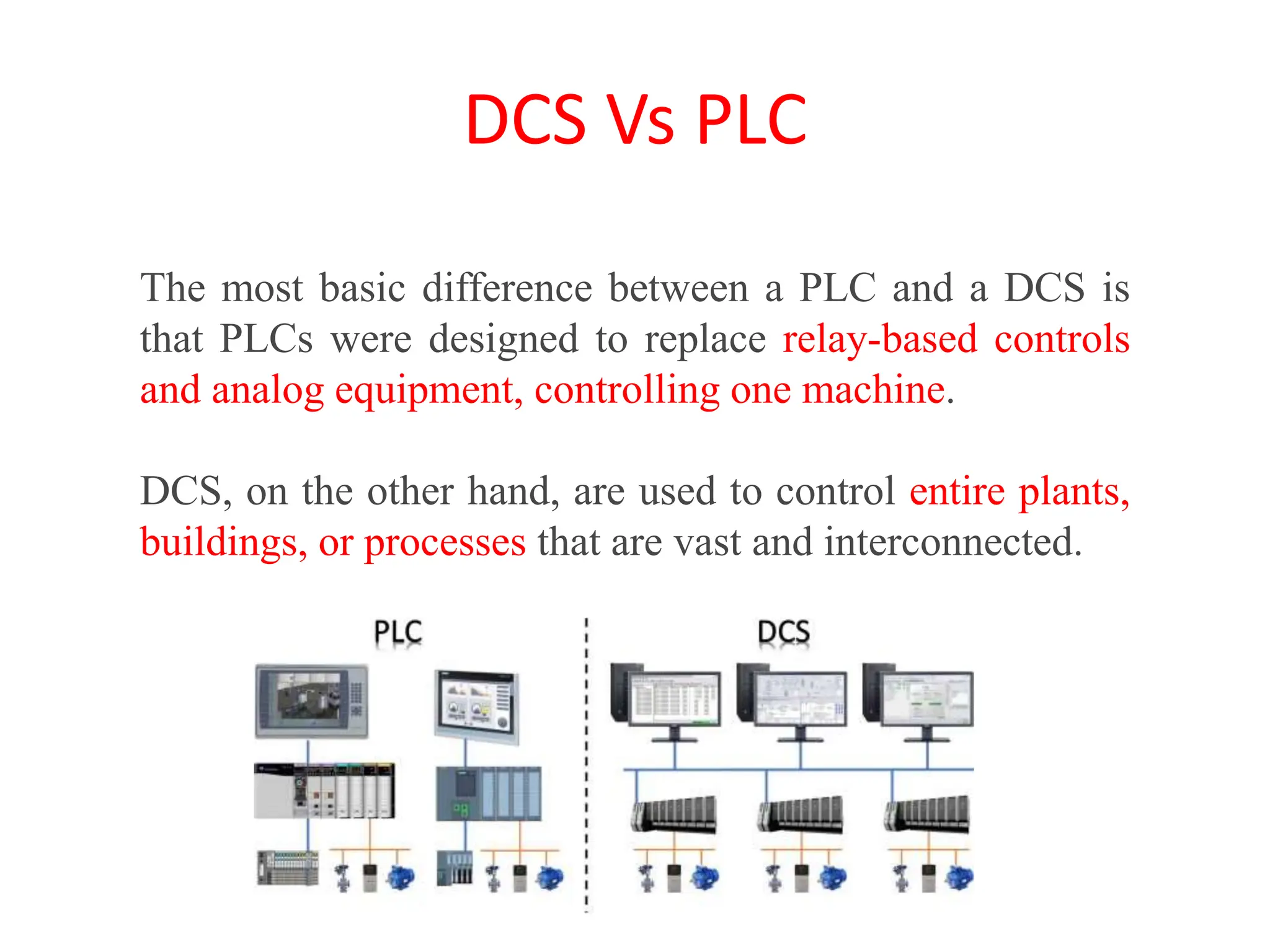

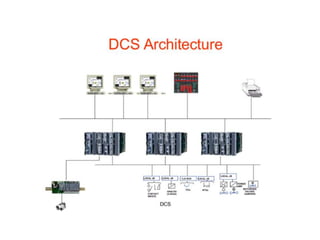

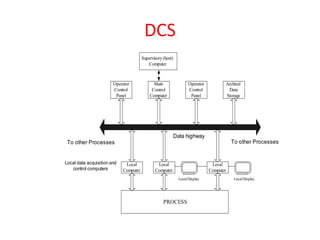

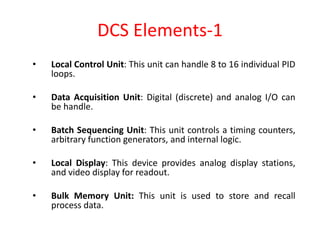

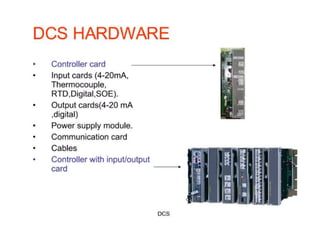

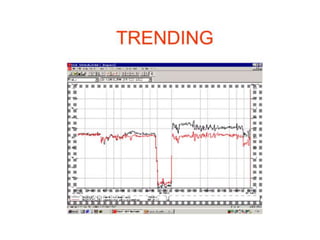

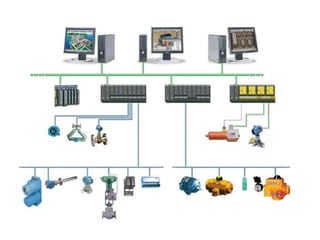

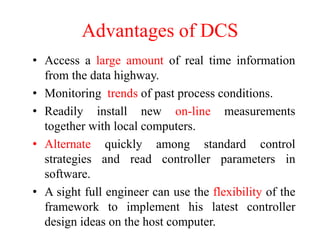

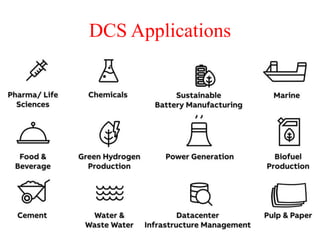

The document compares Distributed Control Systems (DCS) and Programmable Logic Controllers (PLC), highlighting that DCS is designed for controlling large, interconnected processes while PLC typically manages individual machines. DCS integrates various components, such as human-machine interfaces and data acquisition units, to automate plant operations, particularly in continuous manufacturing industries like petrochemicals. The significance of DCS is emphasized in managing complex control loops effectively, improving safety and production efficiency.