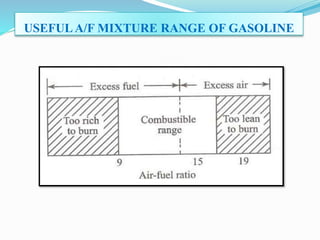

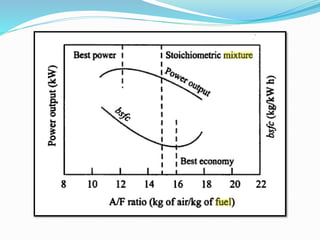

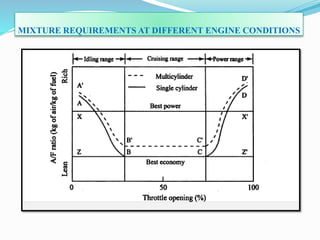

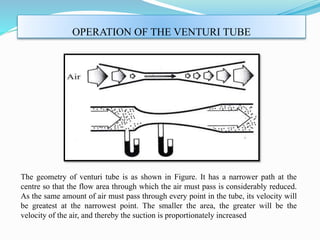

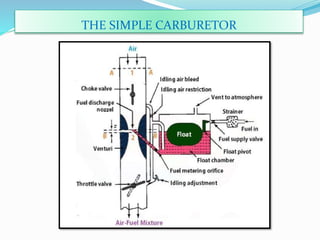

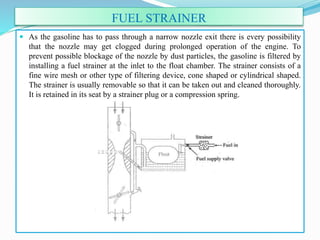

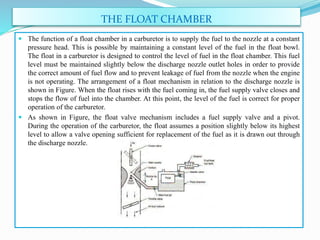

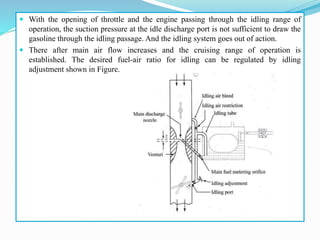

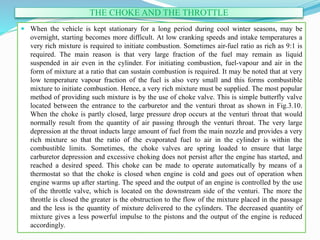

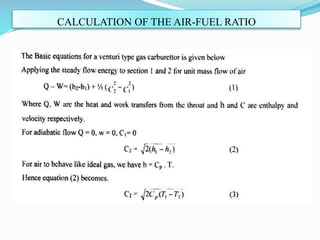

This document provides an overview of carburetion in spark-ignition engines. It discusses how a carburetor works to prepare a combustible air-fuel mixture for the engine cylinders. The key components of a carburetor are described, including the venturi tube, float chamber, jets, and choke. The document also covers the different air-fuel mixture requirements for idling, cruising, and high power operations and how the carburetor supplies the appropriate mixture for different engine conditions. Overall, the carburetor is a device that atomizes fuel and mixes it with air in varying proportions to provide the engine cylinders with a combustible air-fuel mixture for operation under all load conditions and speeds.