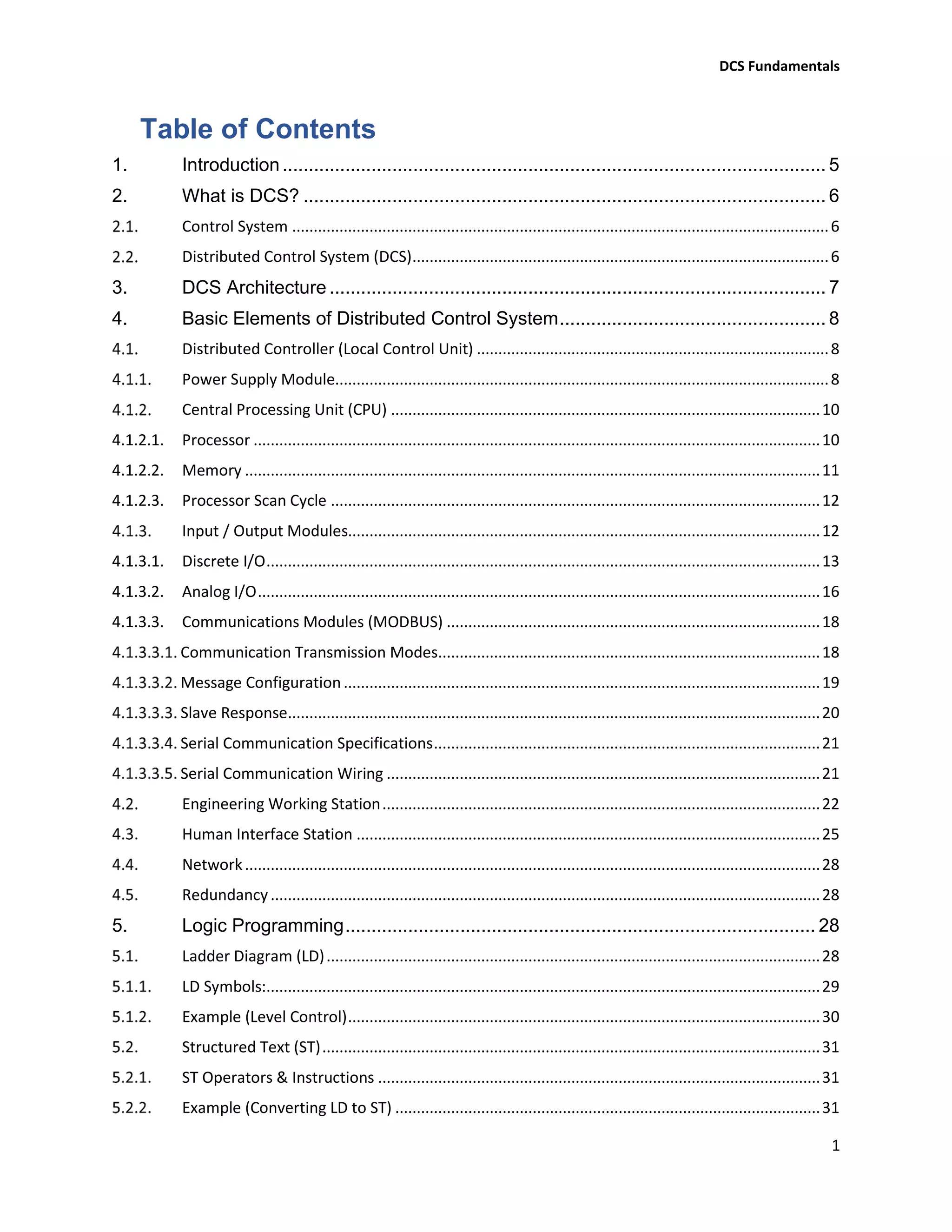

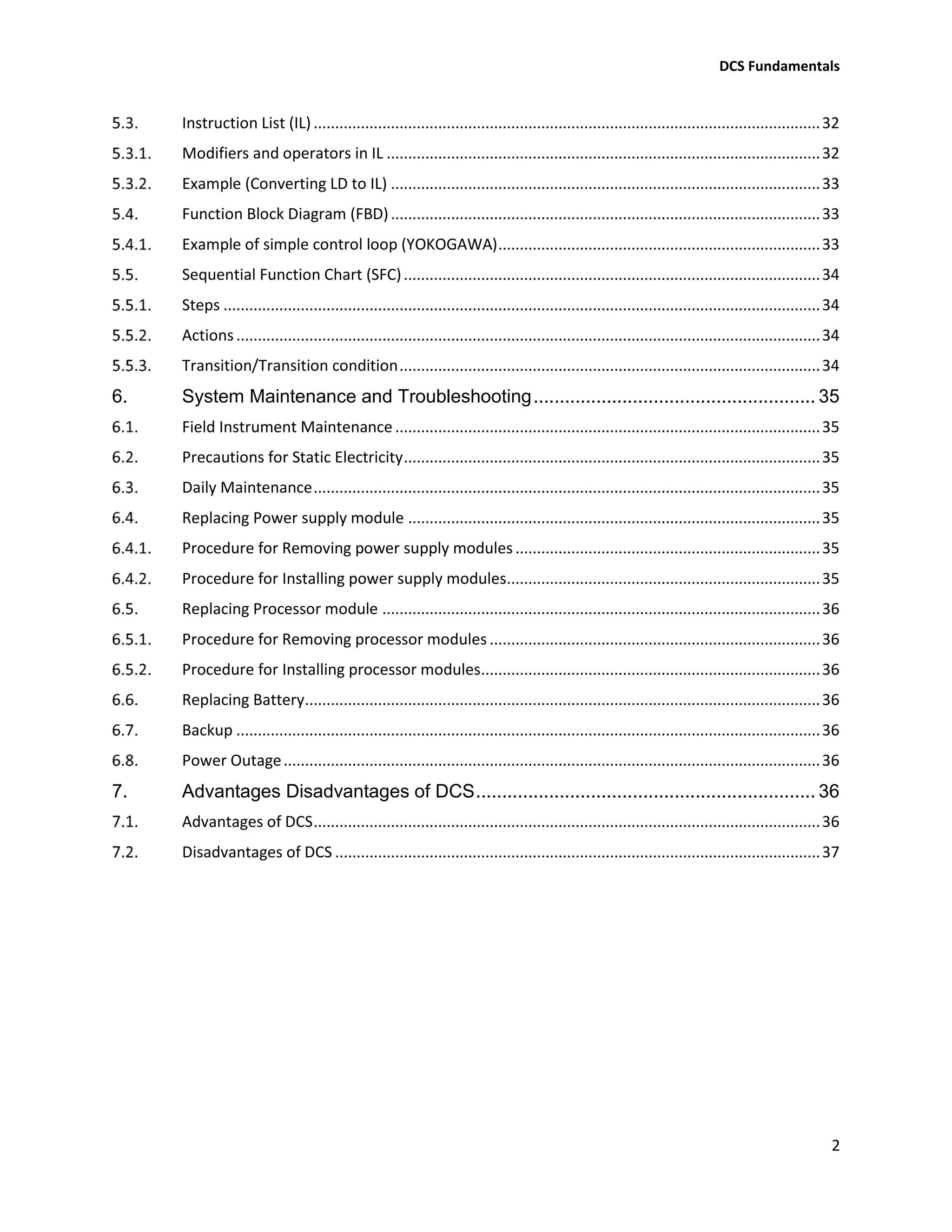

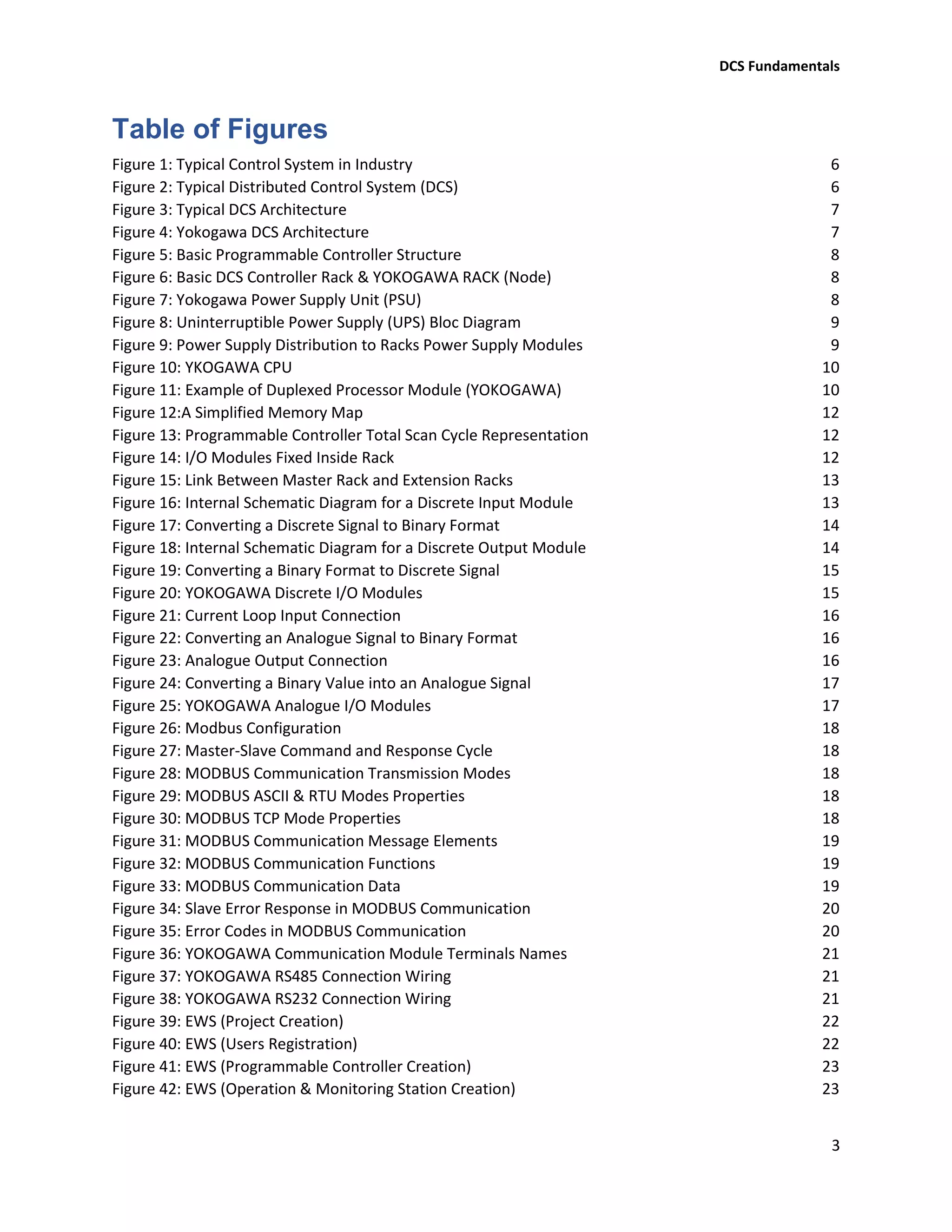

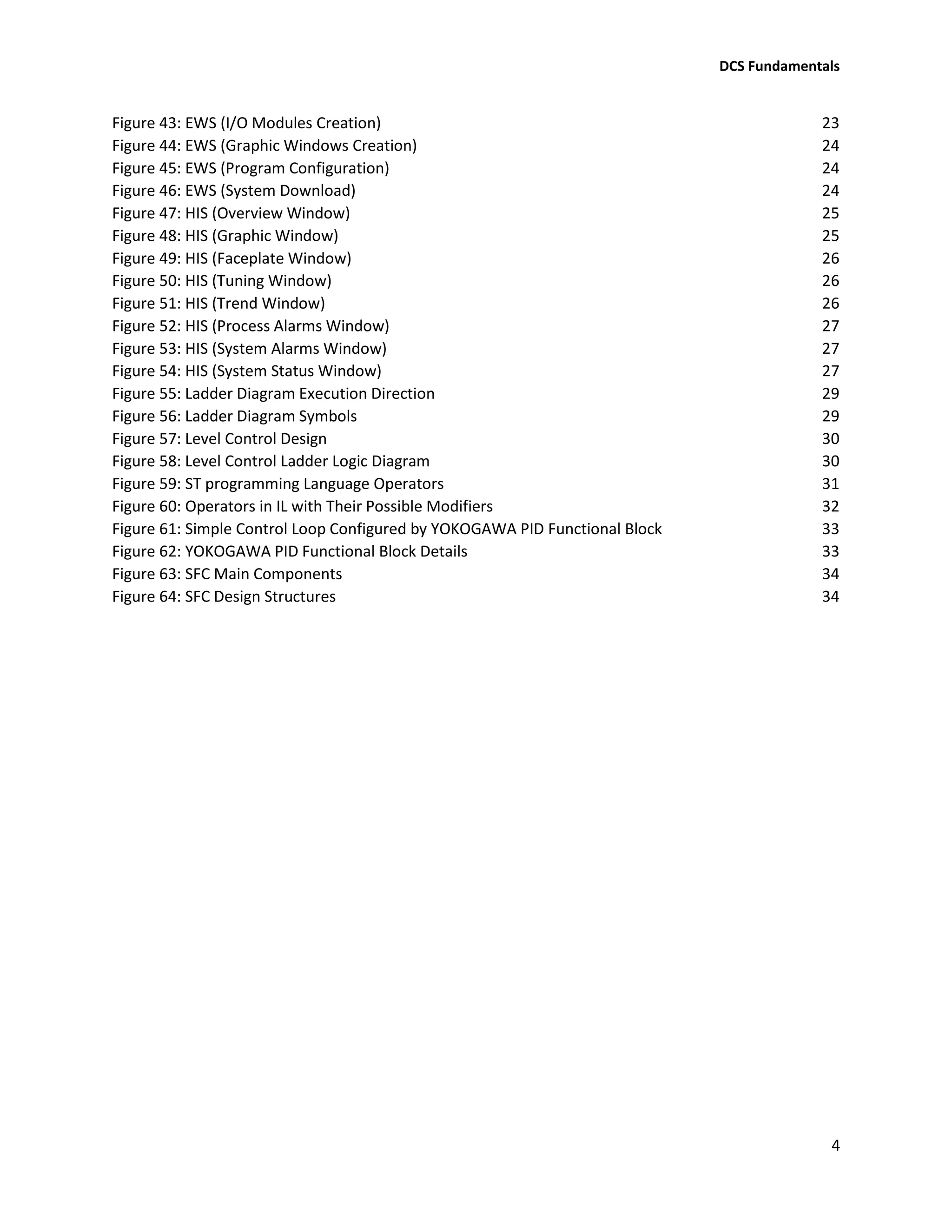

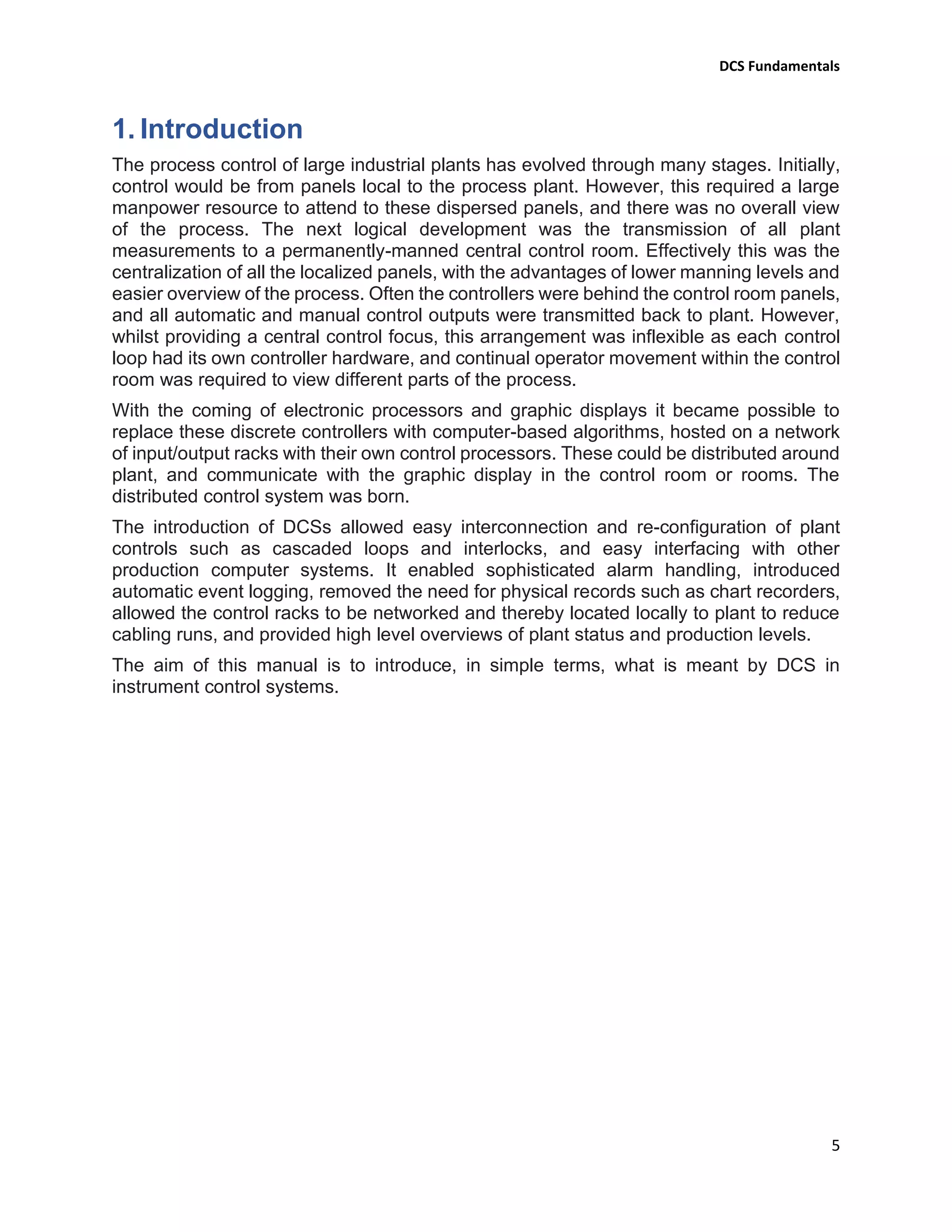

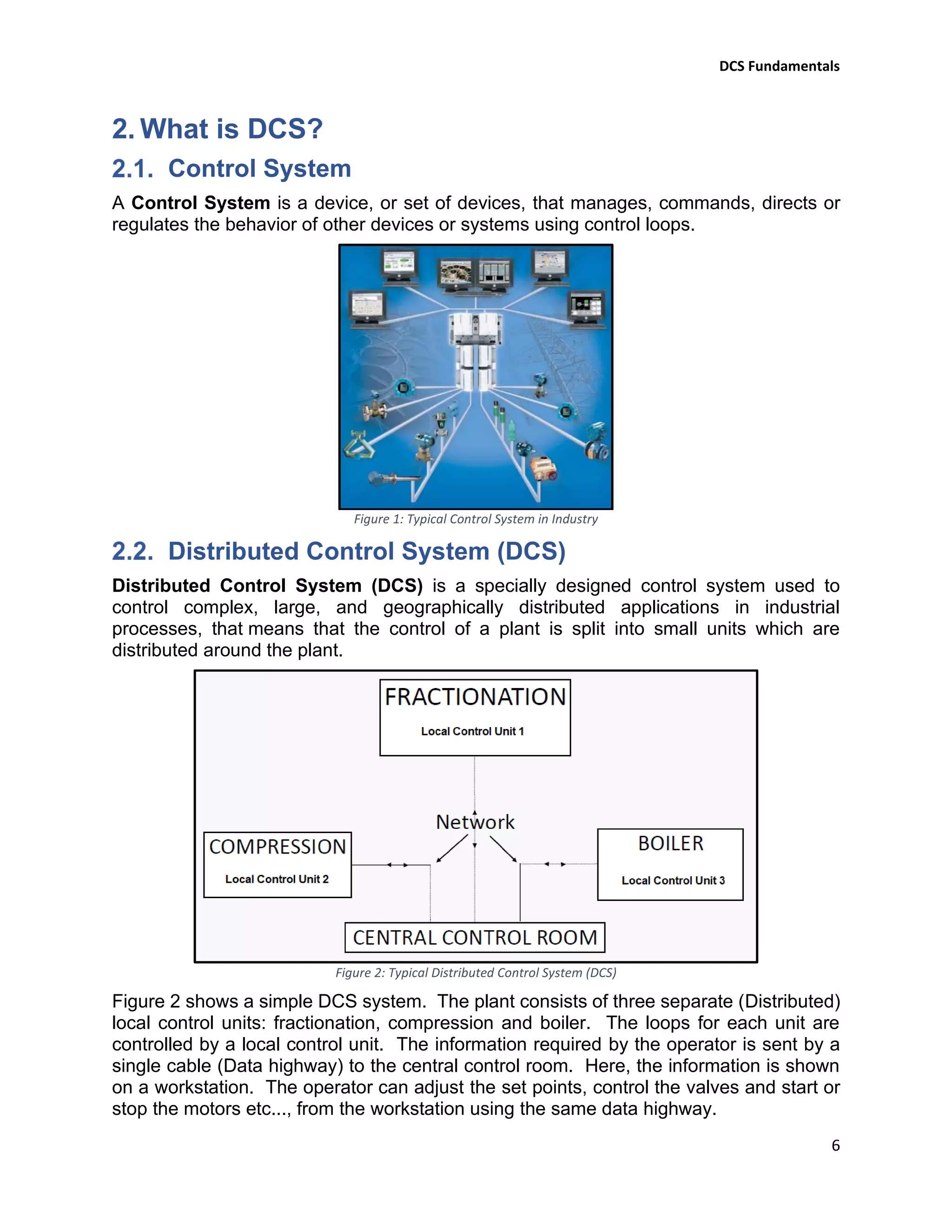

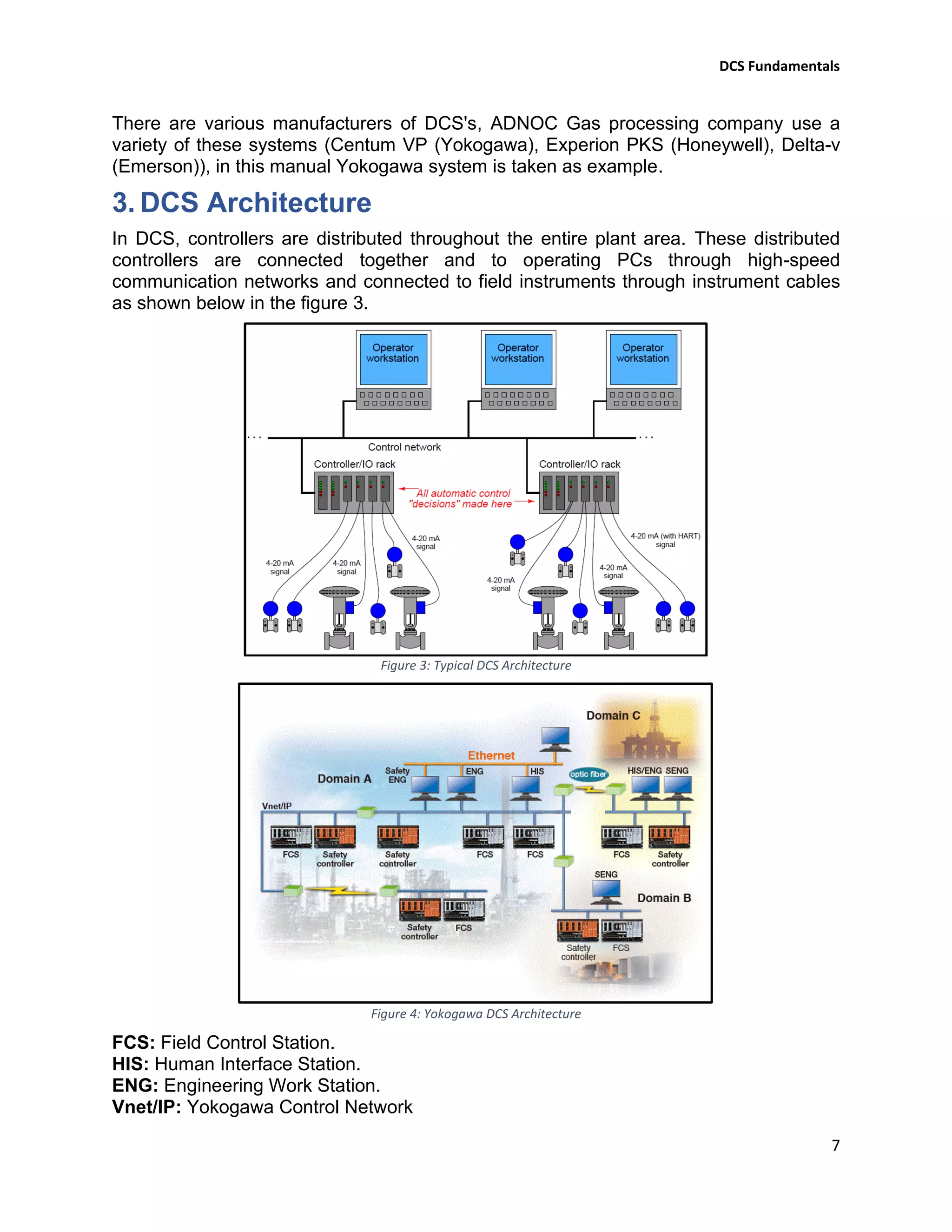

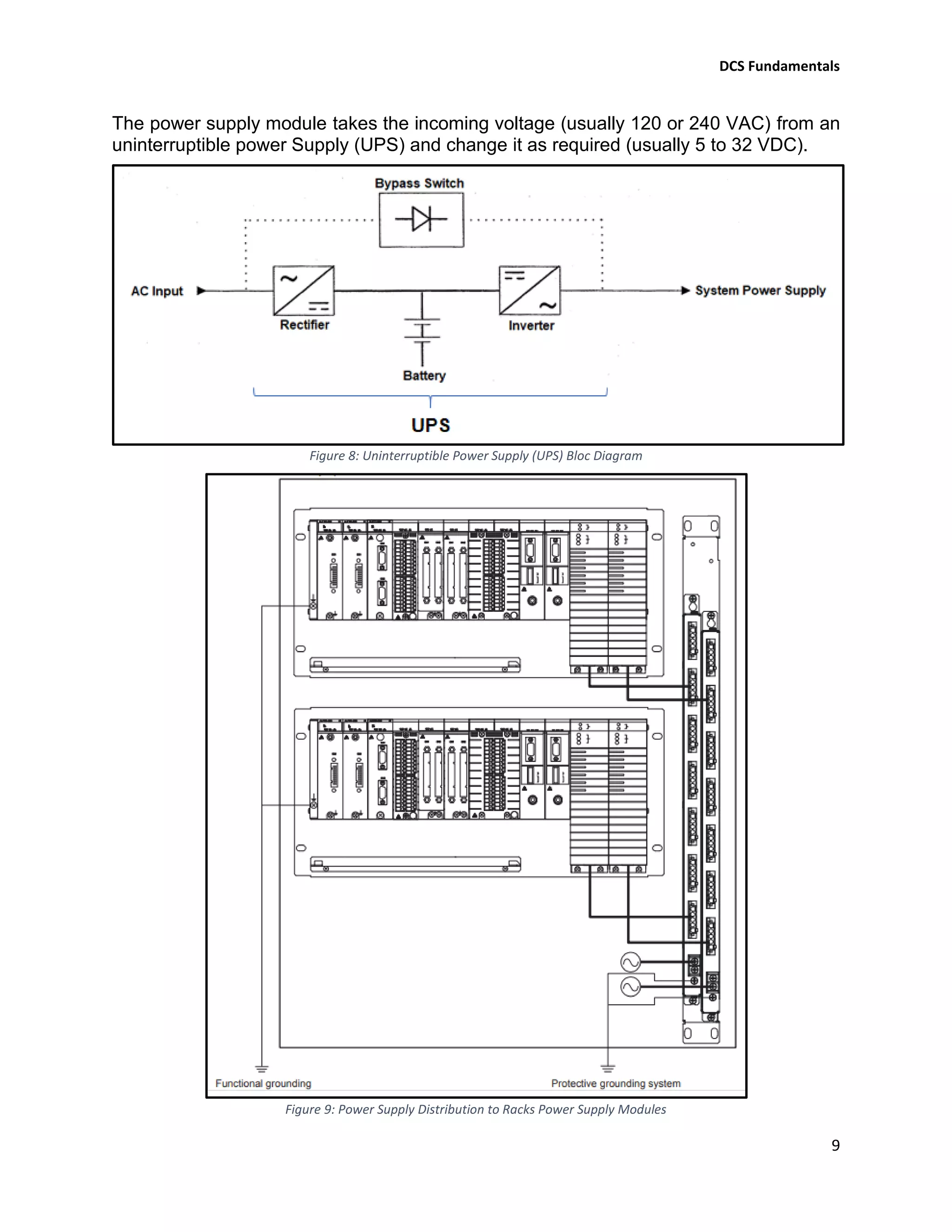

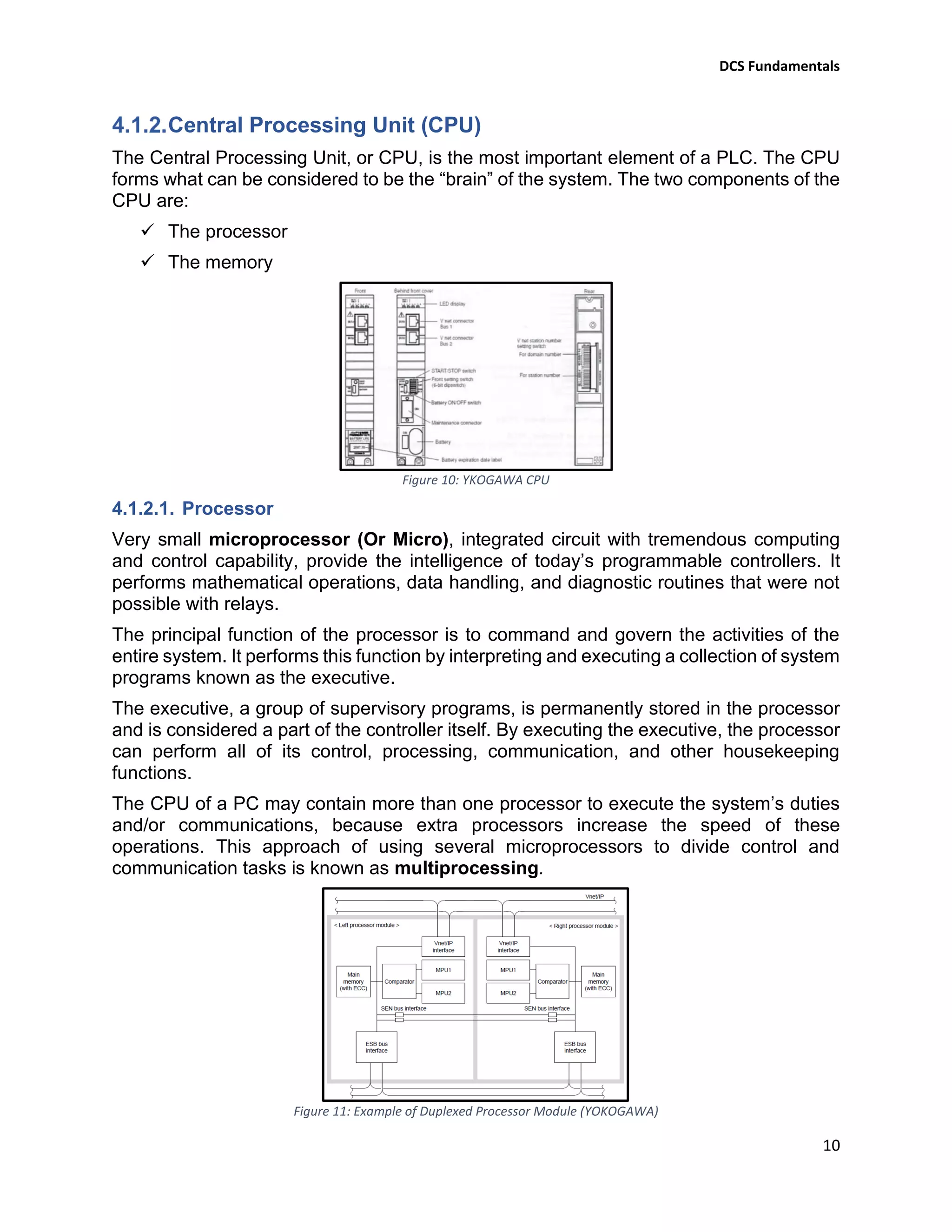

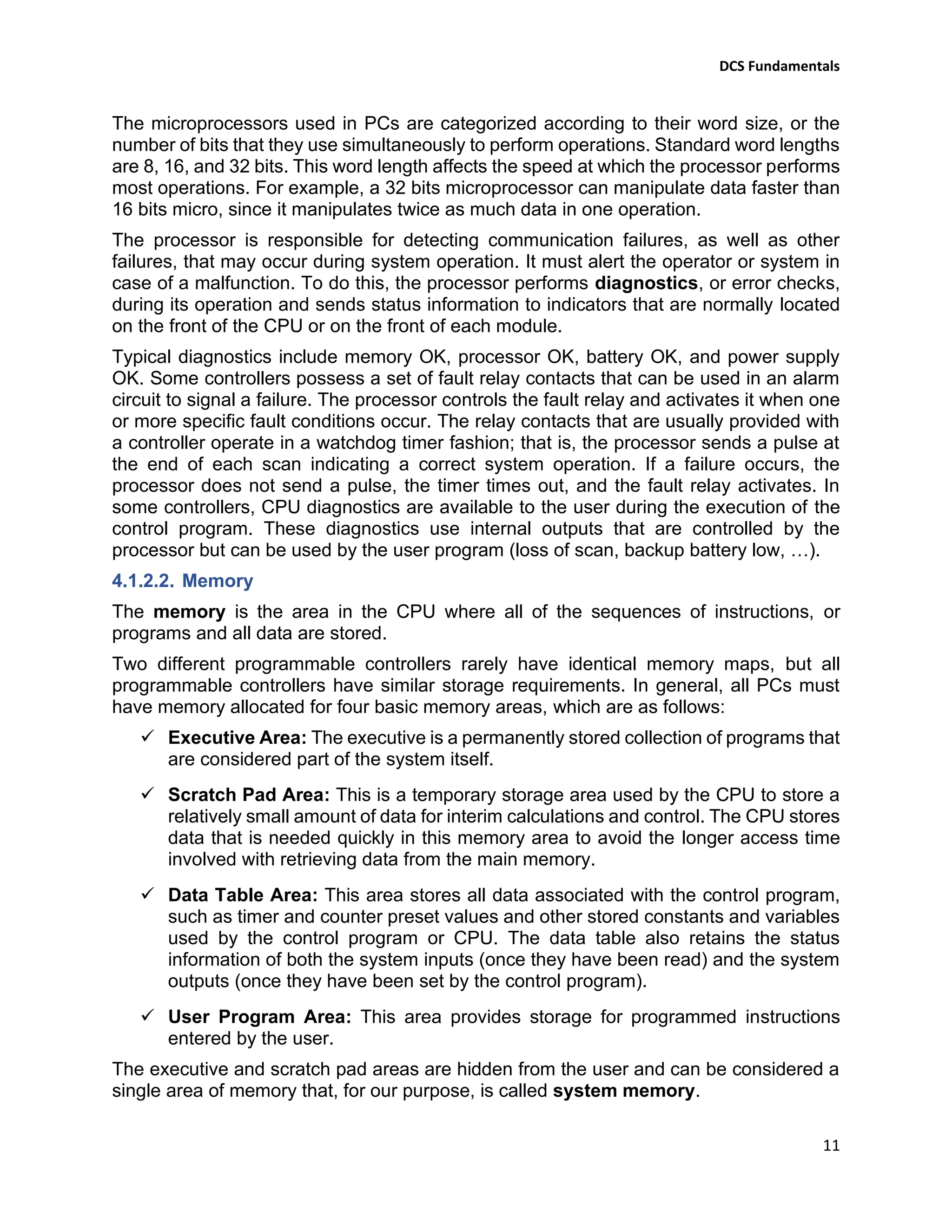

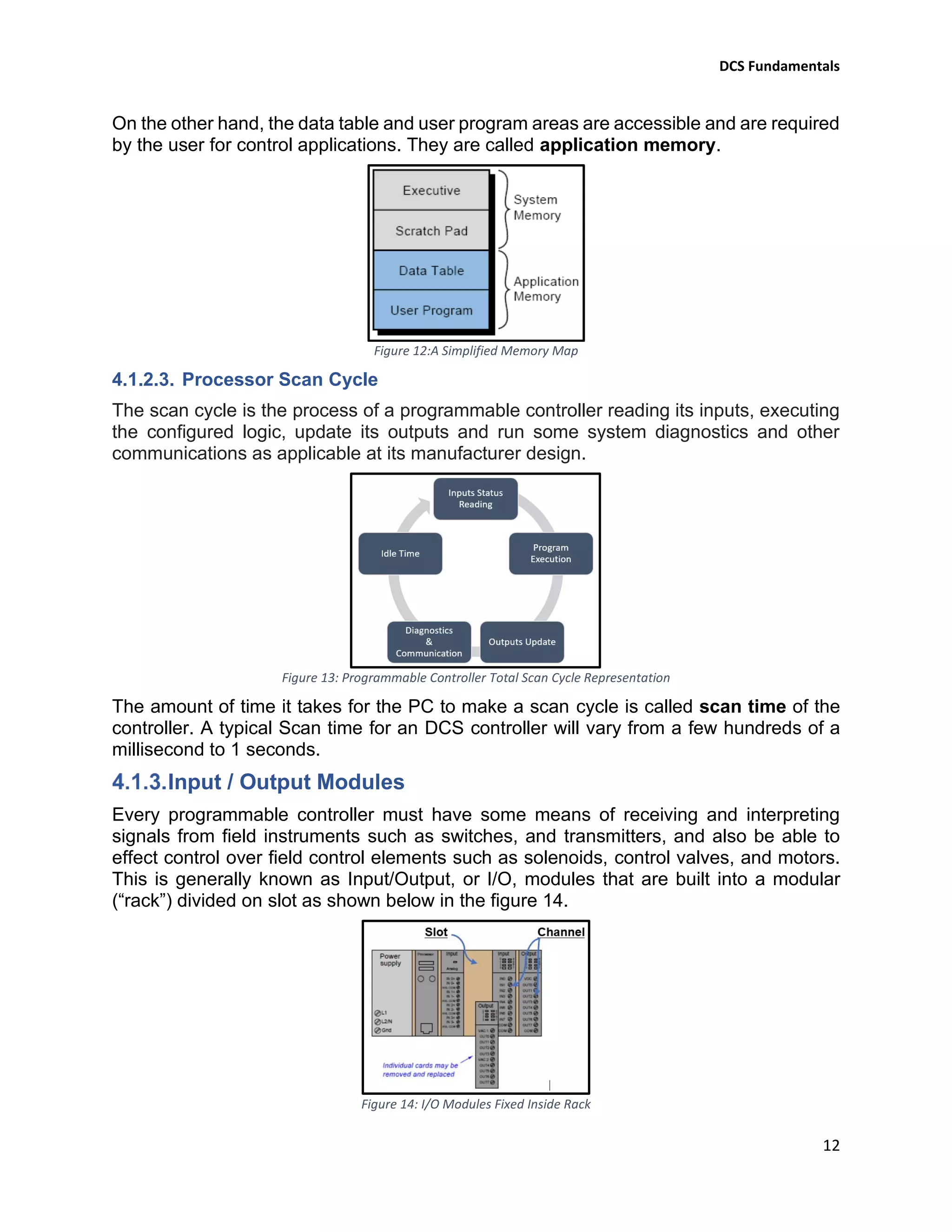

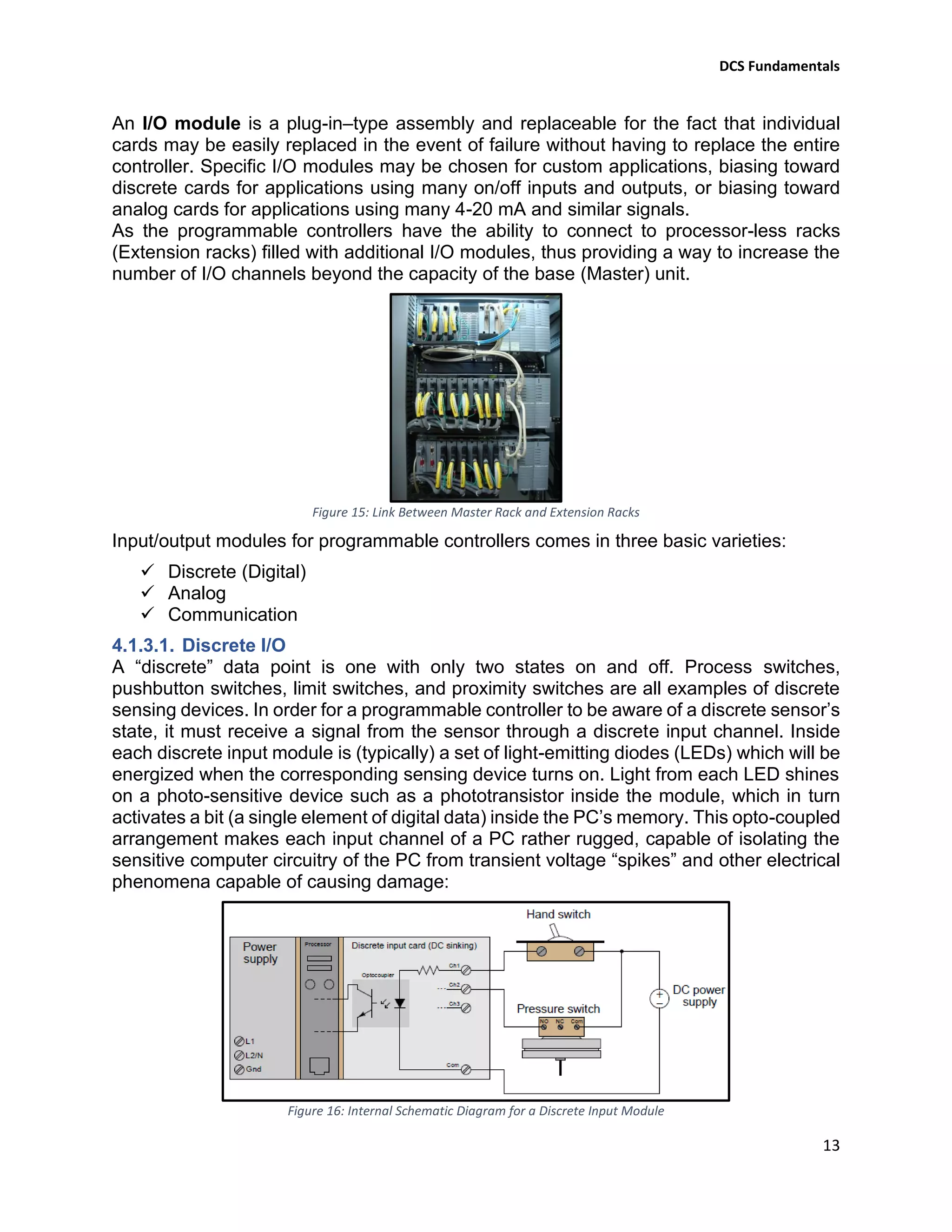

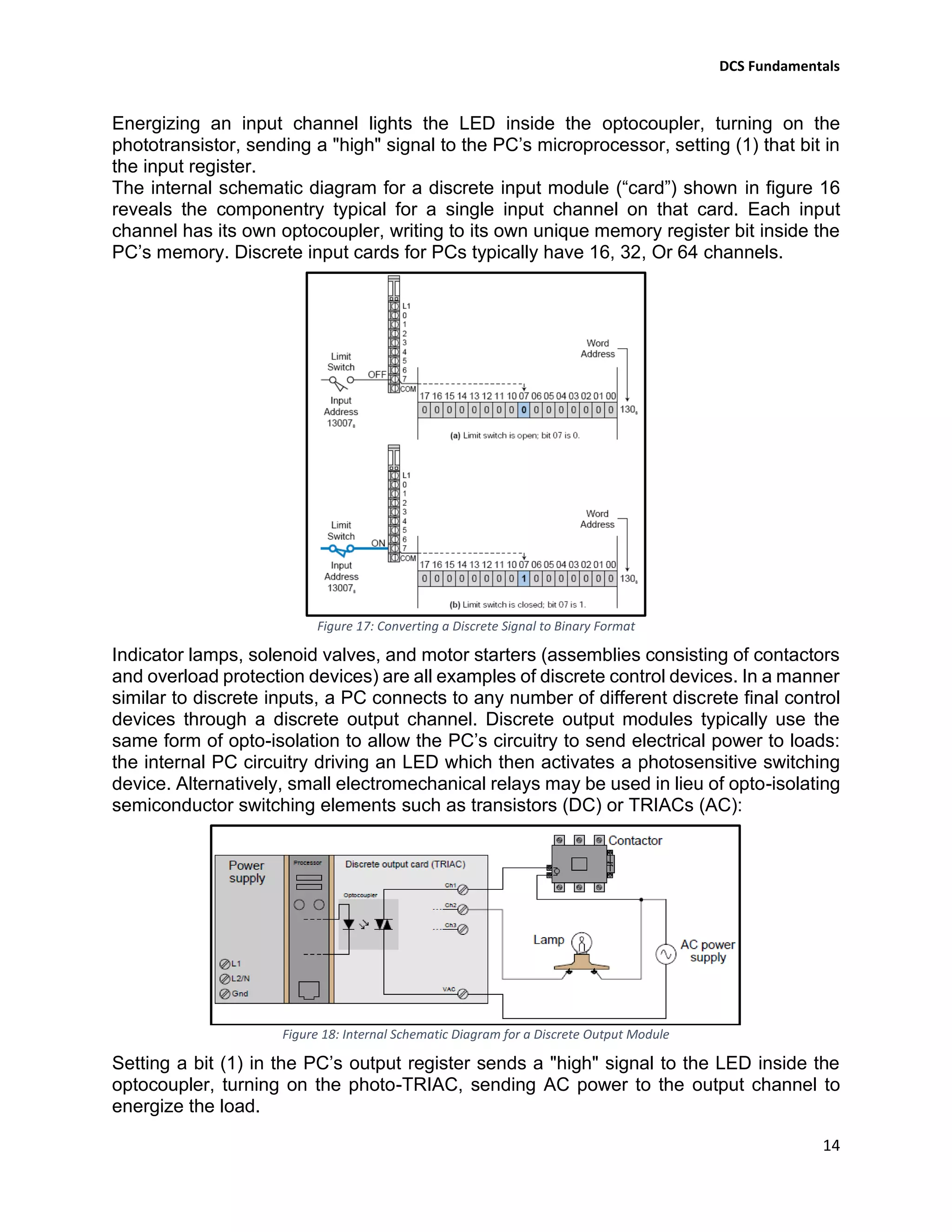

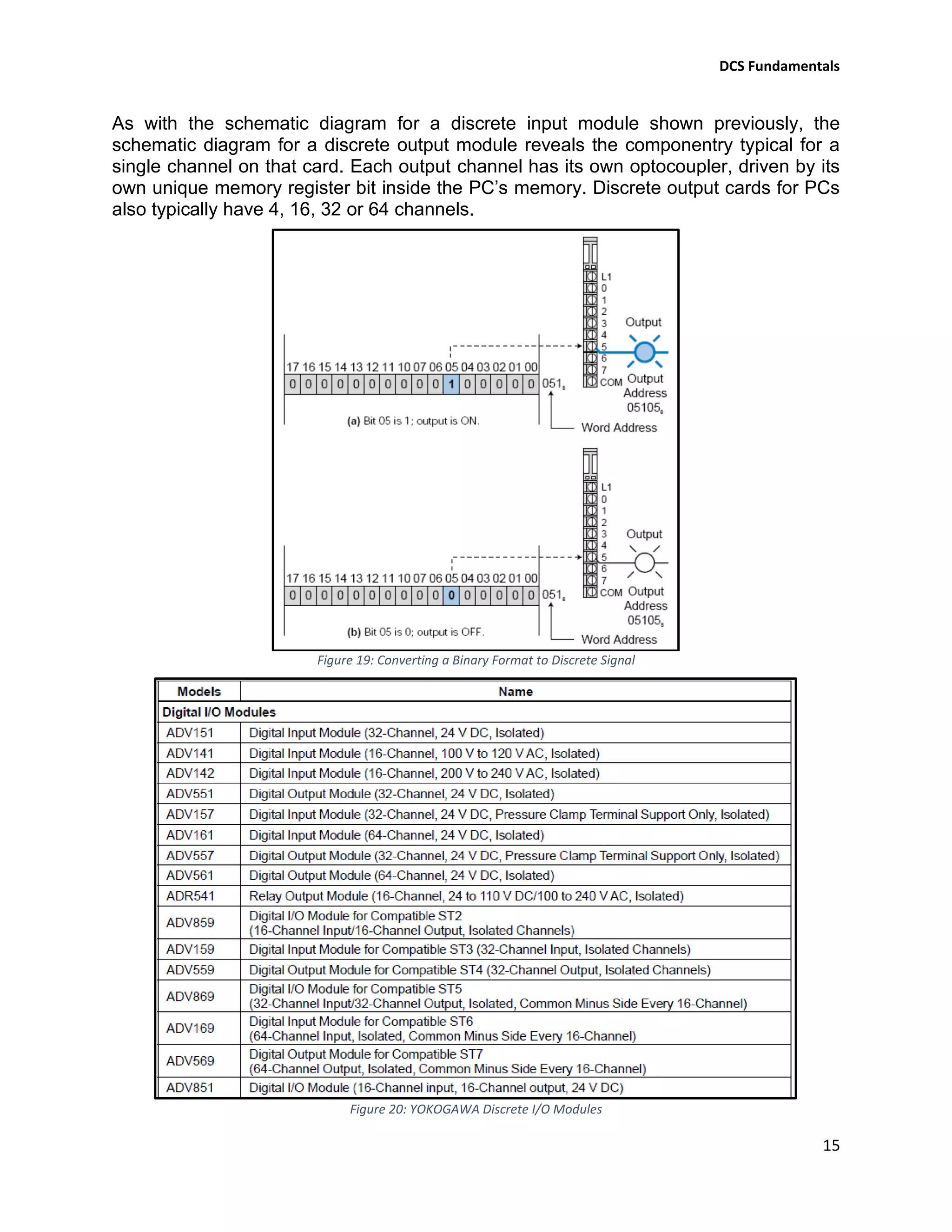

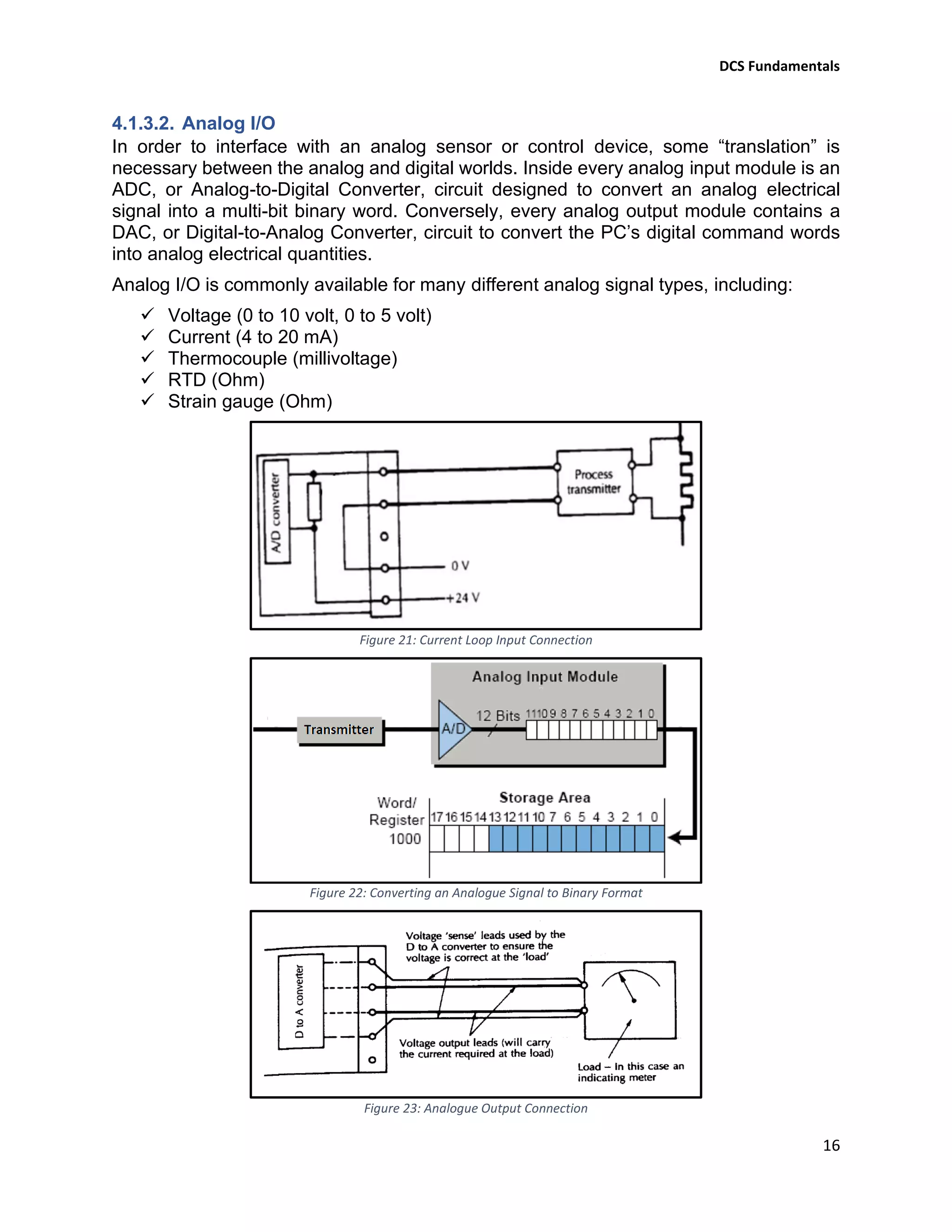

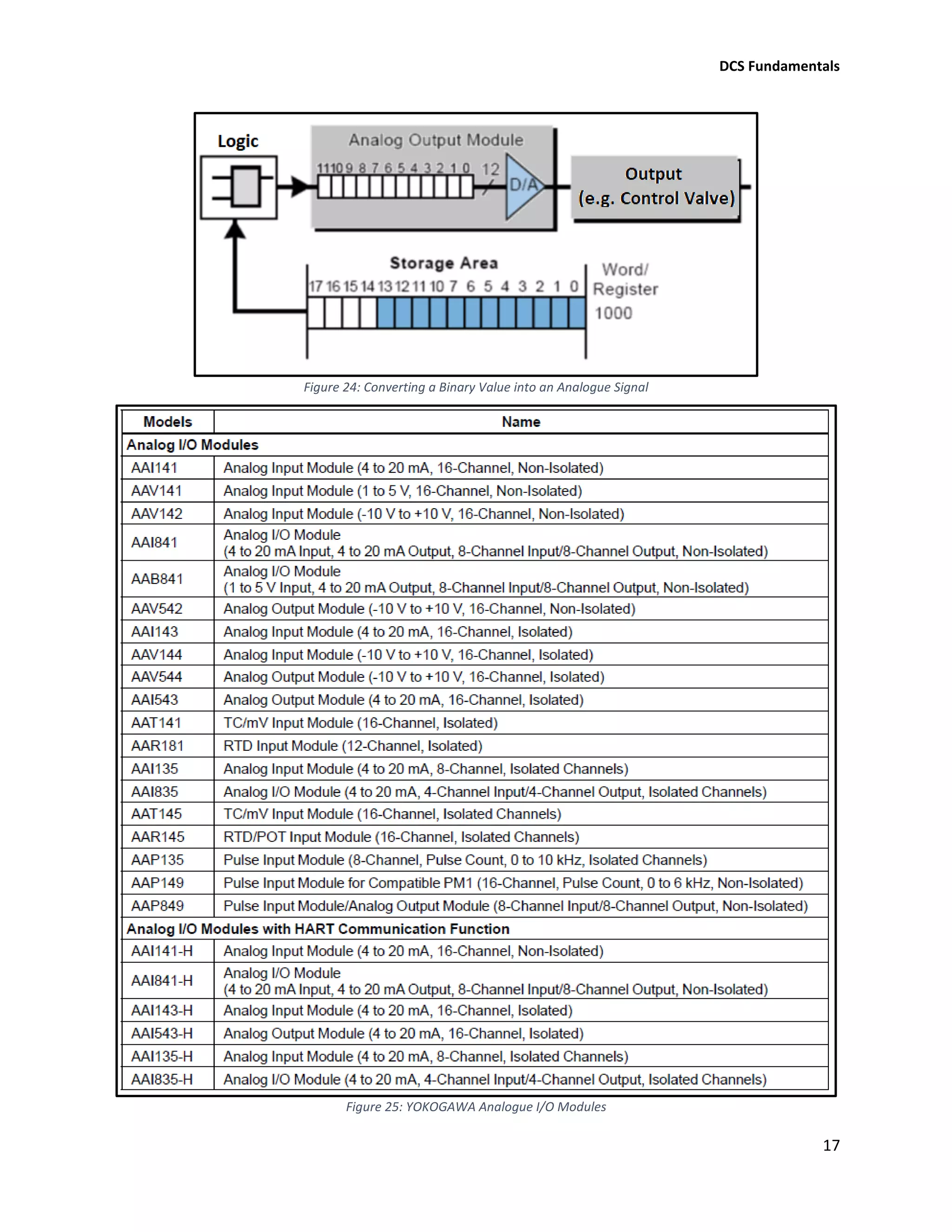

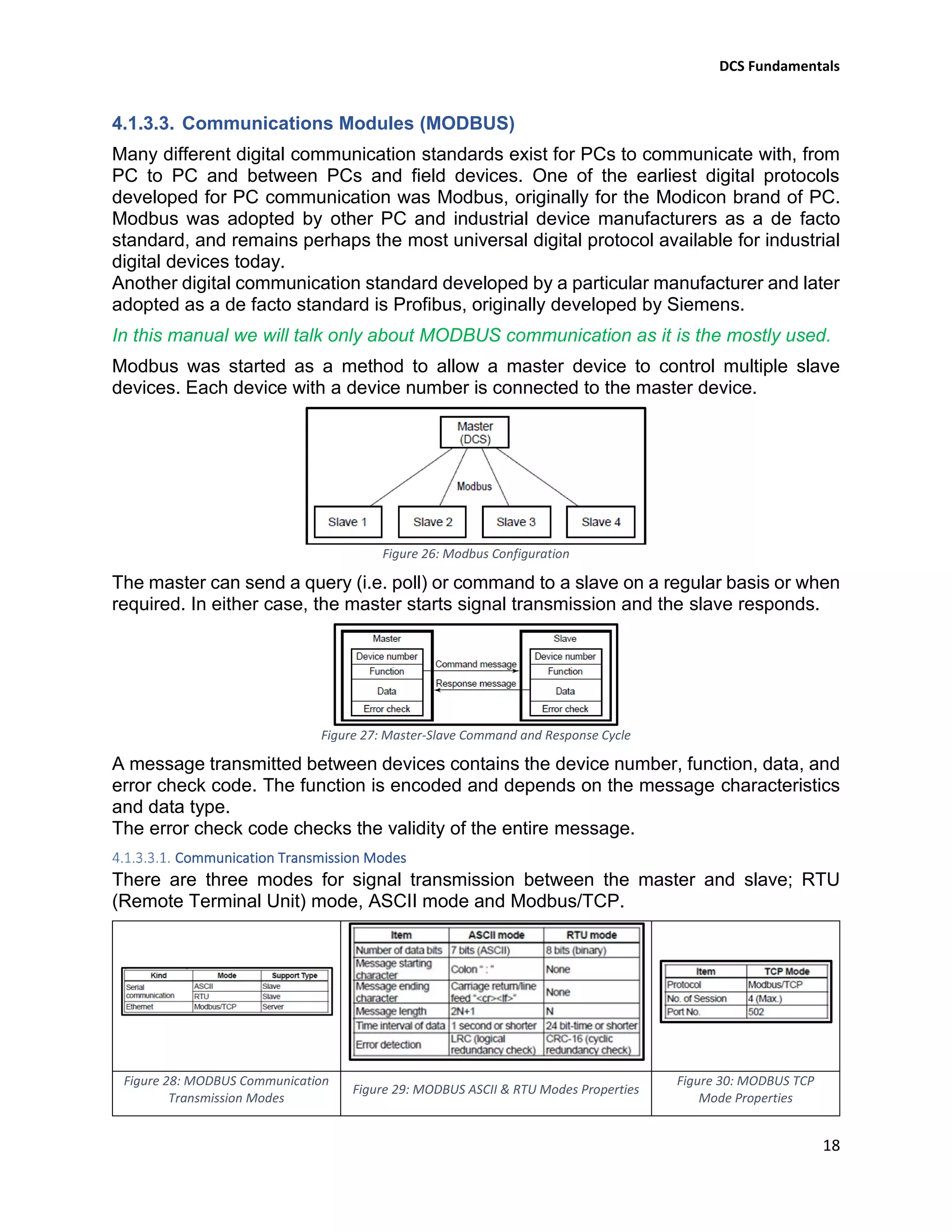

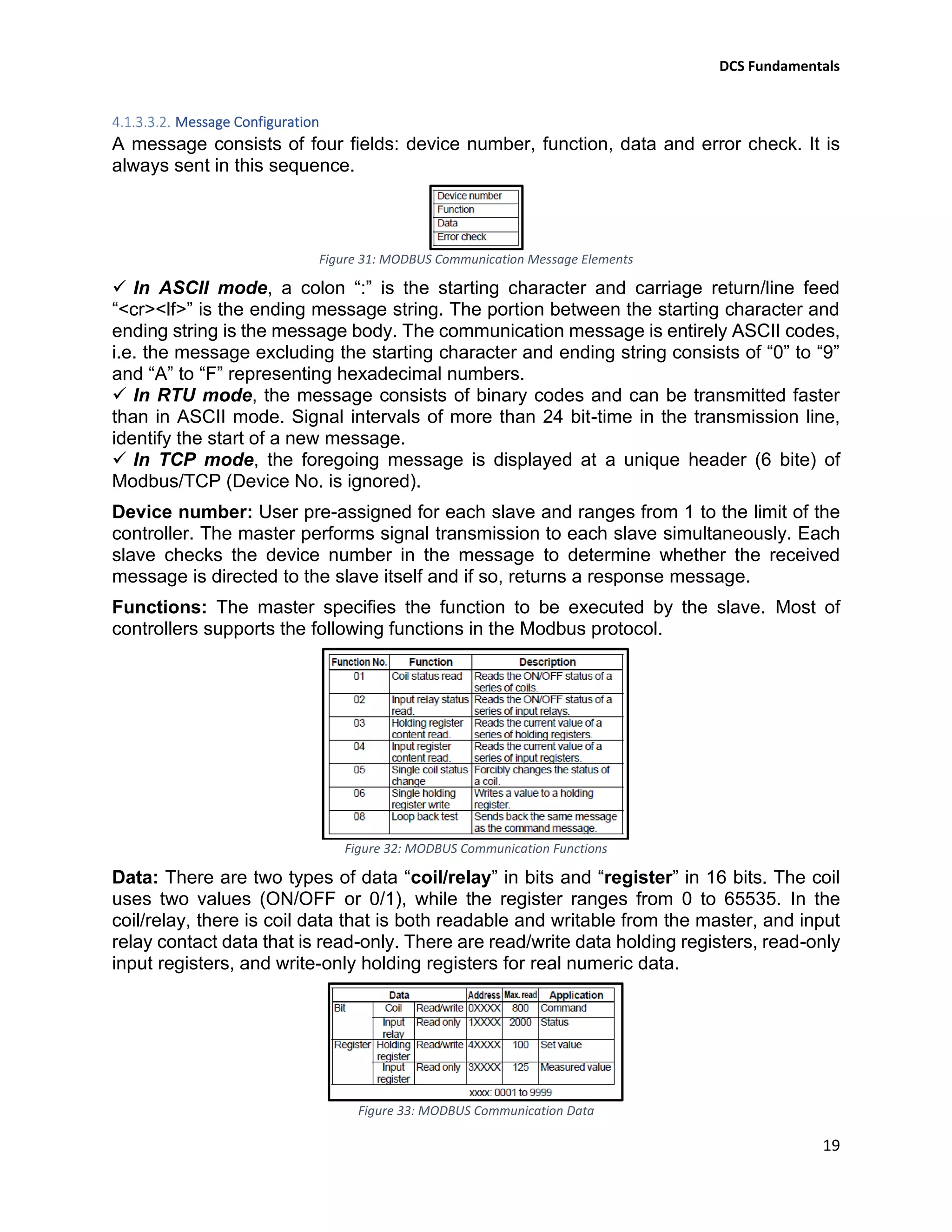

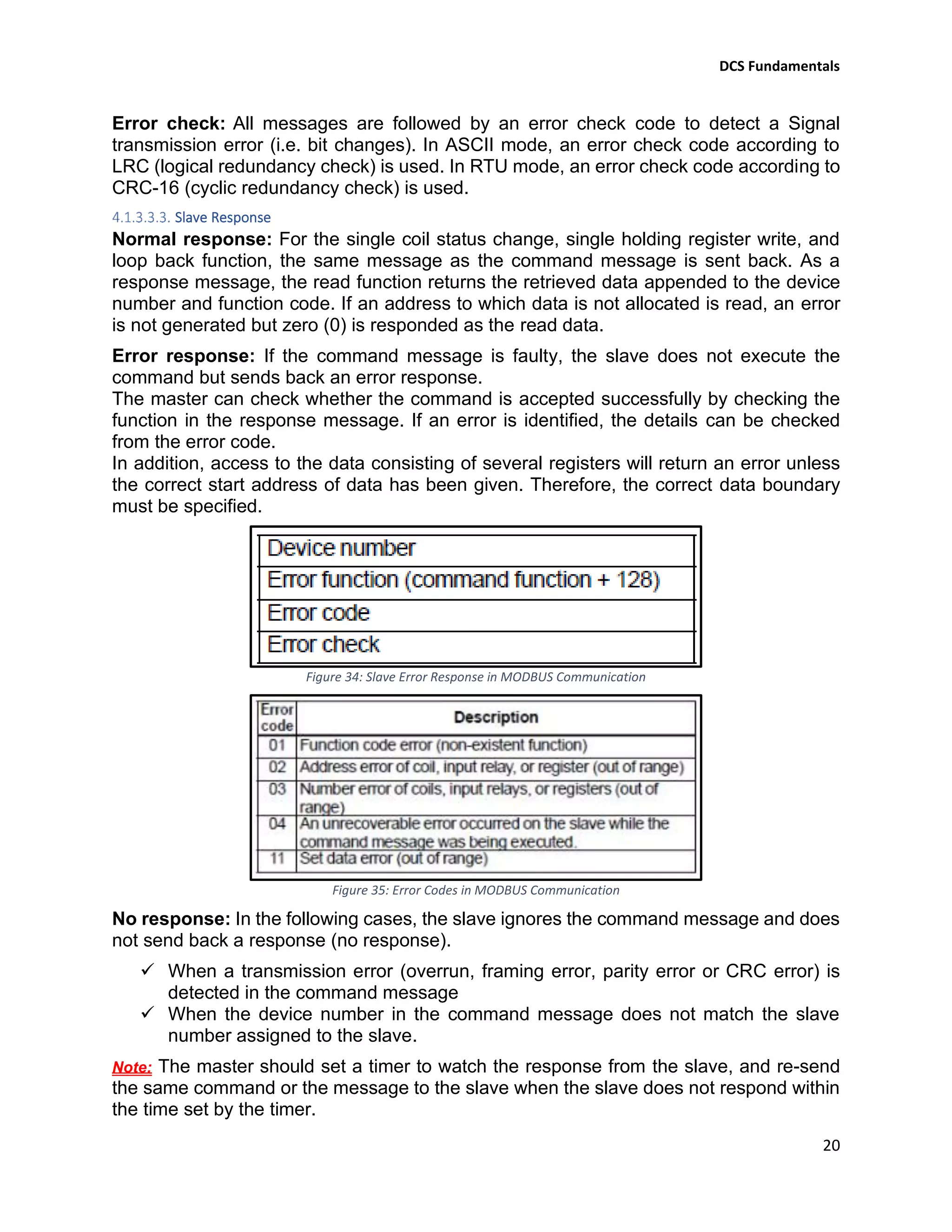

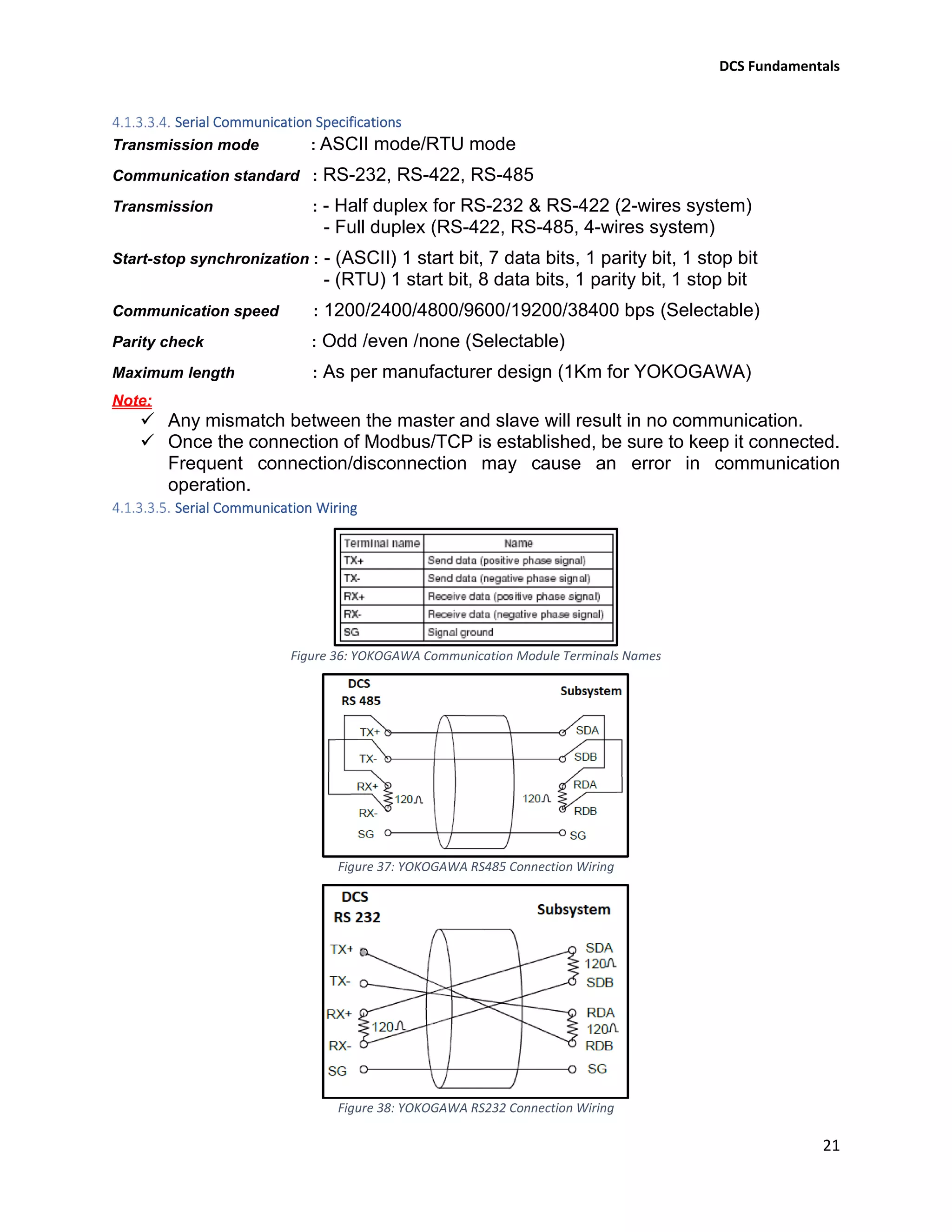

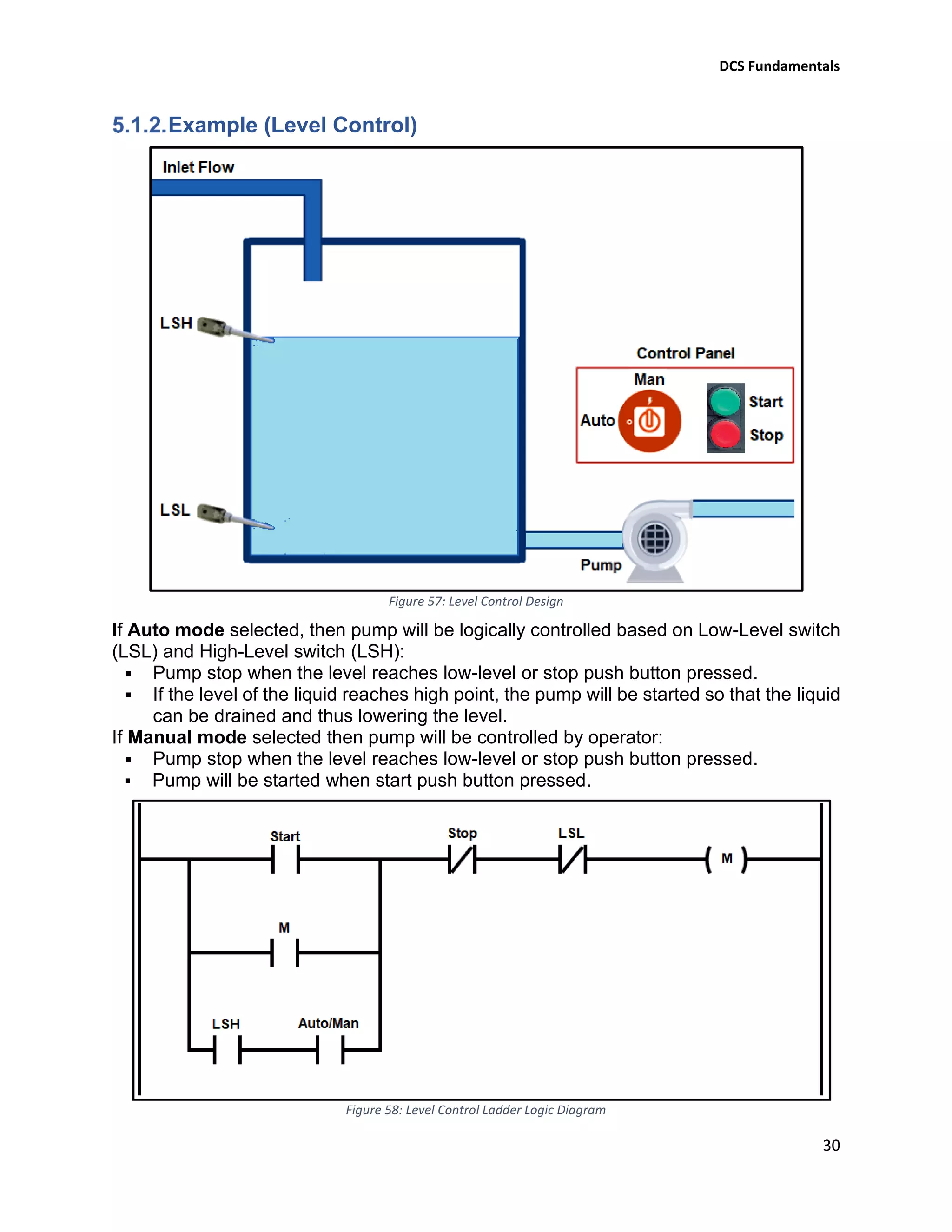

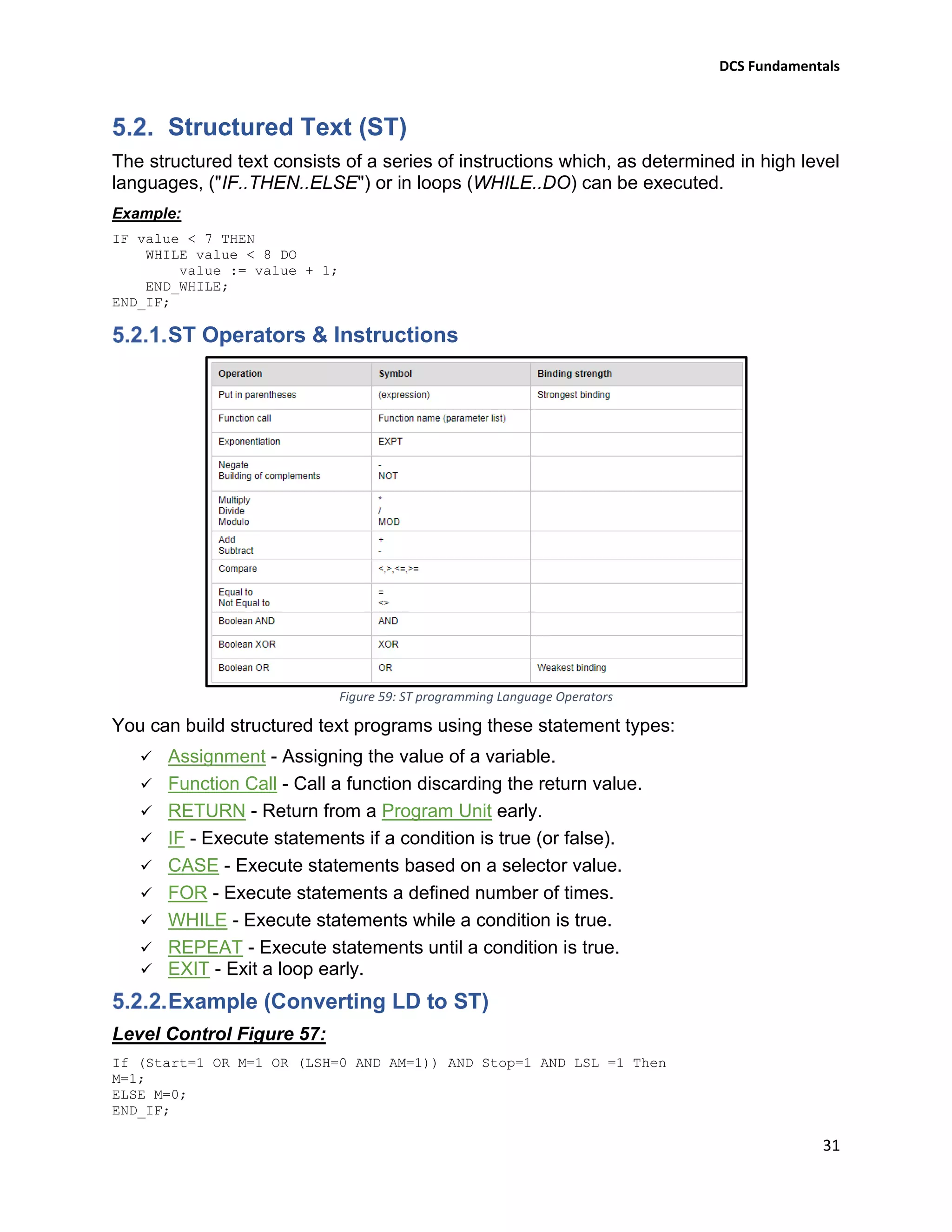

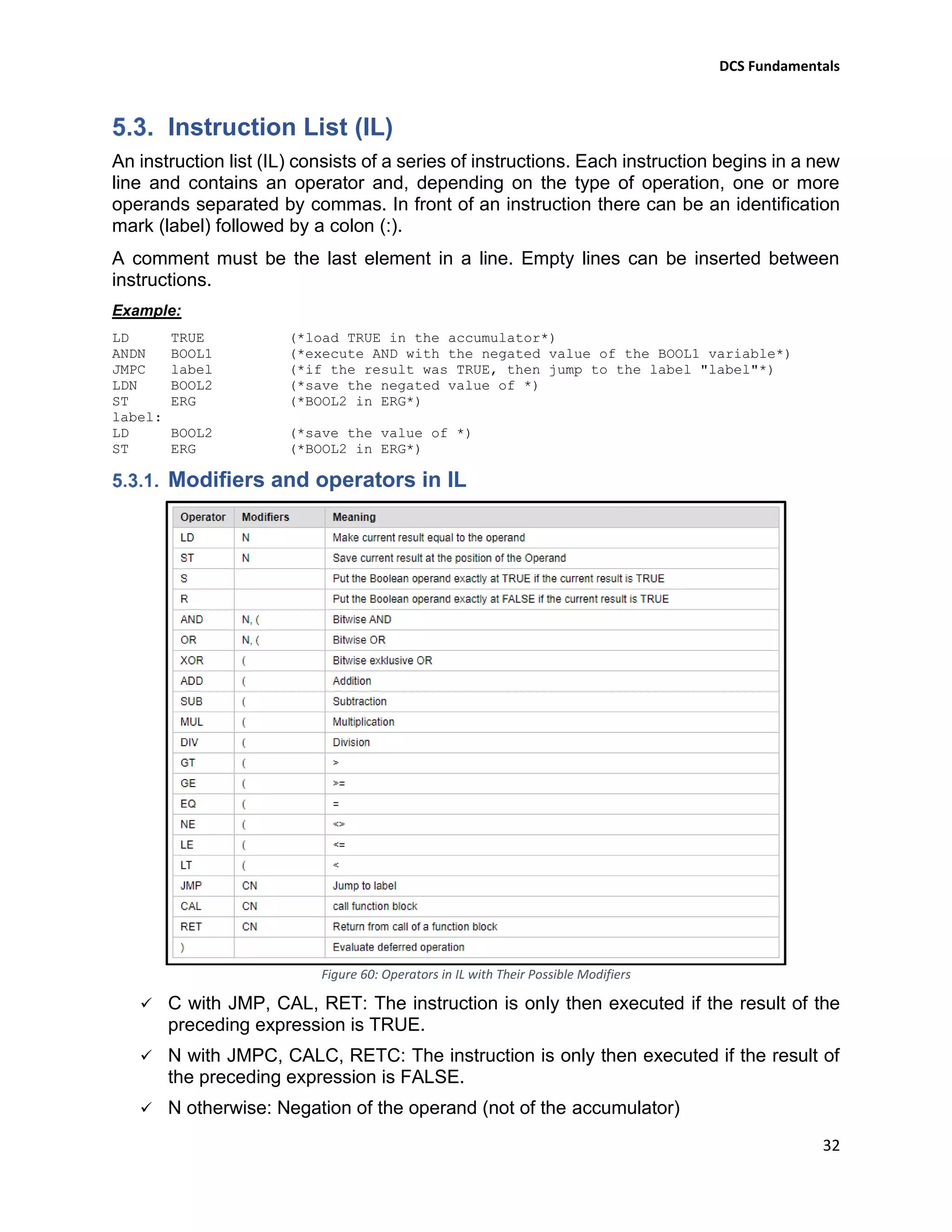

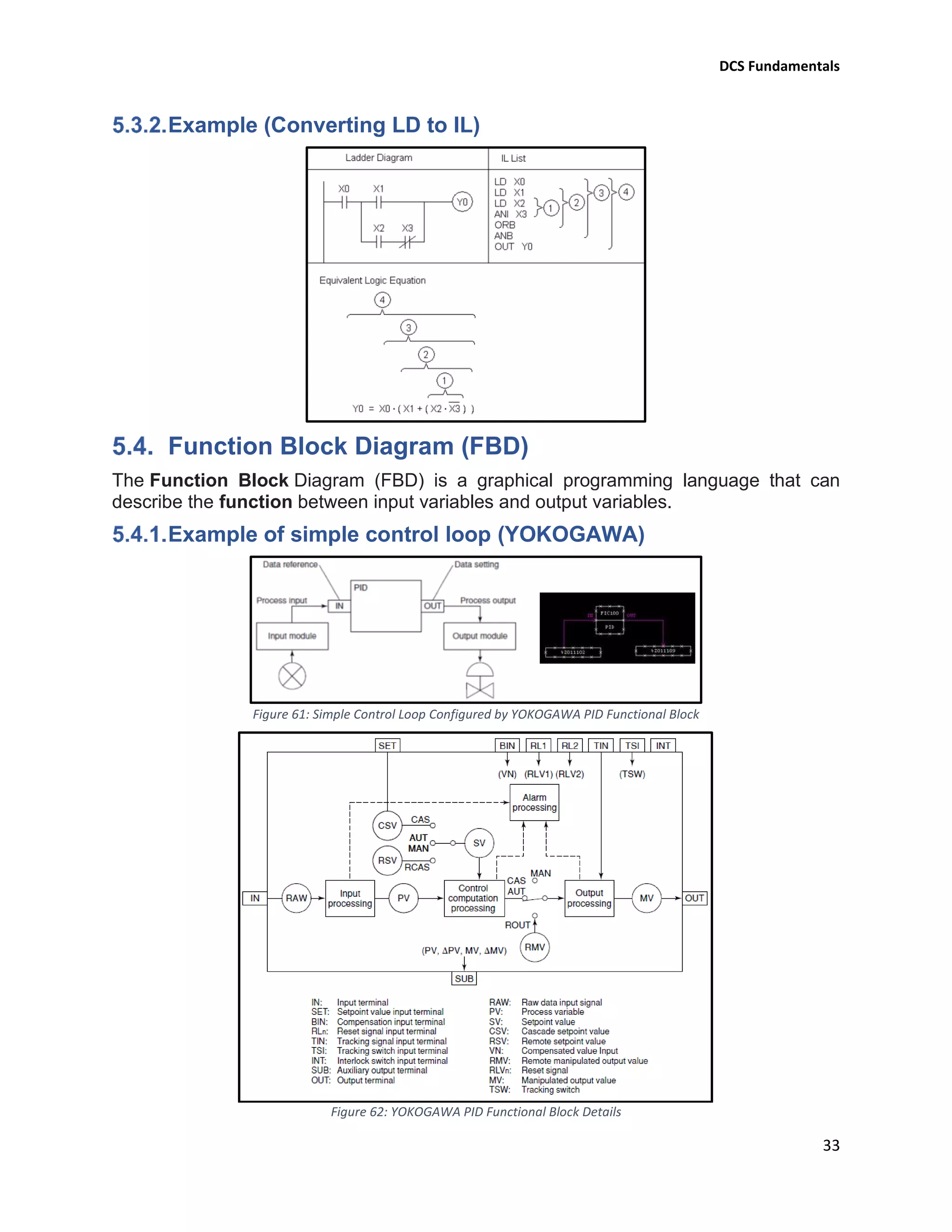

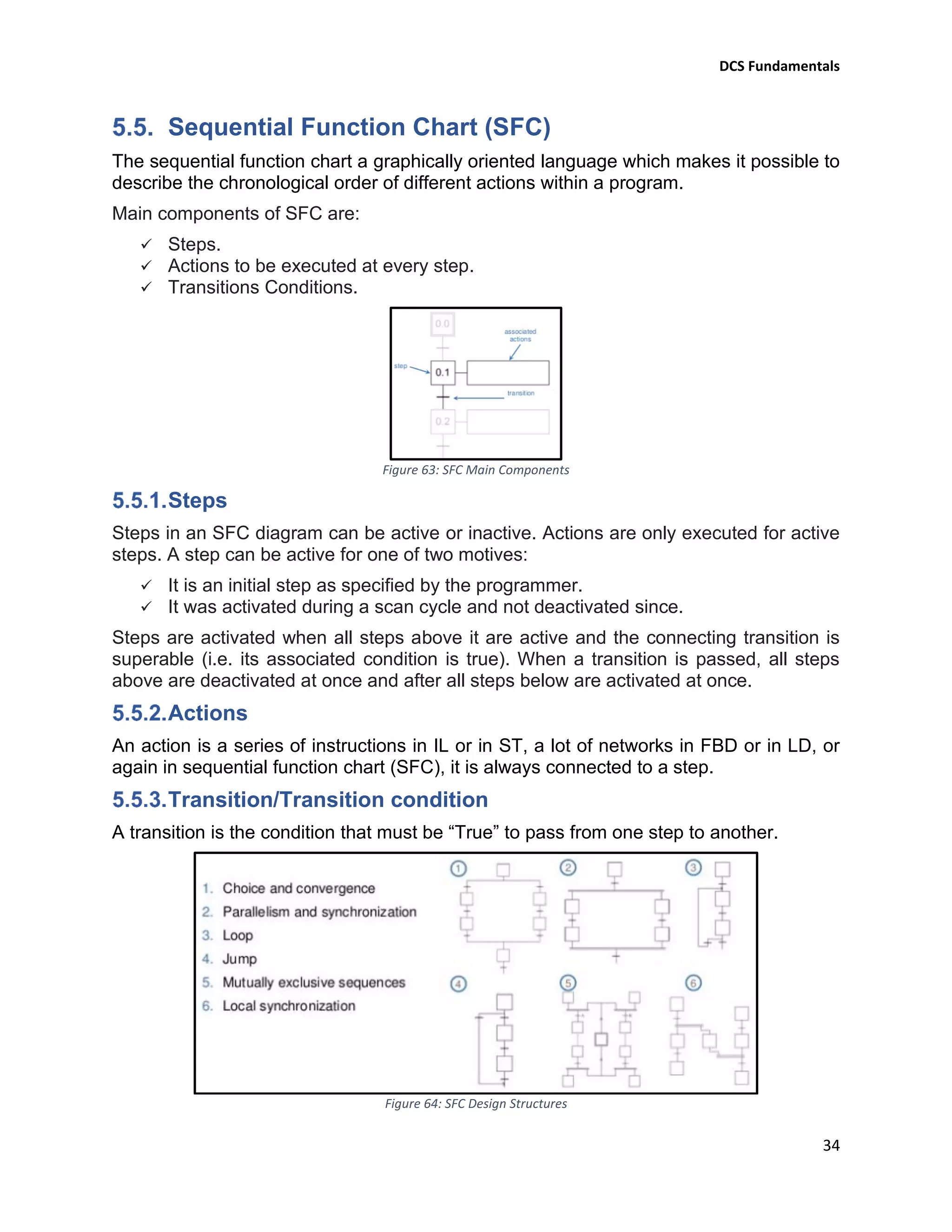

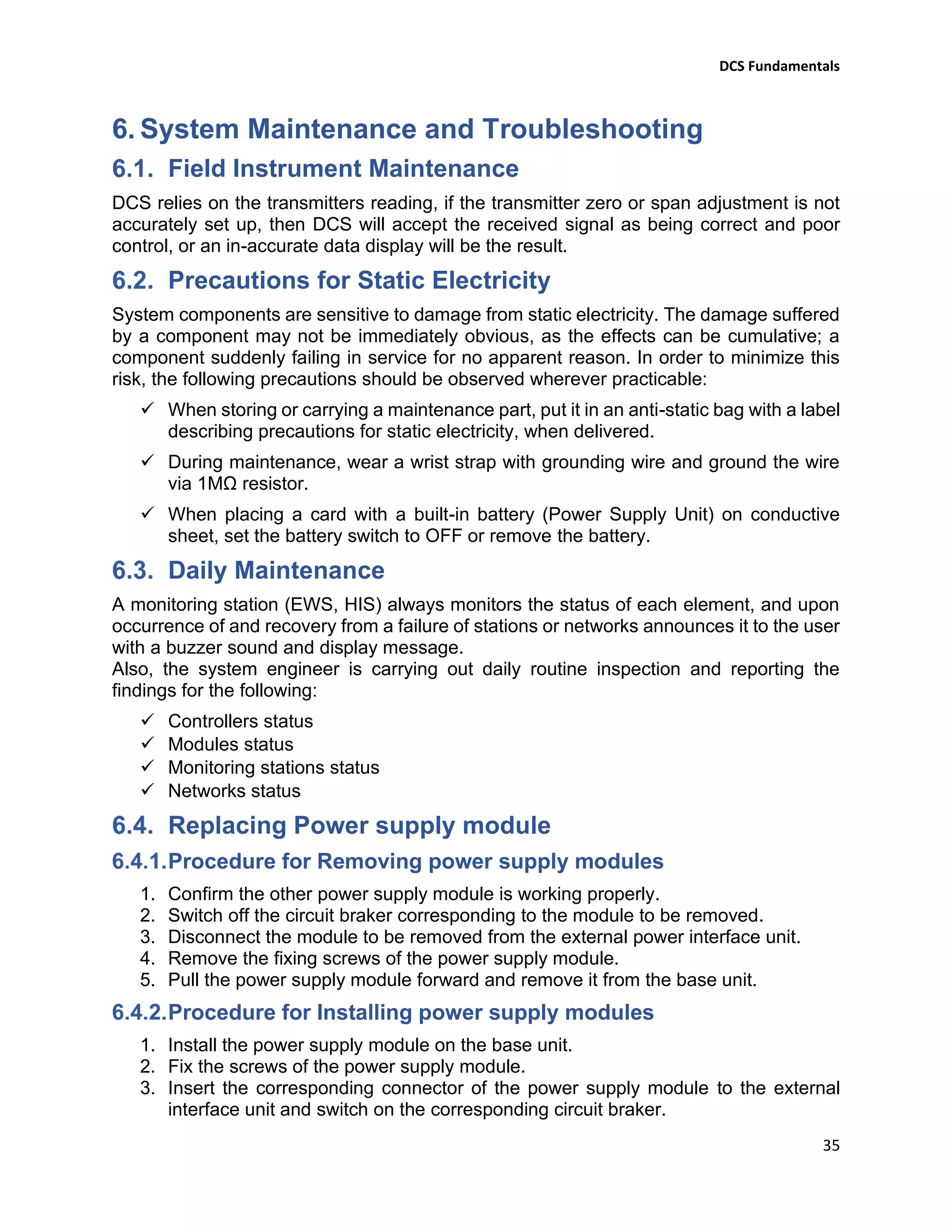

The document provides an in-depth overview of Distributed Control Systems (DCS) in industrial automation, covering their fundamental components, architecture, and operational principles. It explains the role of distributed controllers, CPUs, and various I/O modules, alongside maintenance procedures and advantages/disadvantages of DCS. Additionally, it details programming methods used within DCS, including ladder diagrams and structured text.