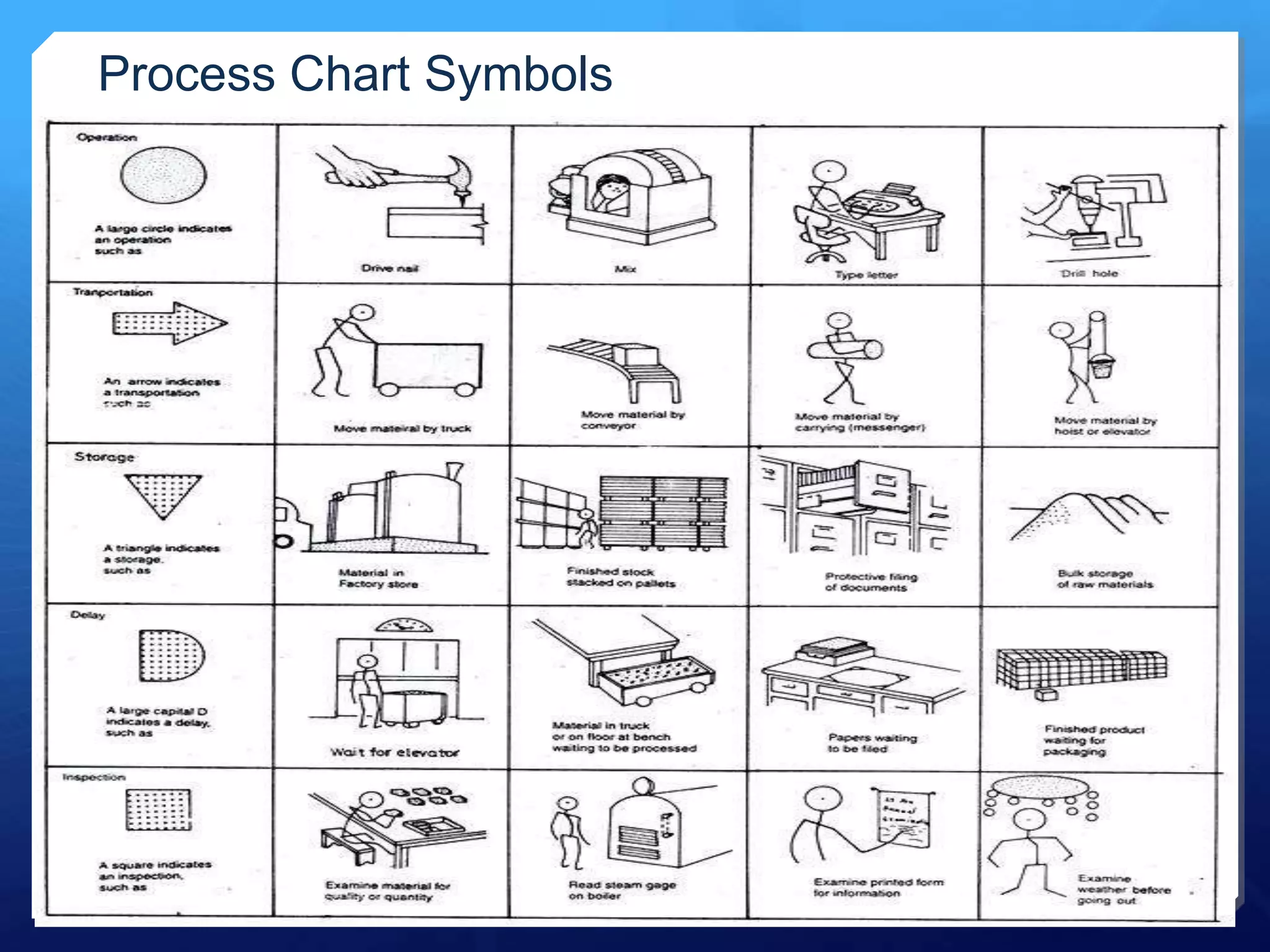

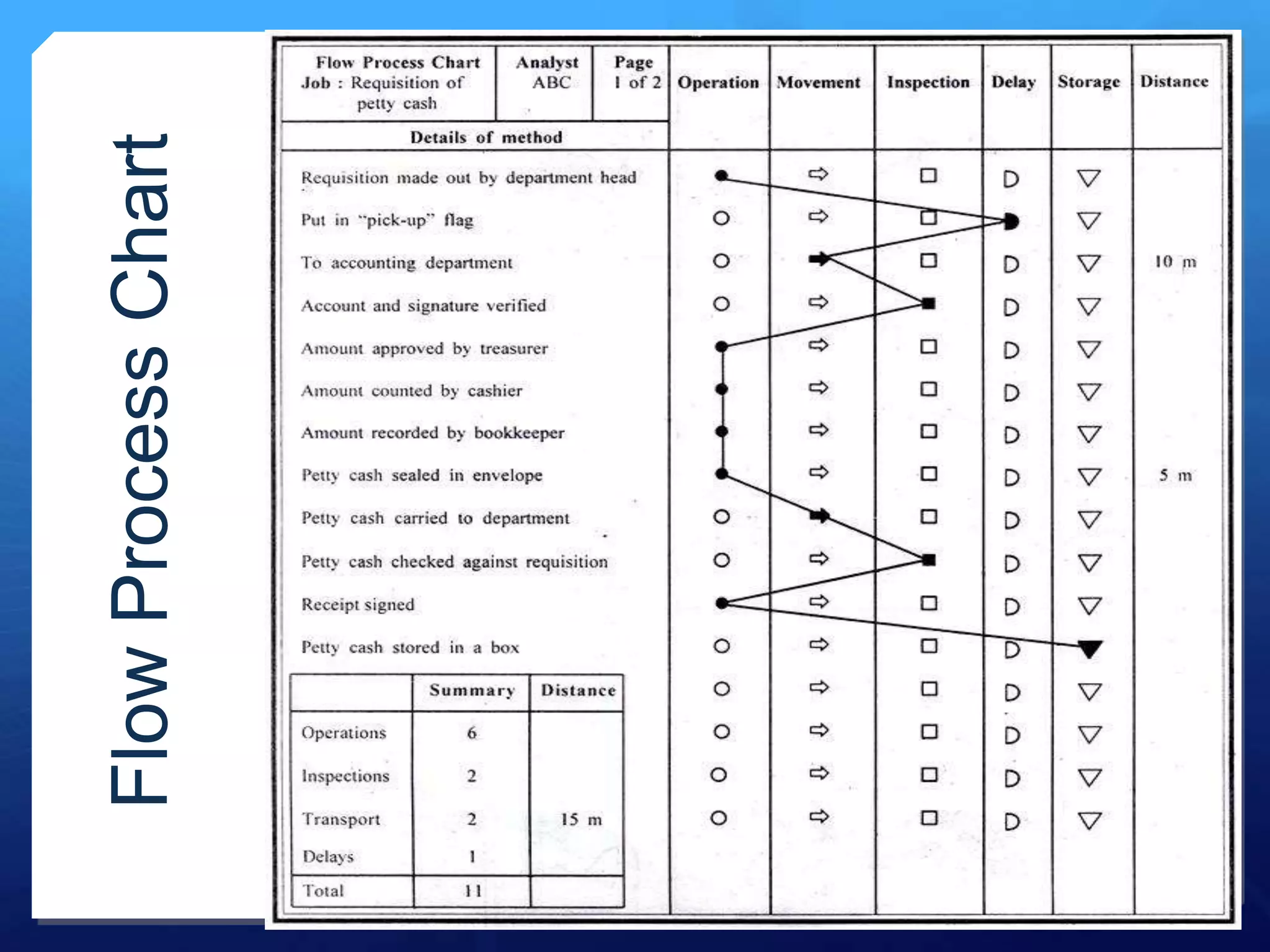

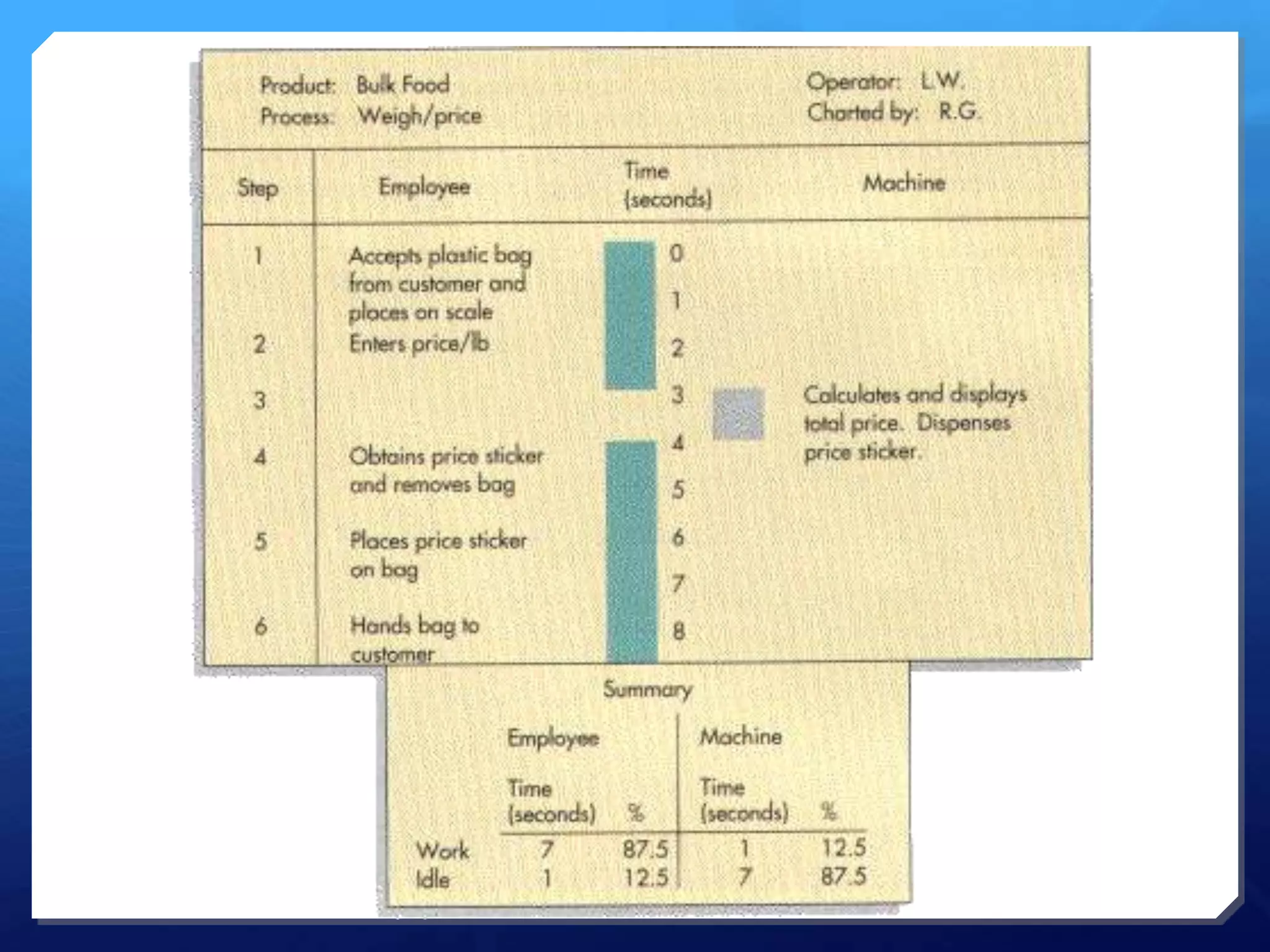

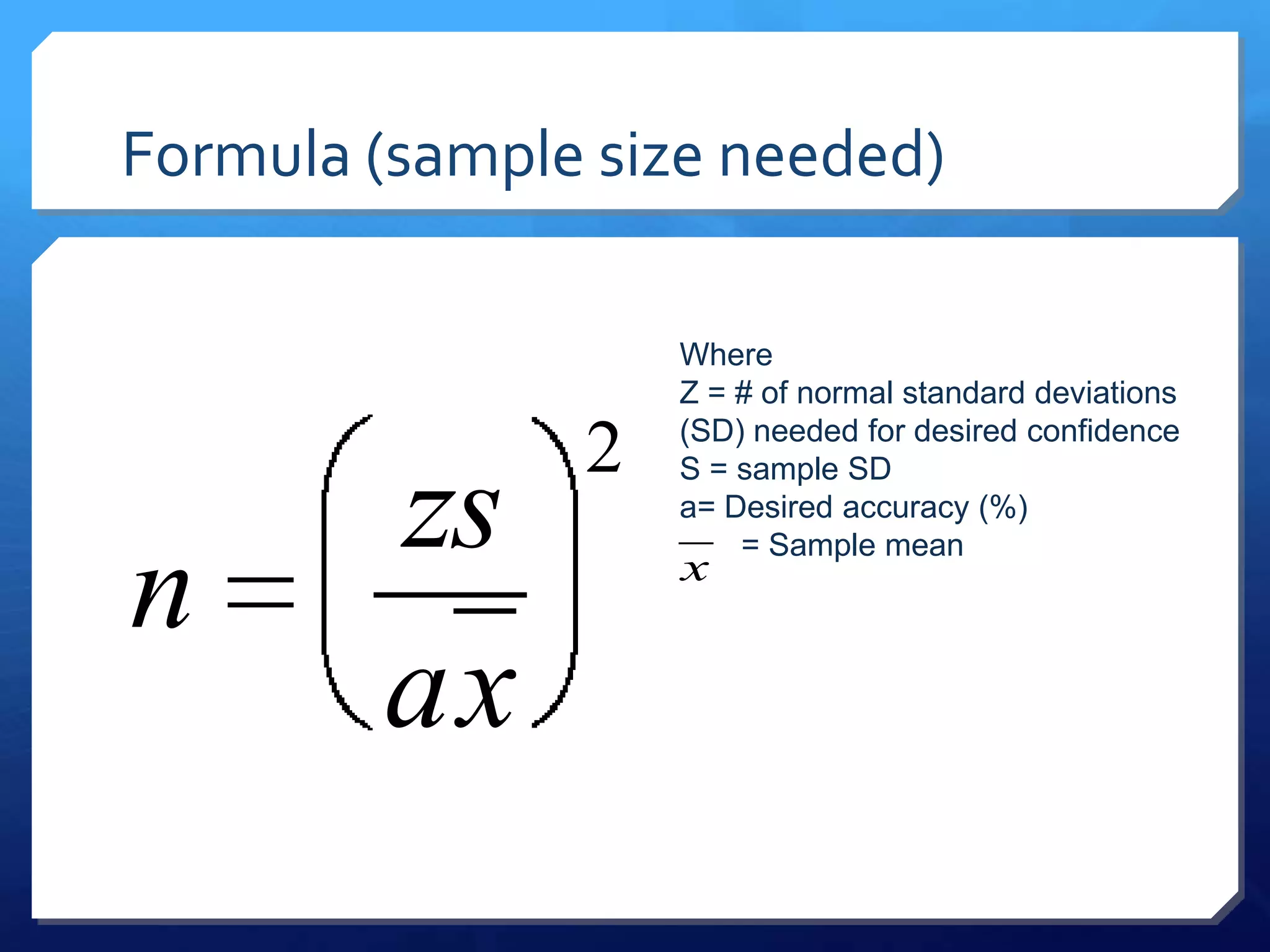

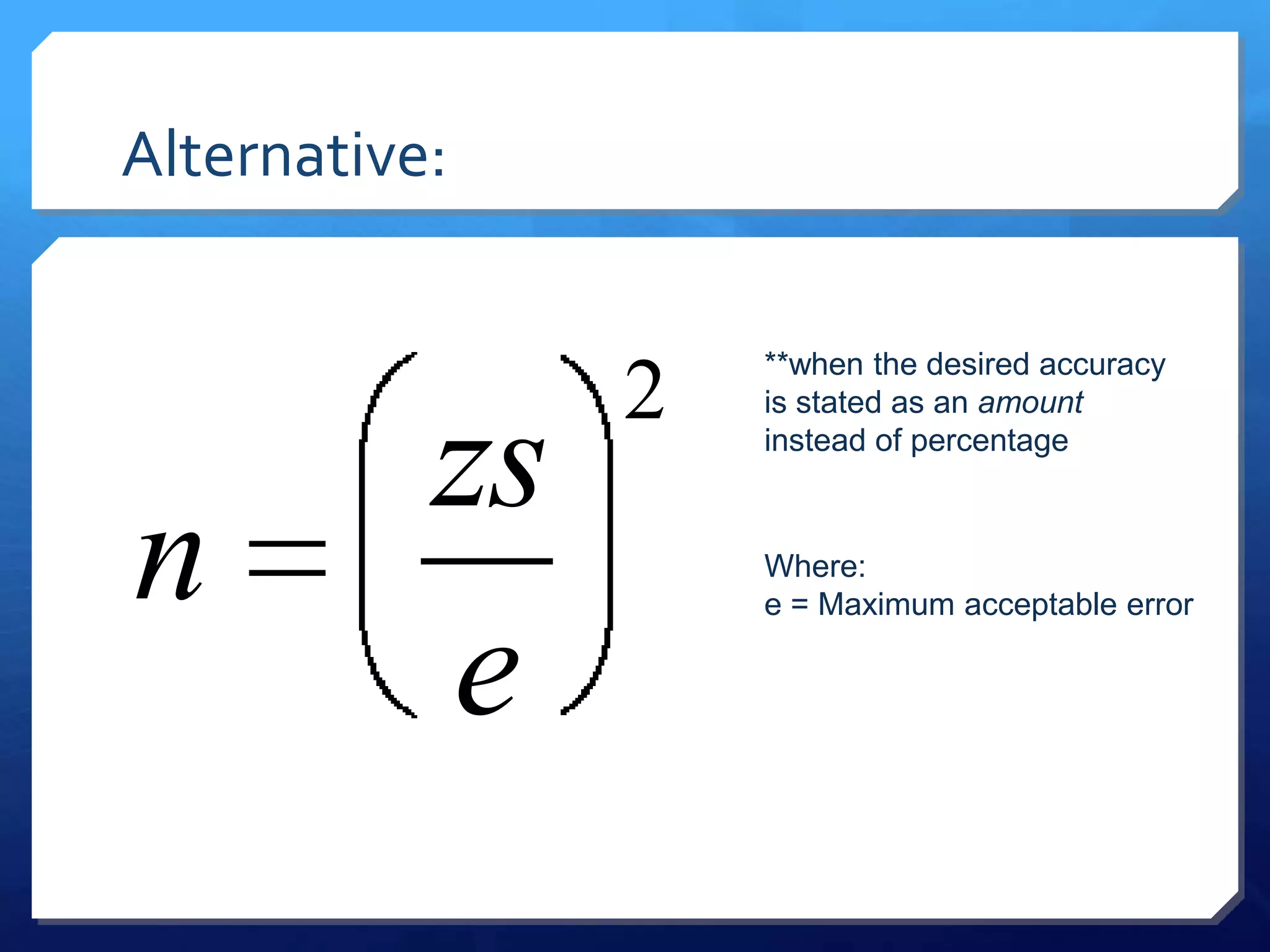

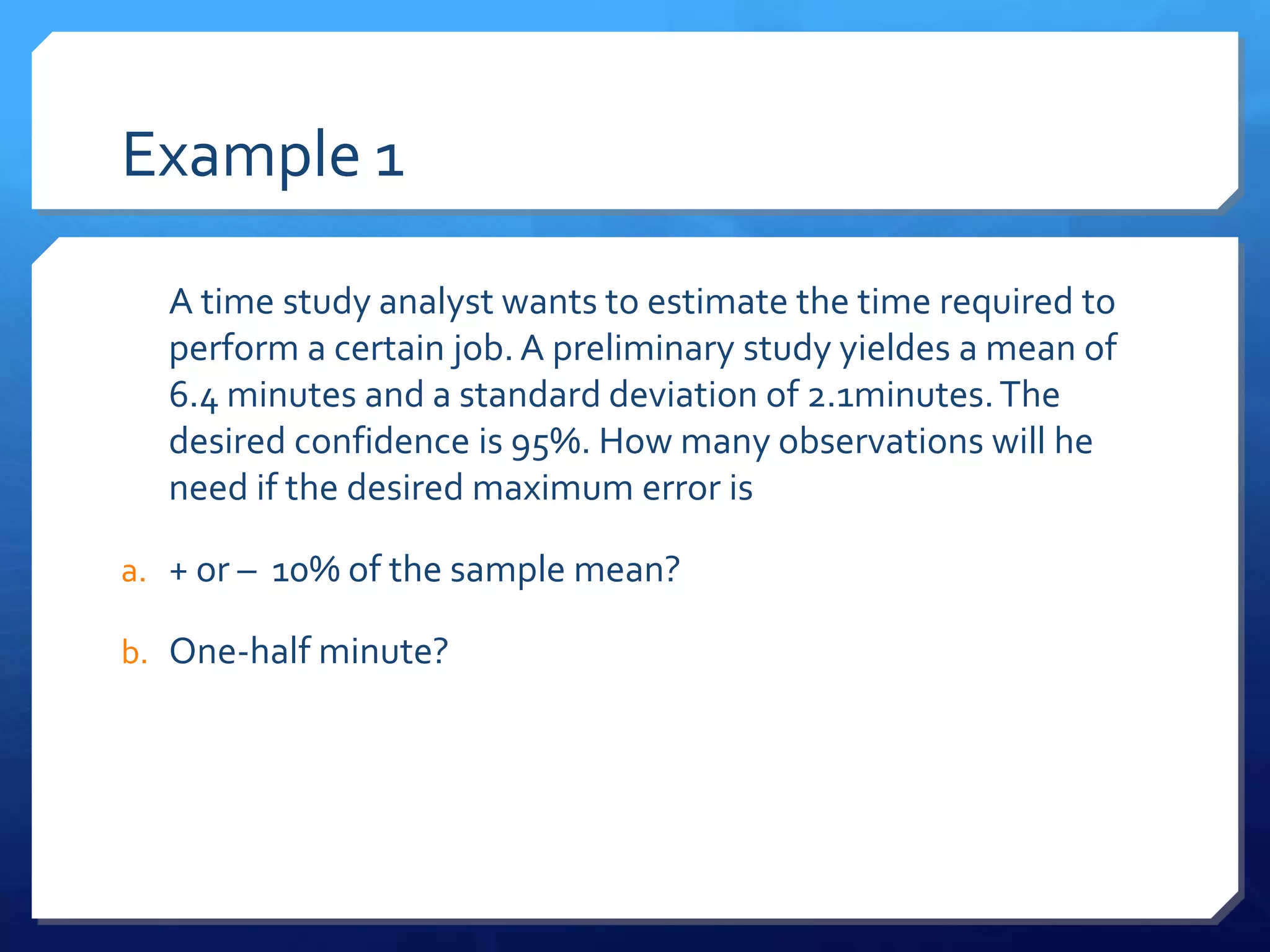

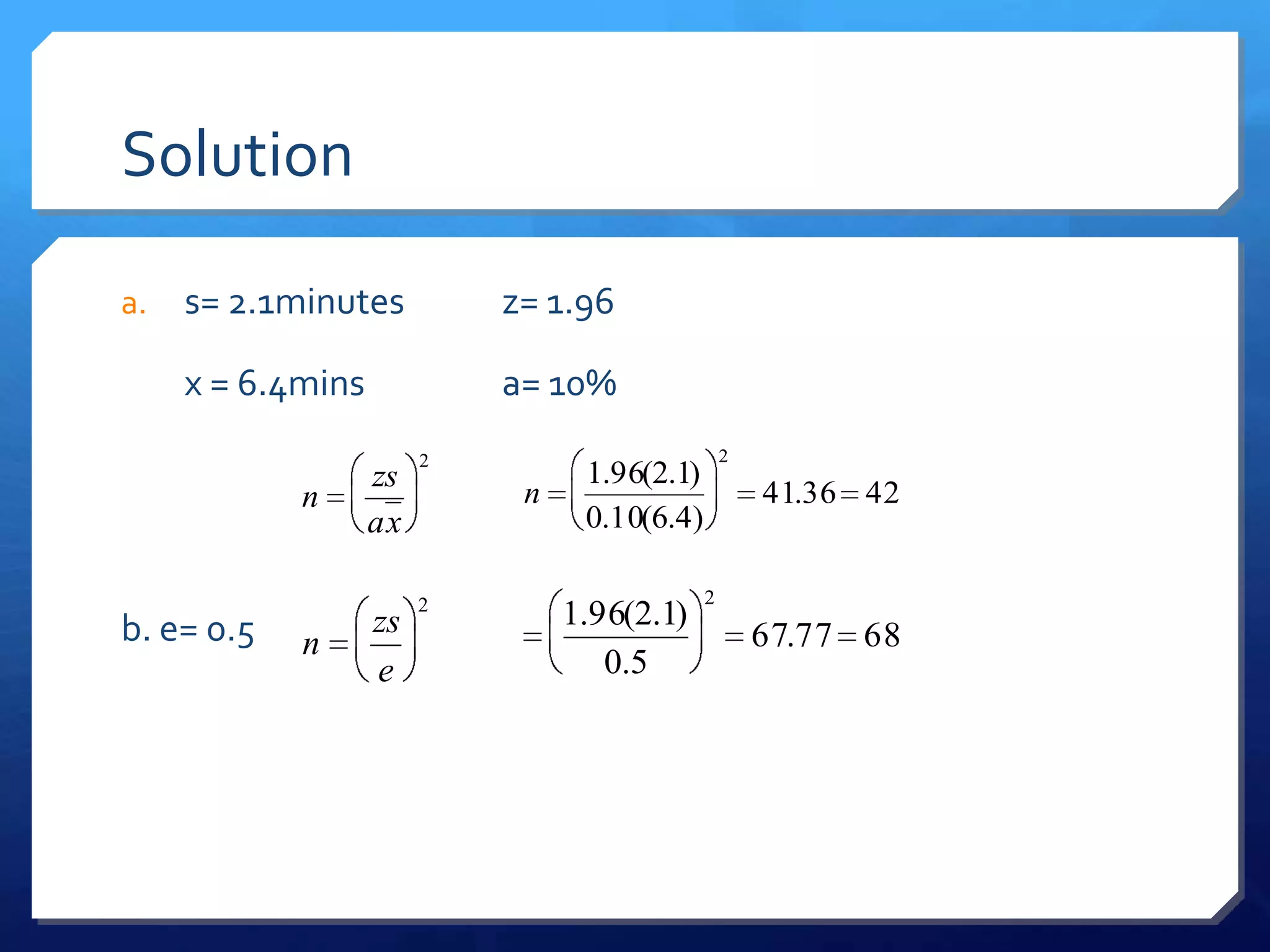

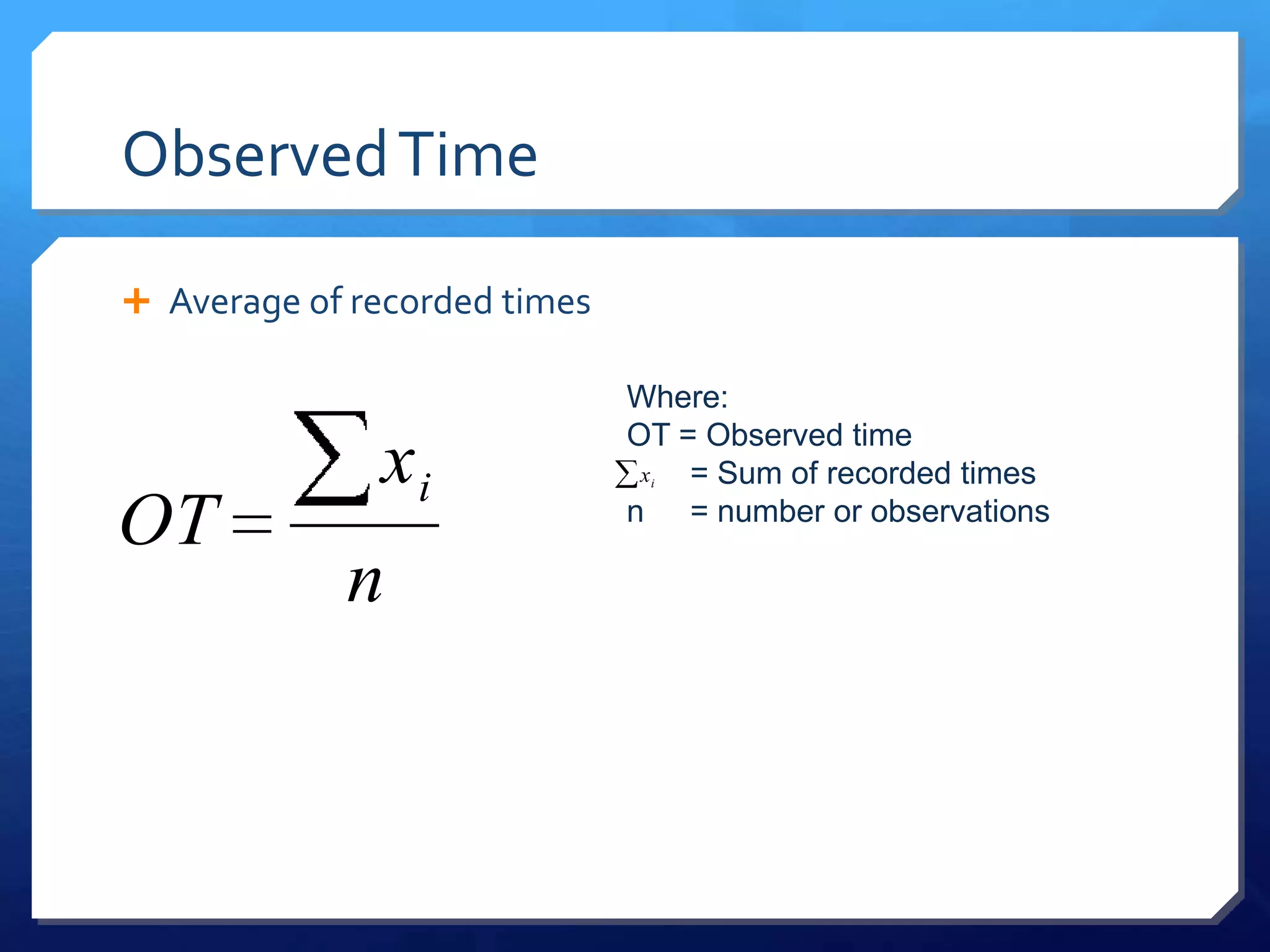

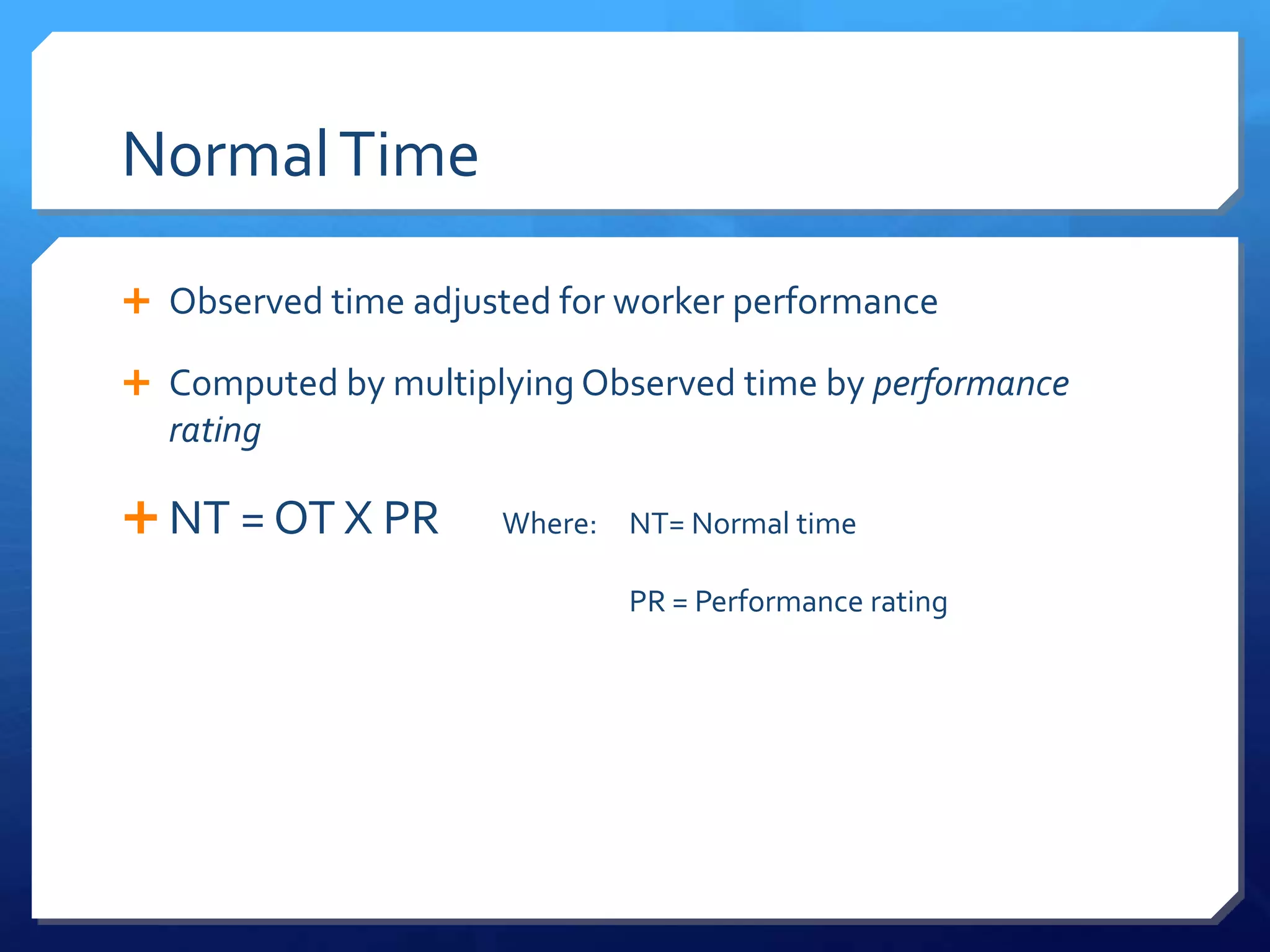

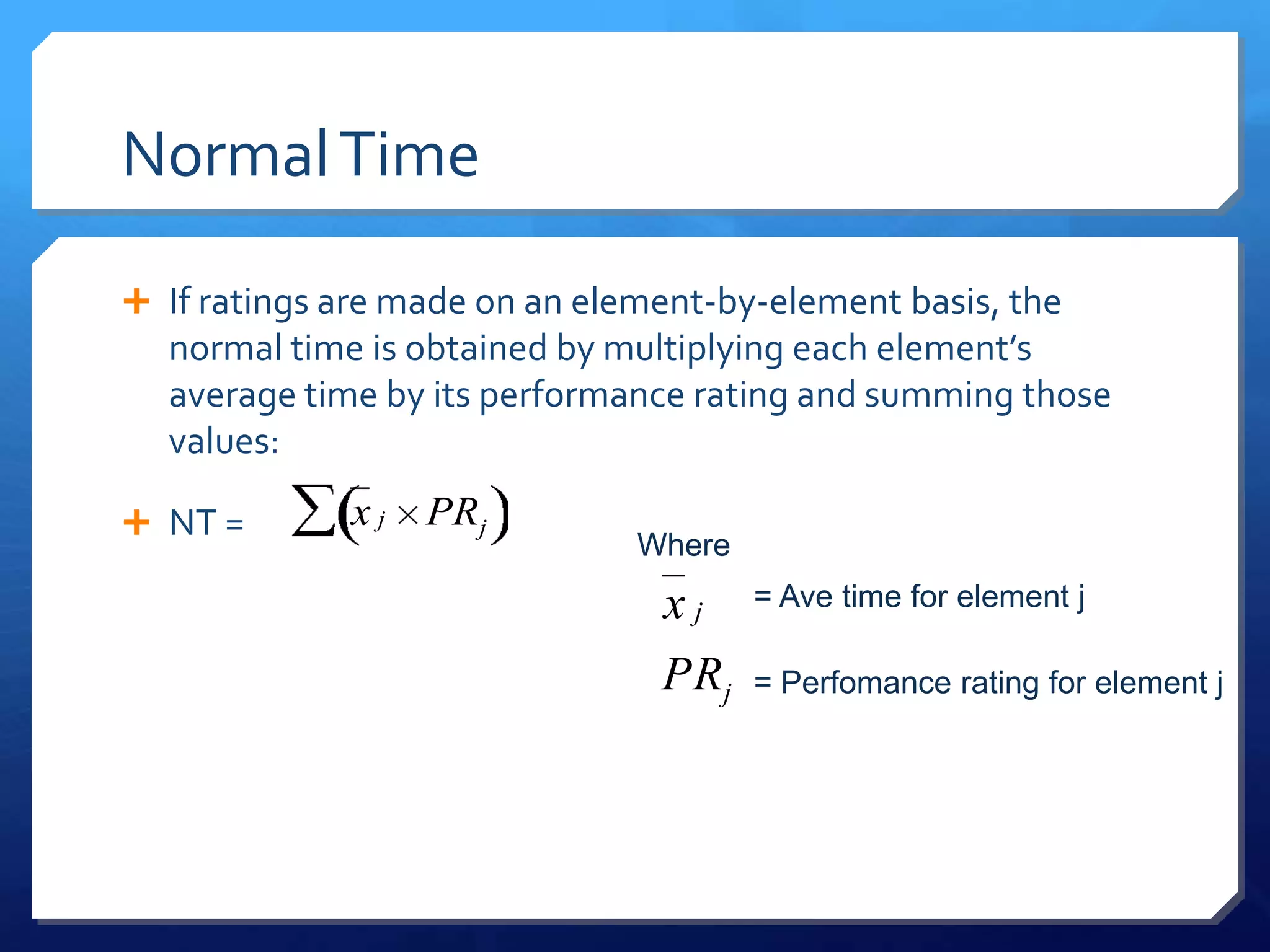

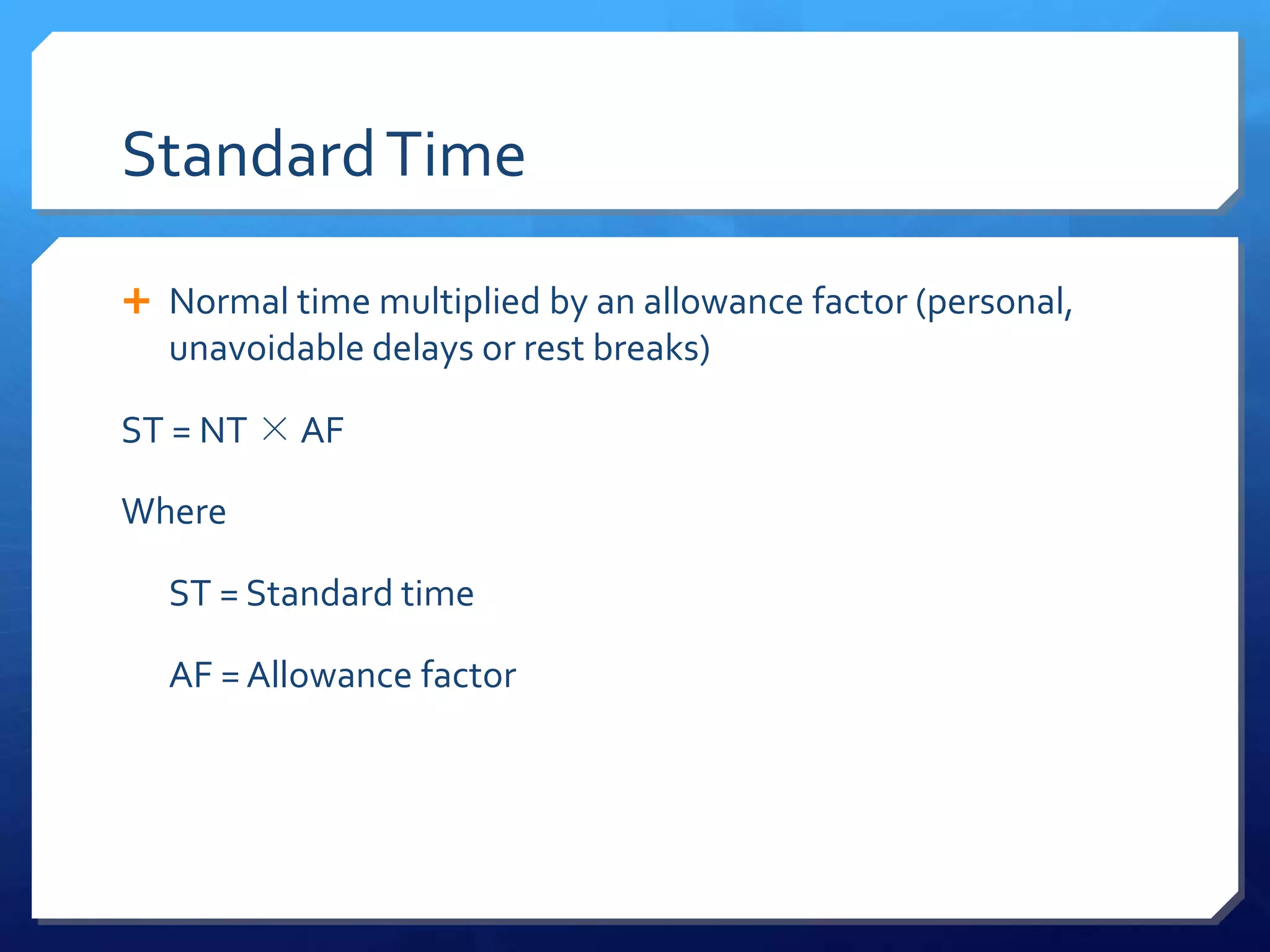

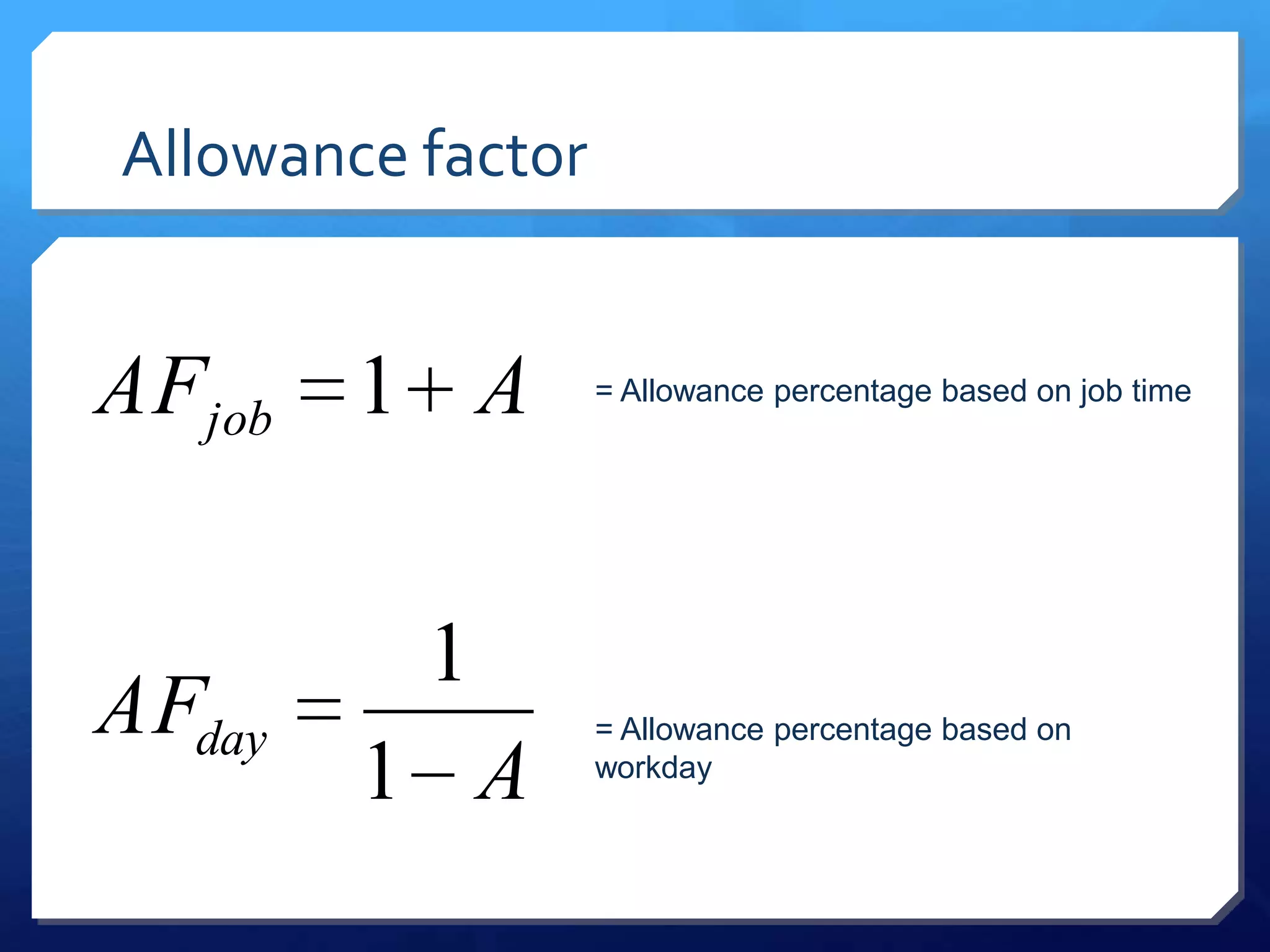

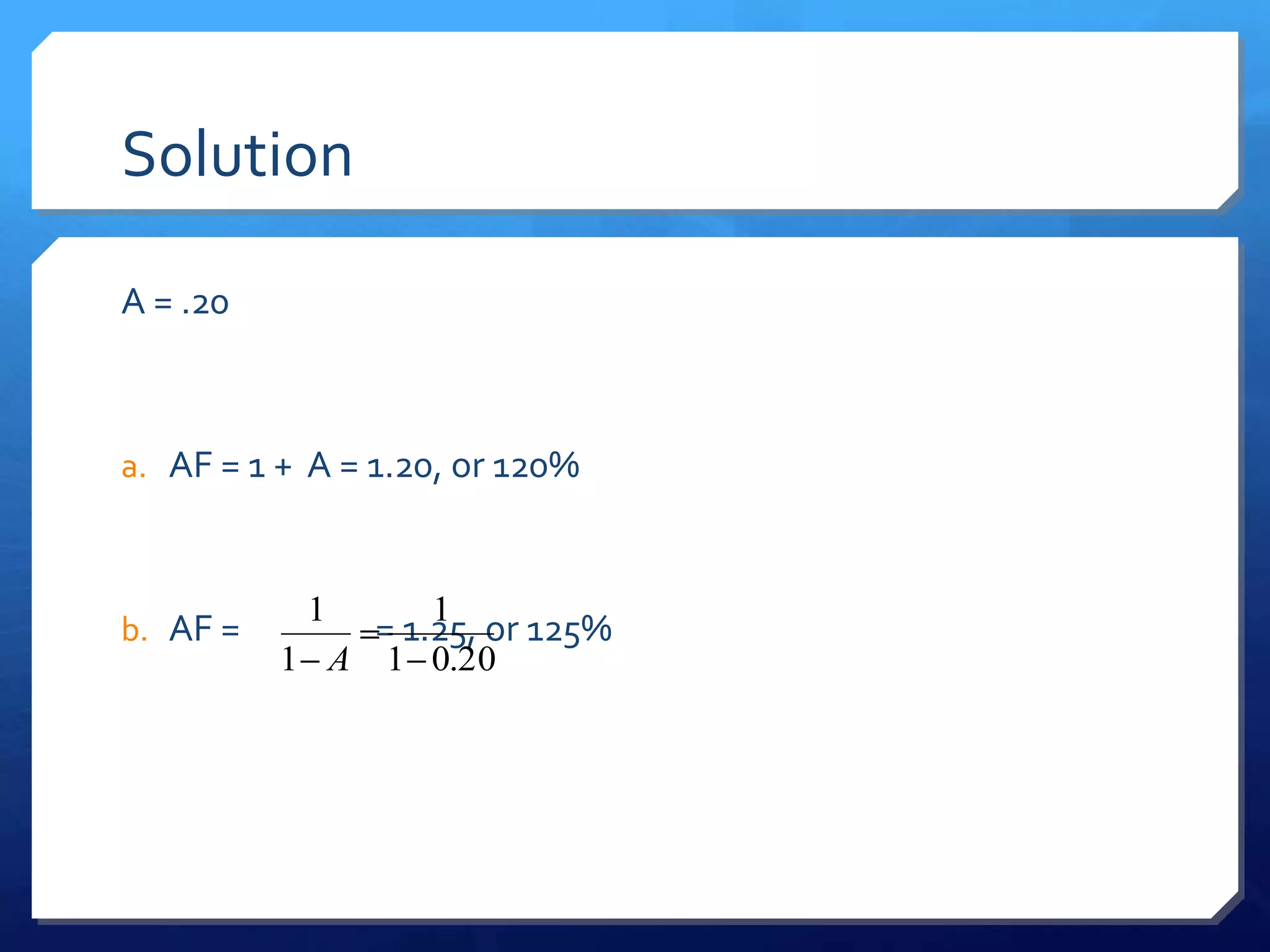

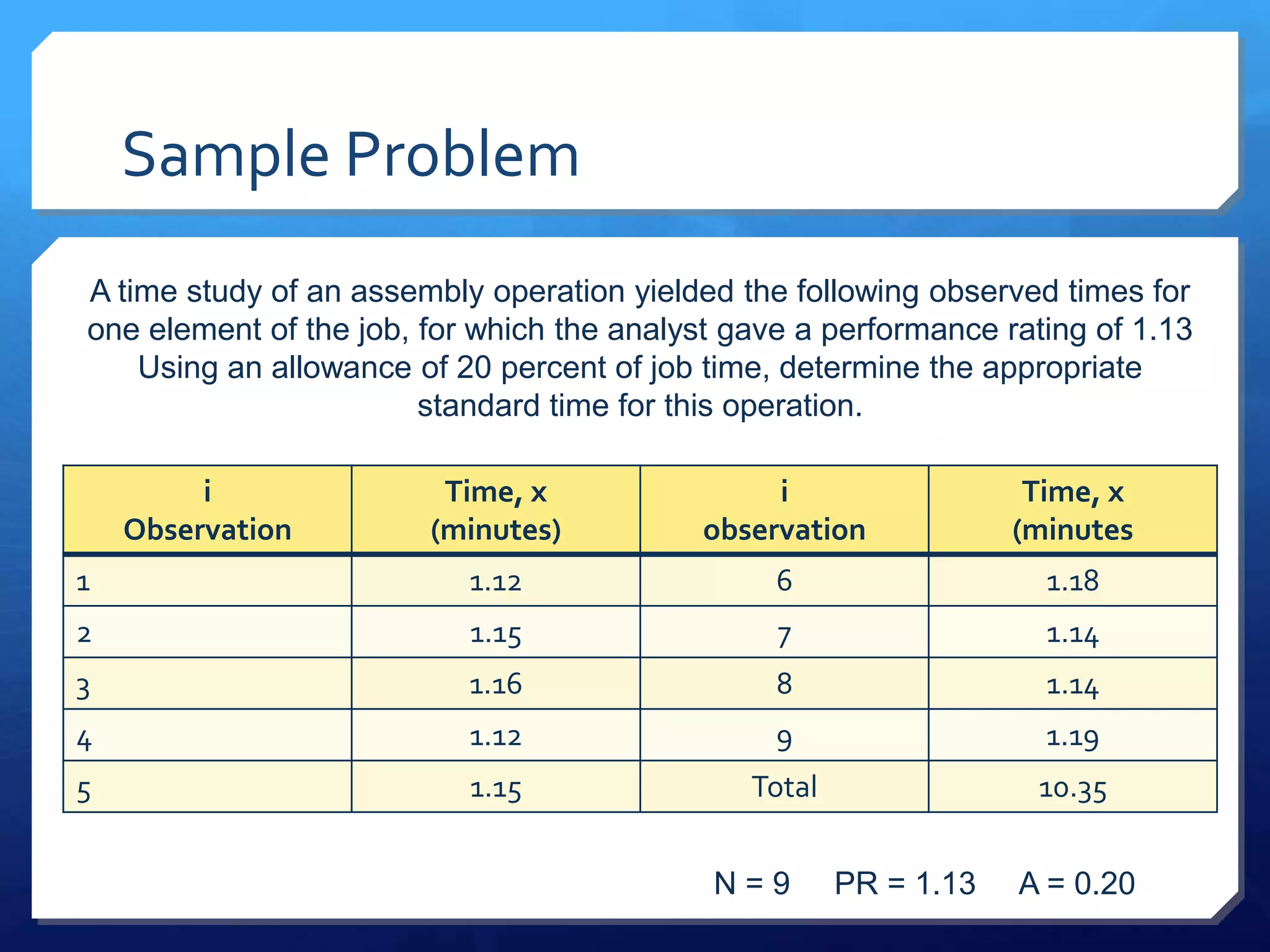

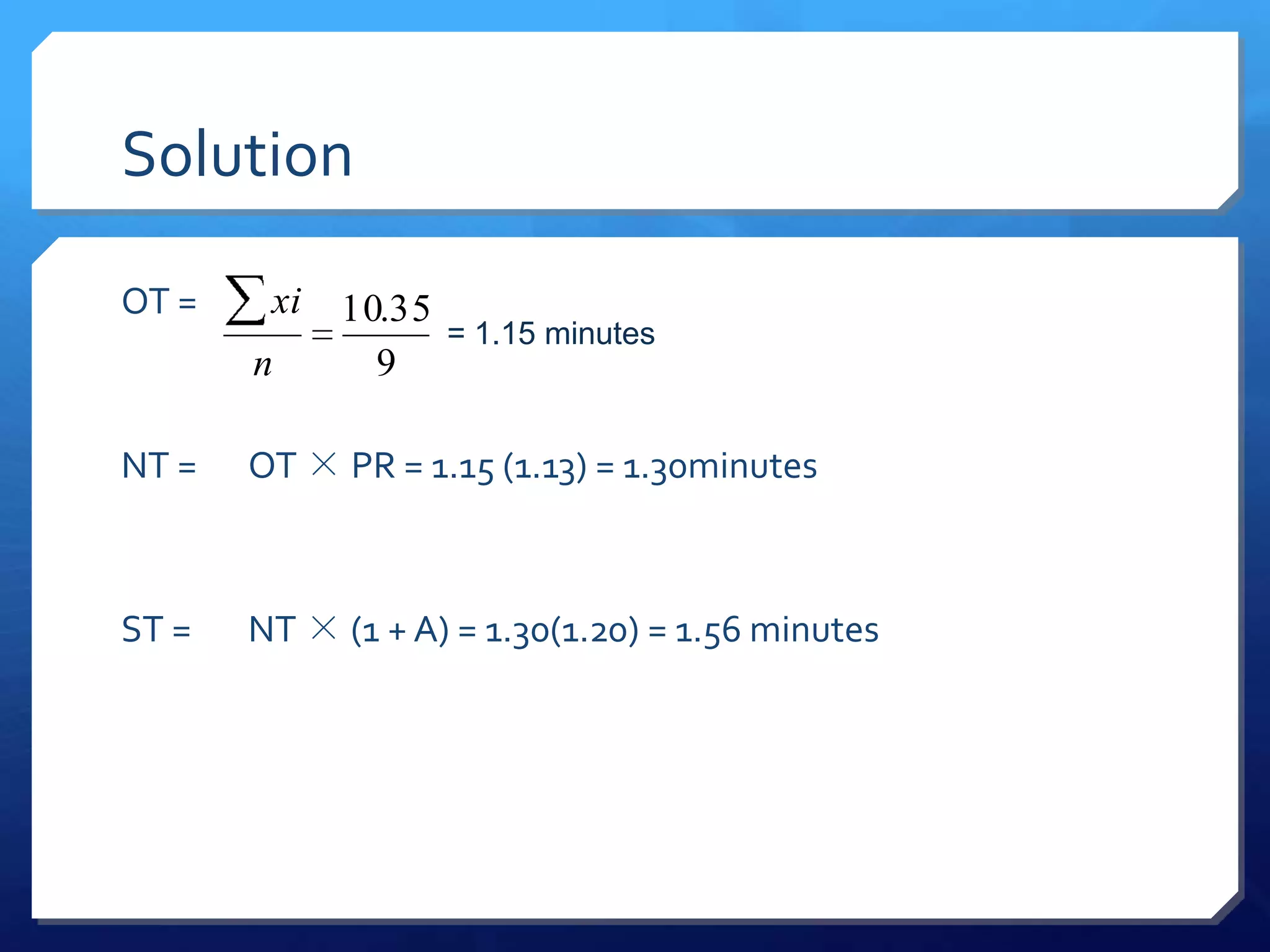

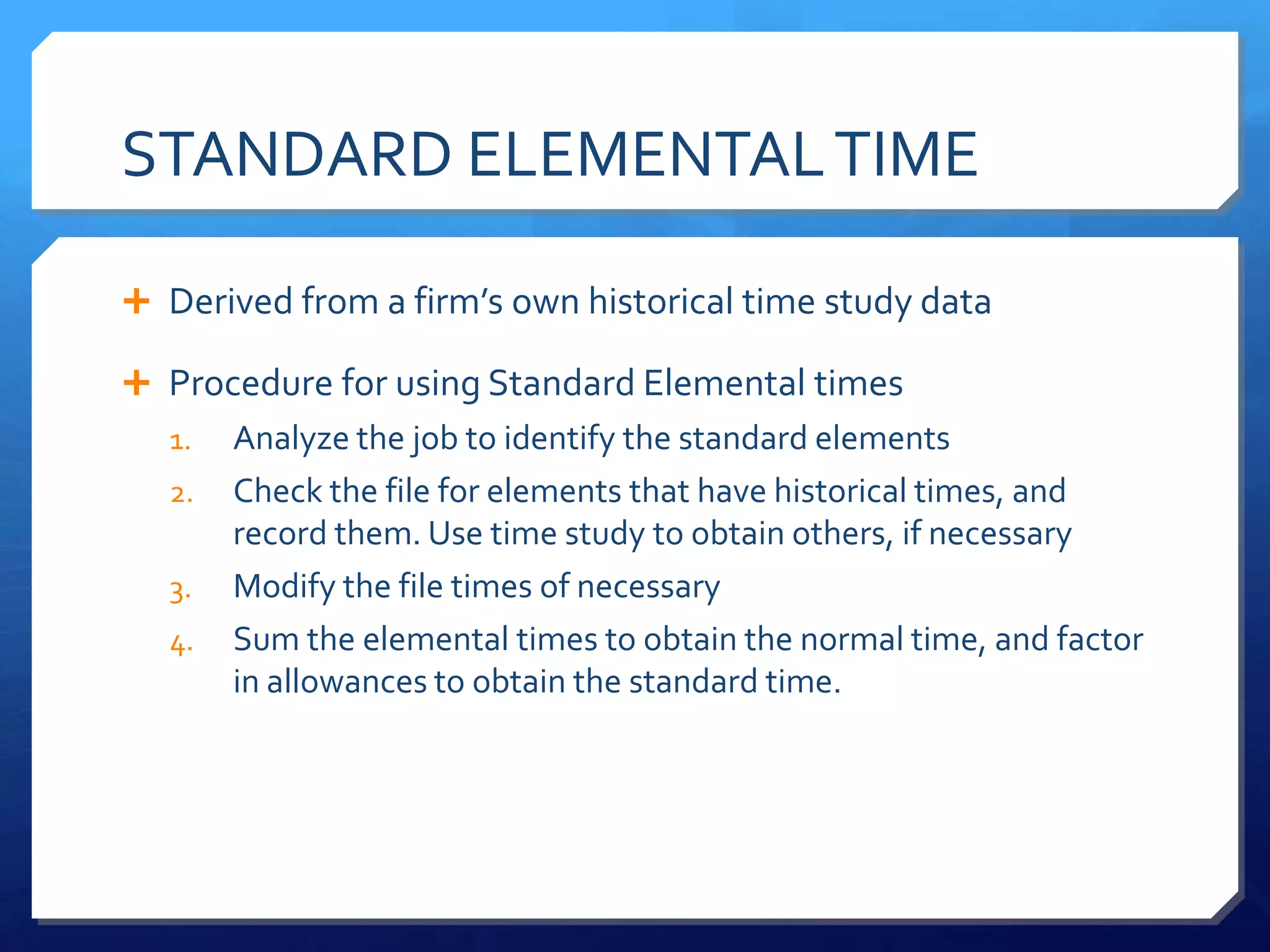

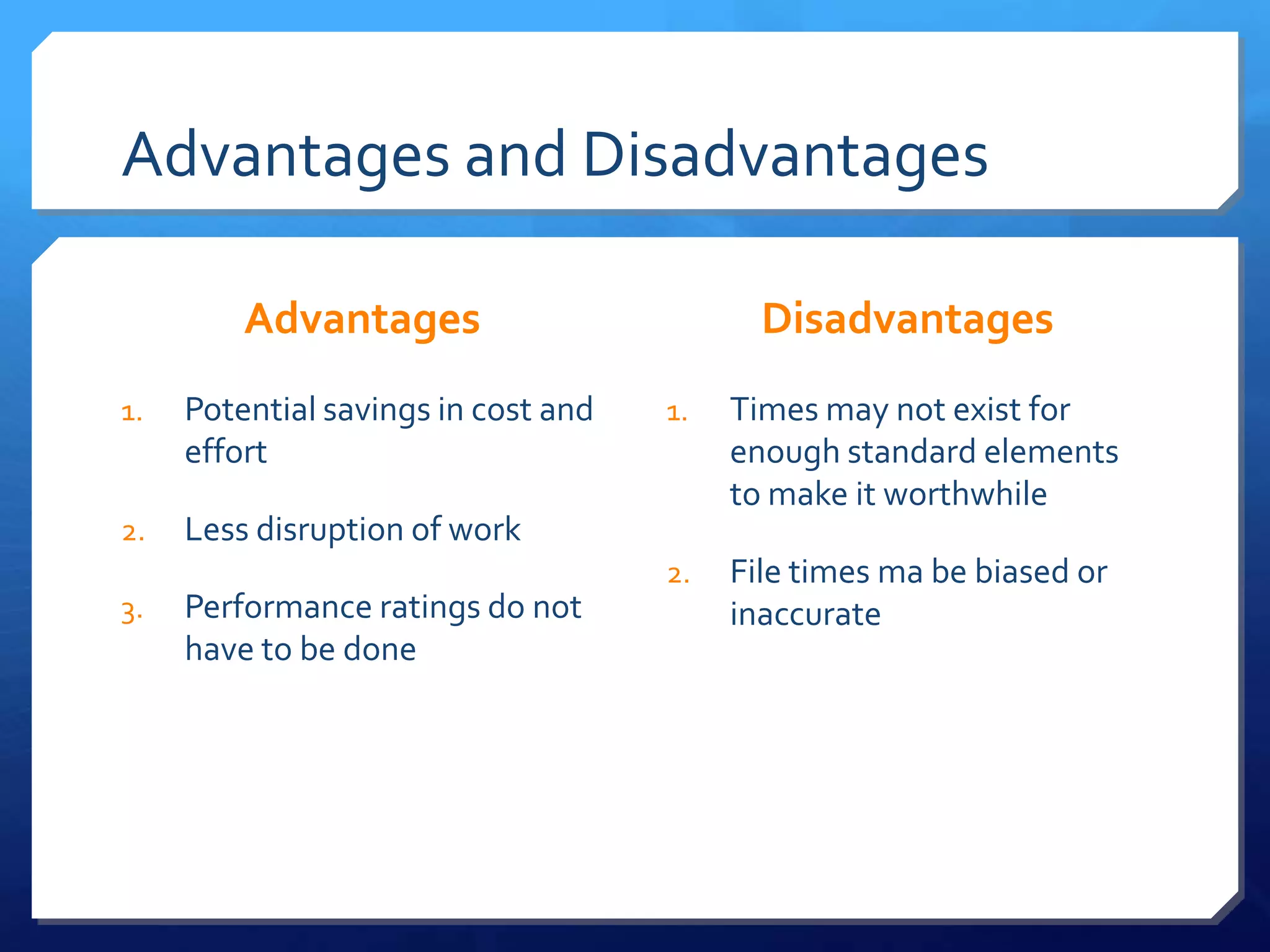

3. It also covers topics like motivation, teams, methods analysis, motion study, work measurement, and developing time standards to evaluate job performance.