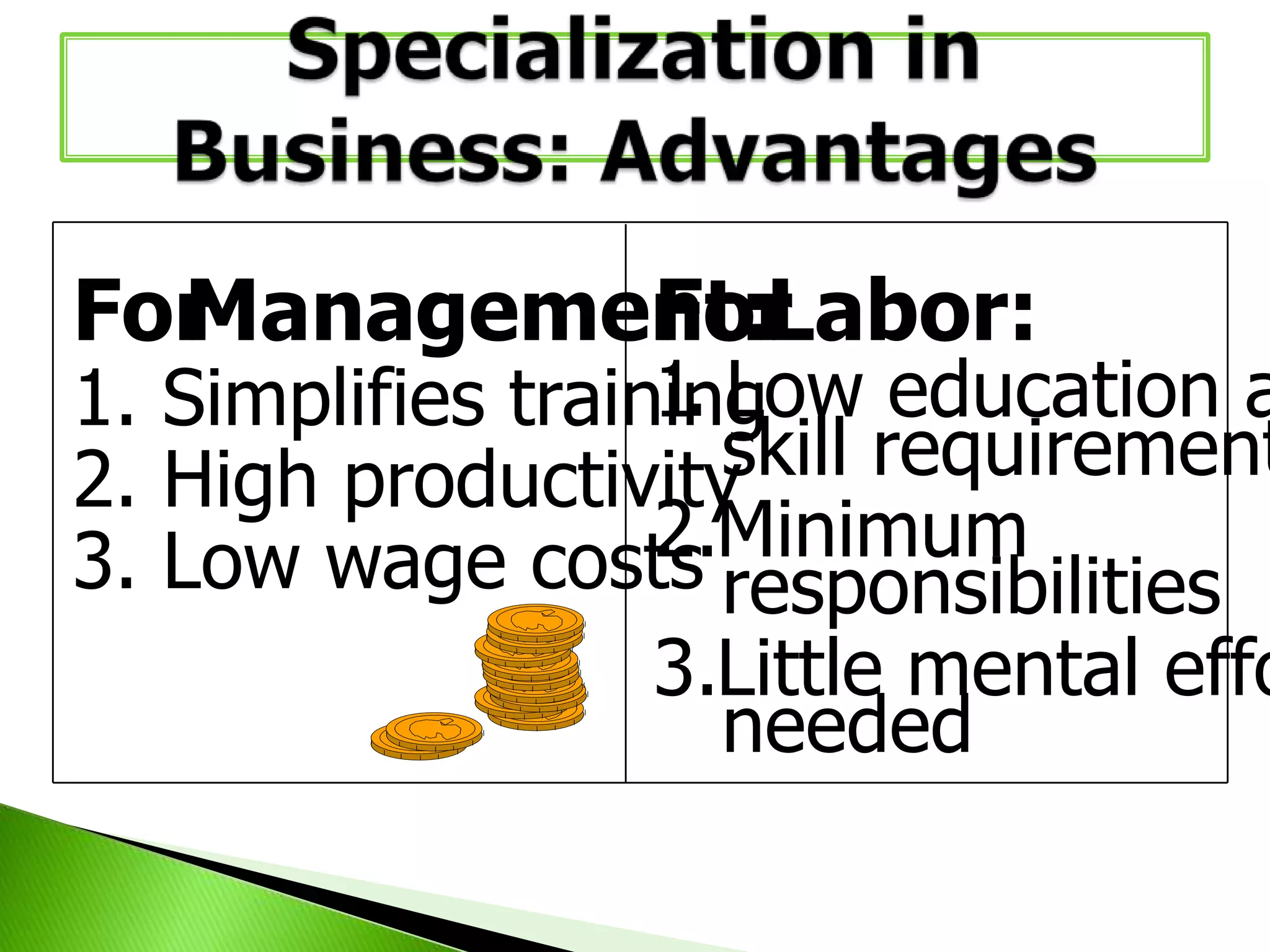

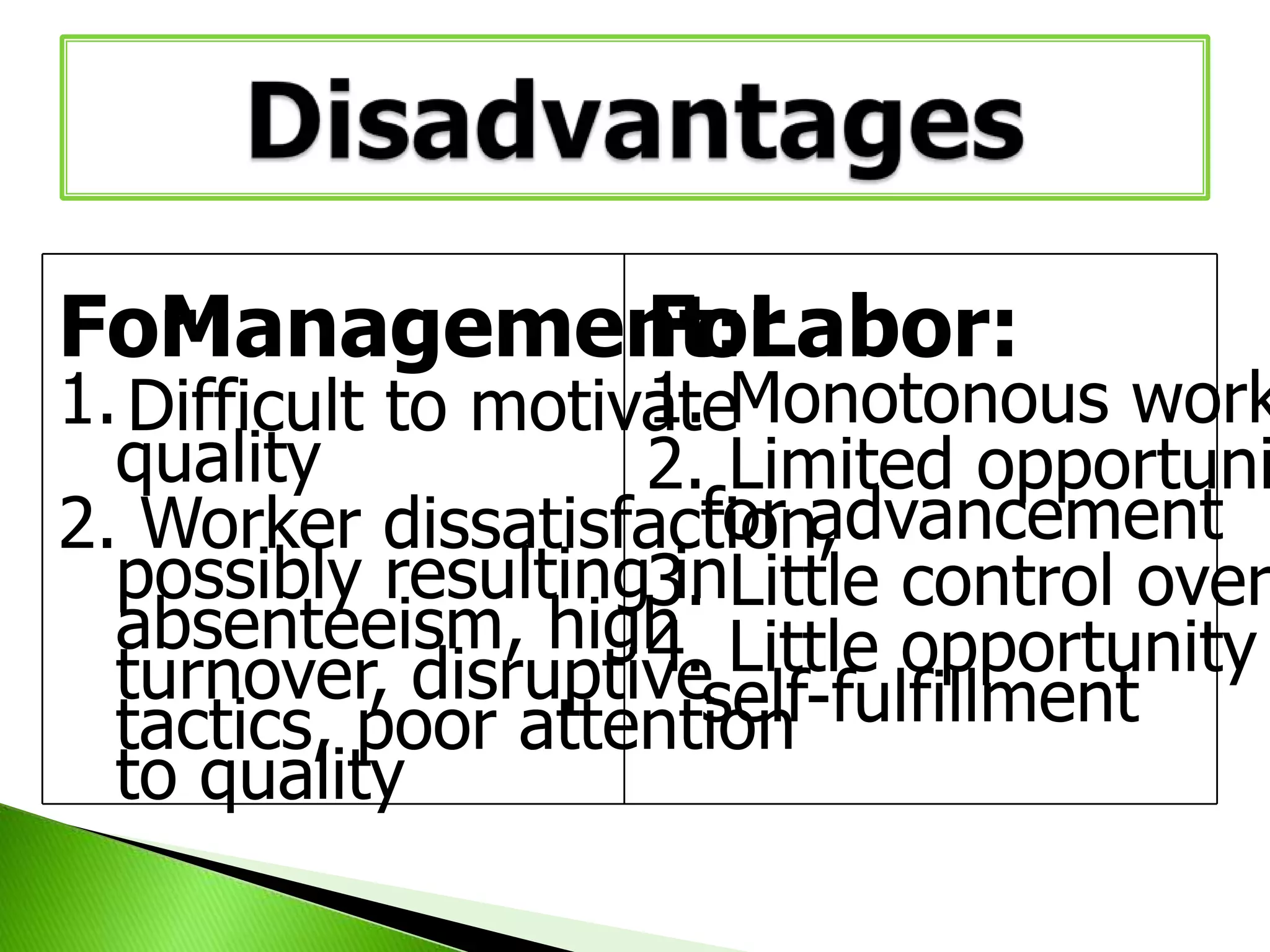

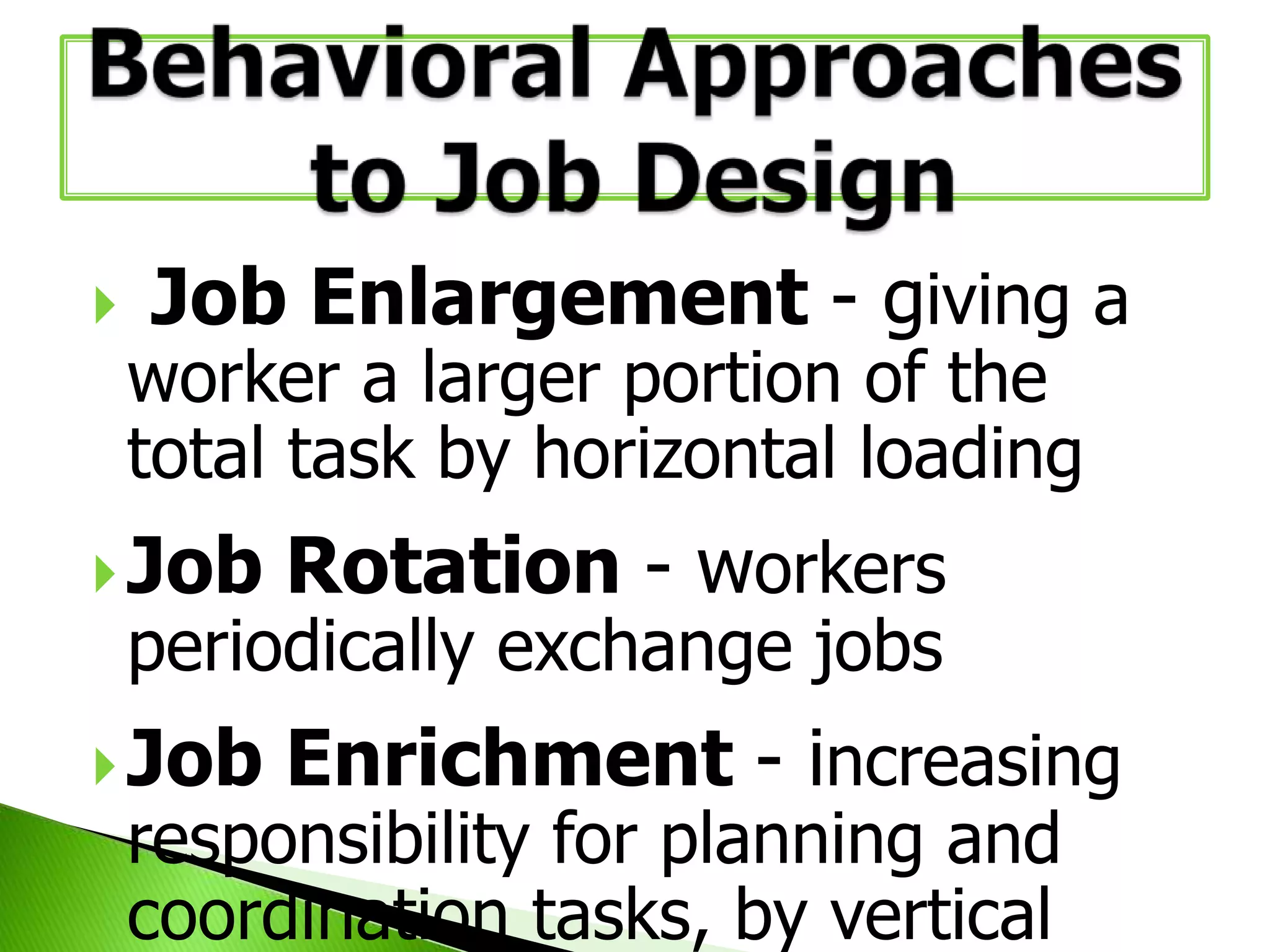

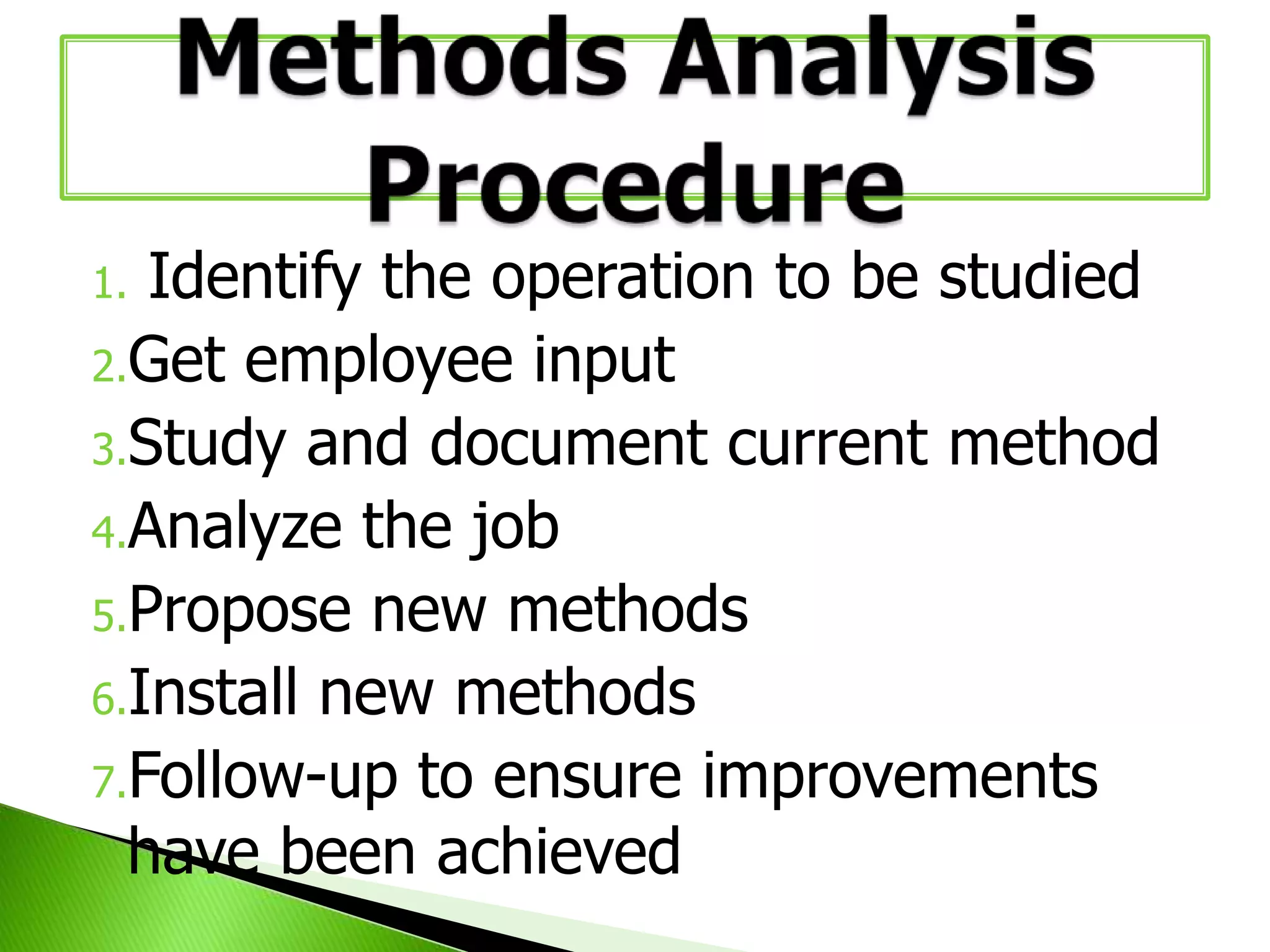

This document discusses various topics related to job design and work measurement including: defining the content and tasks of a job; ensuring job design is consistent with organizational goals and understood by management and employees; different approaches to job design like specialization, job enlargement and rotation, and job enrichment; analyzing methods of performing jobs; studying worker motions to improve efficiency; and measuring work to set performance standards. It also covers work environment factors and different compensation systems like time-based pay and incentive plans.