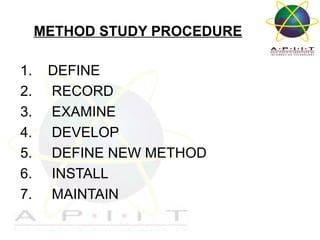

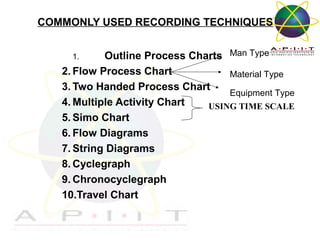

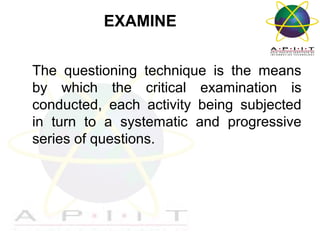

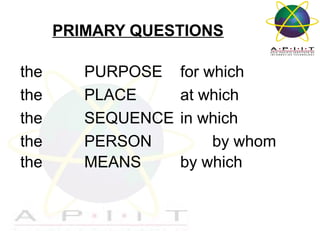

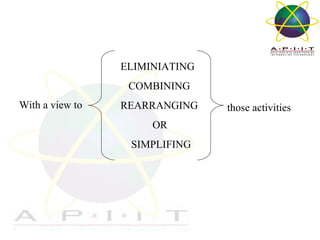

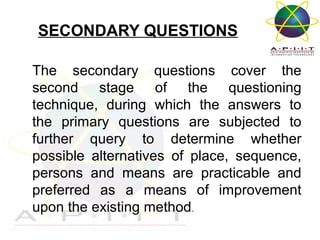

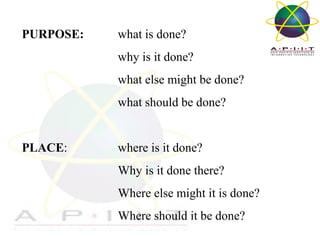

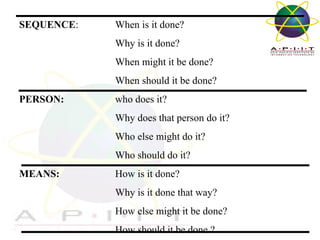

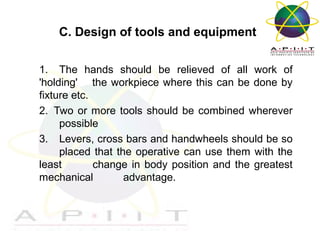

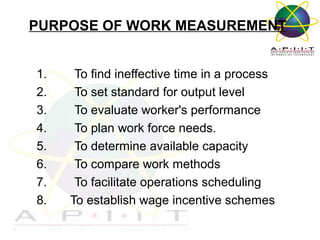

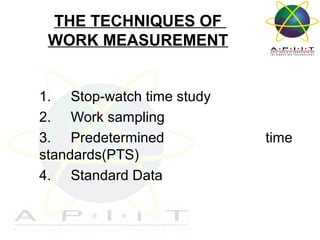

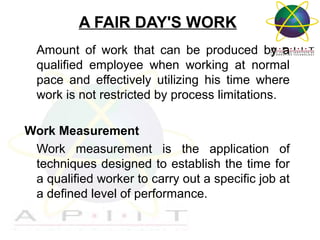

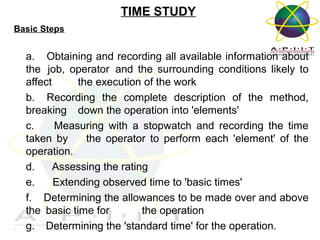

Method study is the systematic recording and examination of work processes to develop more efficient methods. Its objectives include improving processes, equipment design, layout, resource use, safety, and work environment. The method study procedure involves defining the current method, recording it, examining it for improvements, developing new methods, installing them, and maintaining them. Common recording techniques include process charts, diagrams, and time measurement tools. Method study aims to reduce unnecessary motions and optimize work arrangements, tools, and equipment usage according to principles of motion economy. It provides the basis for setting performance standards and incentives.