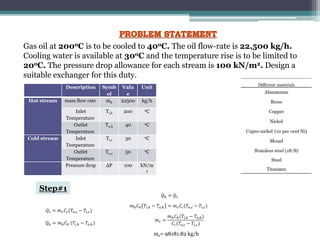

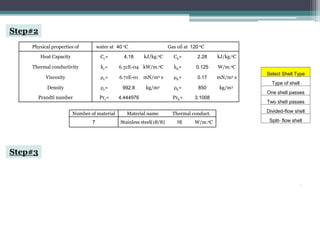

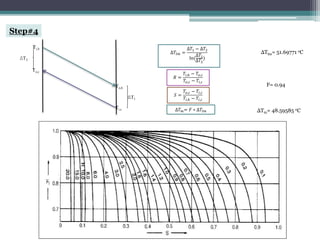

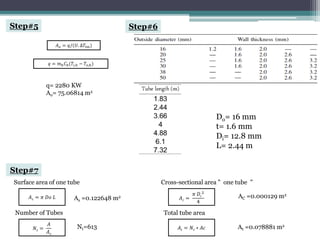

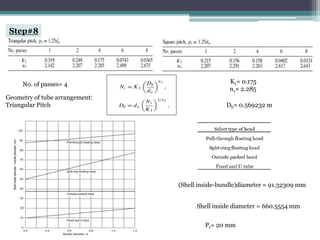

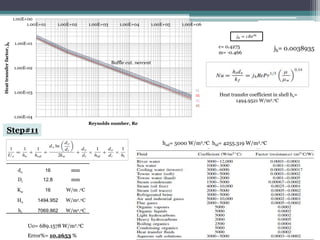

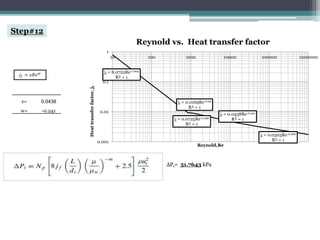

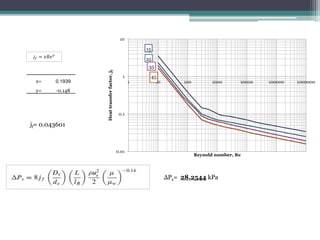

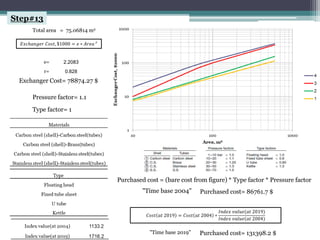

This document describes the design of a shell and tube heat exchanger. Gas oil at 200°C needs to be cooled to 40°C using cooling water available at 30°C, with the water's maximum temperature rise being 20°C. The design calculations are shown to size a heat exchanger for this duty, with a mass flow rate of 22,500 kg/h for the gas oil and 98,181 kg/h for the water. Key design parameters calculated include heat transfer area, number of tubes, tube arrangement, and pressure drops. The total cost of the designed exchanger is estimated to be around $131,398.