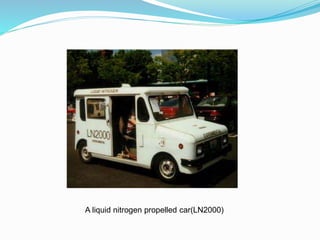

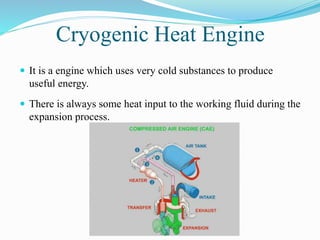

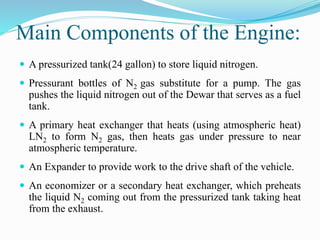

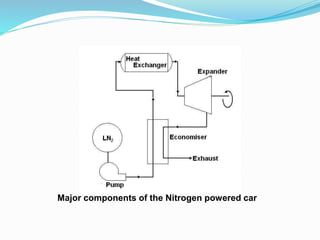

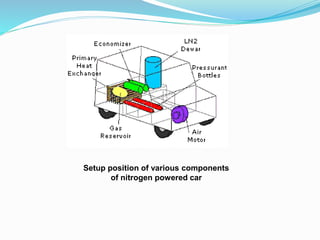

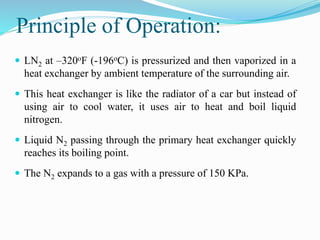

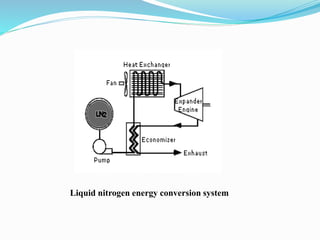

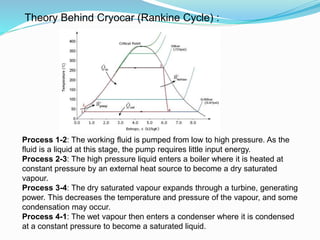

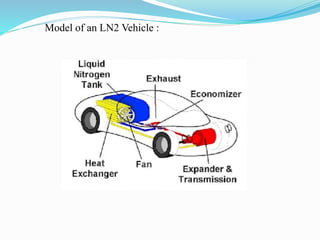

This document discusses liquid nitrogen vehicles. It provides an overview of the history and development of liquid nitrogen vehicles in the 1990s. It describes the key components and operating principles of liquid nitrogen vehicles, which use cryogenic heat engines to convert liquid nitrogen into a gas to power the vehicle. The document outlines the advantages of liquid nitrogen vehicles over electric vehicles, as well as current drawbacks and reasons they have not been commercialized.