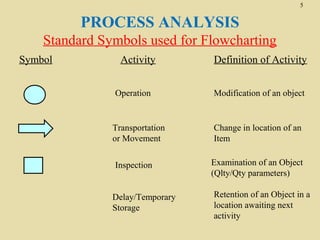

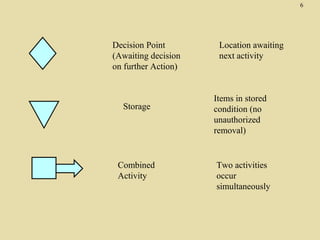

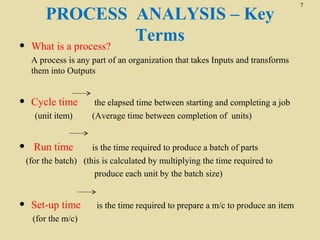

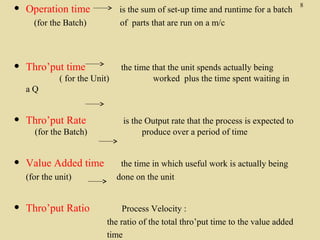

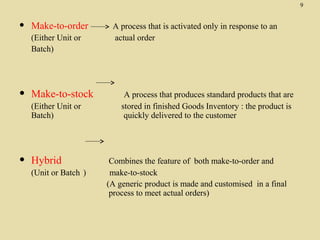

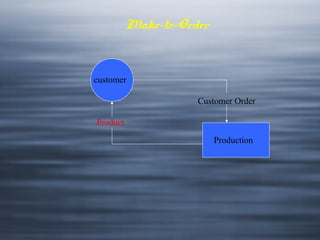

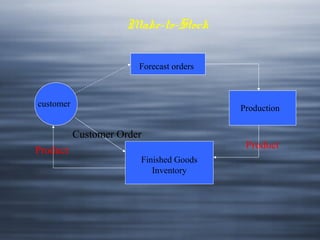

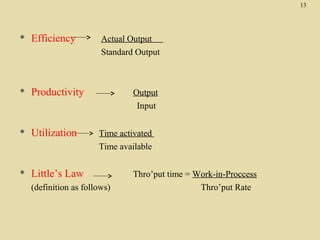

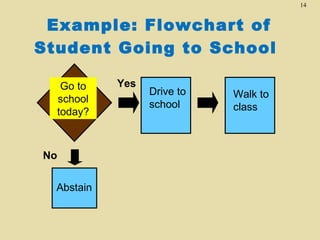

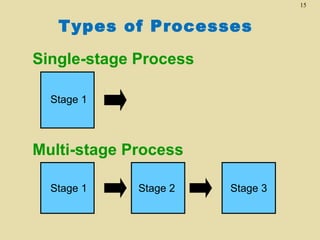

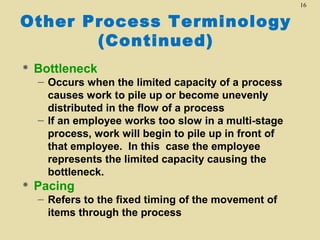

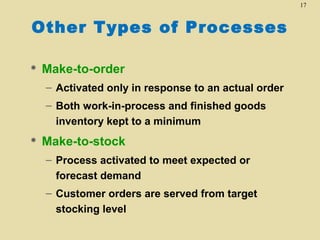

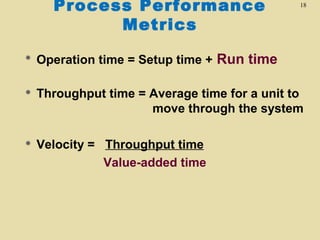

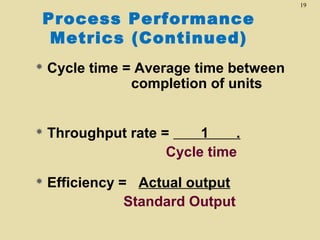

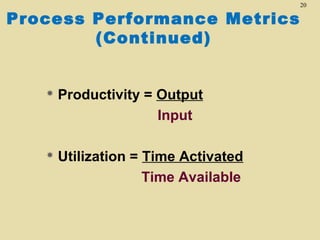

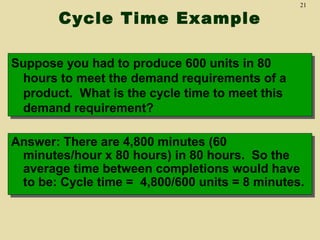

This document discusses process analysis. It begins with objectives like process analysis, flowcharting, types of processes, and performance metrics. It then defines key terms like process, cycle time, and utilization. It describes standard flowchart symbols and types of processes like make-to-order, make-to-stock, and hybrid. Finally, it discusses performance metrics such as operation time, throughput time, velocity, and productivity and provides examples to illustrate concepts.

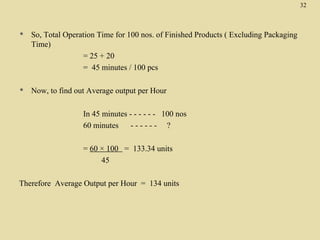

![31

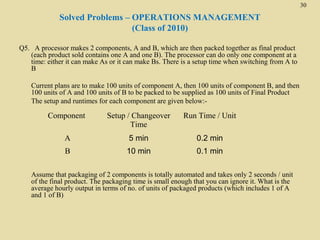

Answer. In order to make final goods, we have to assemble both component A and

component B.

So, let us find out the final operation time for both the components :

Component A

Operation Time = Setuptime + Runtime (for batch)

= 5 + [ (0.2 × 100)]

= 25 minutes

Component B

Operation Time = Setuptime + Runtime (for batch)

= 10 + [ (0.1 × 100)]

= 20 minutes](https://image.slidesharecdn.com/ch5-processanalysis-131122013048-phpapp02/85/Ch5-process-analysis-31-320.jpg)