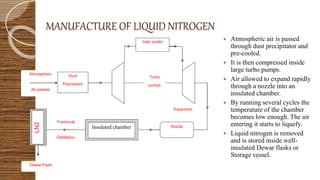

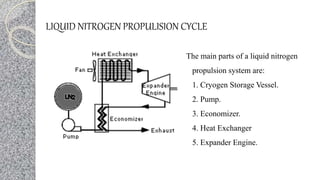

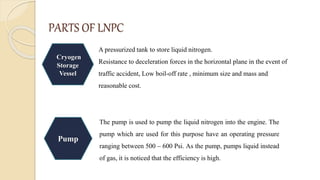

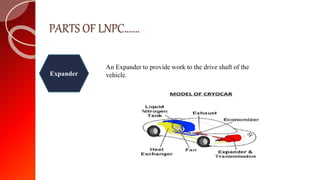

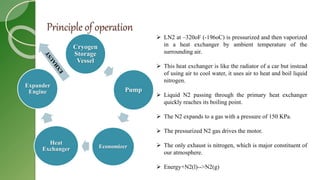

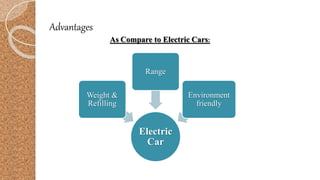

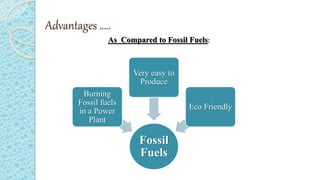

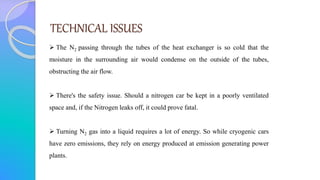

This document summarizes a seminar presentation on cryogenic vehicles (cryocars) that use liquid nitrogen as fuel. It describes how liquid nitrogen is produced, the basic parts and operation of a liquid nitrogen propulsion system, including a cryogen storage vessel, pump, economizer, heat exchanger and expander engine. The document discusses the improved efficiency of newer cryocars compared to early models and notes advantages over electric and fossil-fueled vehicles, while also outlining technical issues that have prevented commercialization, such as safety concerns and the energy required to produce liquid nitrogen.