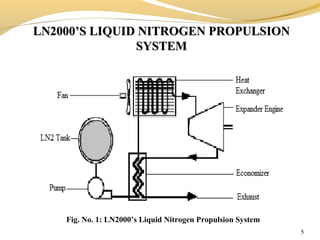

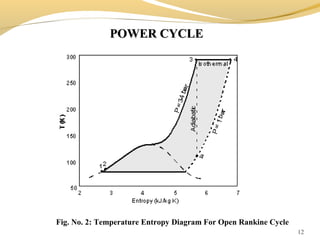

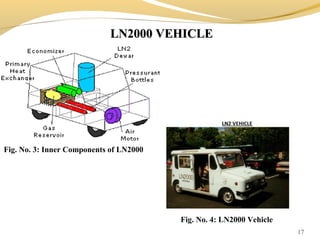

The document presents information on Cryocar, a vehicle that uses liquid nitrogen as fuel. It discusses the history of liquid nitrogen propulsion research. The key components of a liquid nitrogen propulsion system are described including the cryogen storage vessel, pump, economizer, heat exchanger, and expander engine. The open Rankine power cycle is explained. Advantages include reduced emissions, but disadvantages include energy needed to liquefy nitrogen and potential safety issues if nitrogen leaks. The LN2000 vehicle developed at the University of Washington is provided as an example.

![REFERENCESREFERENCES

19

JOURNALS

[1] Abilash Vijayrao Nishane, (2016) “Cryogenic Liquid Nitrogen as a Fuel

for Zero Emission Vehicles (Z.E.V)”, International Journal and Magazine

of Engineering, Technology, Management and Research.

[2] Rahul Singh Choudhary, (2015) “Hydrogen as a Non-Polluting Fuel”,

International Journal of Advance Research, IJOAR.org.

[3] Akil Garg, Kartik Jakhu, Kishan Singh, (2015) “Cryogenic Technology

and Rocket Engines” International Journal of Aerospace and Mechanical

Engineering.

[4] Pankaj Soni, Gopal Sahu, Prakash Kumar Sen, Ritesh Sharma, (2014ss)

“A Review on Cryogenic Engine” International Journal for Research in

Science and Engineering Technology (IJRASET).](https://image.slidesharecdn.com/cryocar-170331144921/85/Cryocar-19-320.jpg)