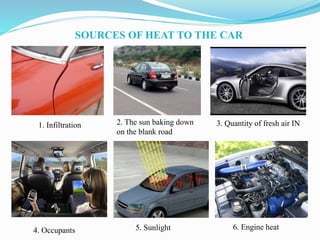

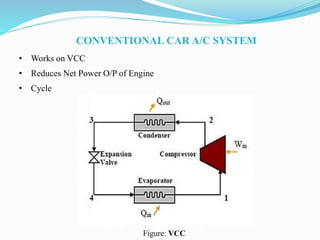

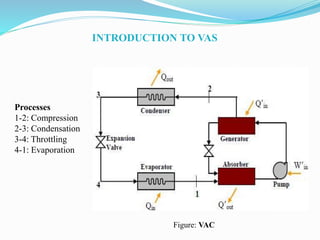

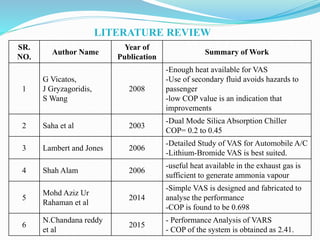

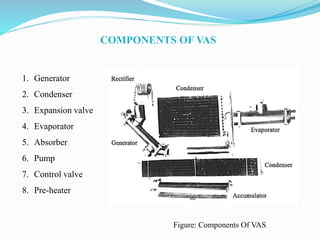

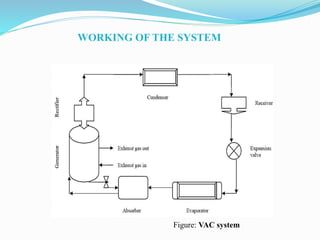

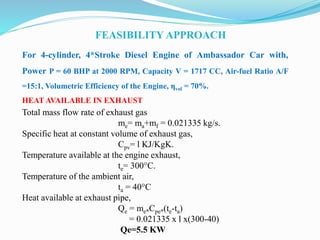

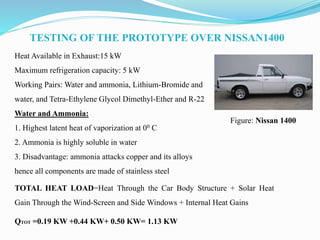

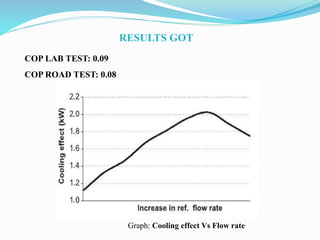

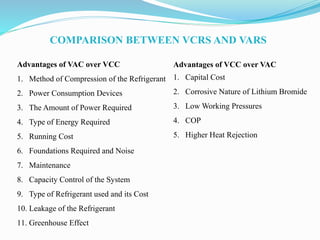

The seminar by Mr. B. A. Wadekar discusses a vapor absorption cooling system using exhaust heat for automobile air conditioning, comparing it with traditional vapor compression systems. Key points include the components and methodology of the vapor absorption system, current trends in energy efficiency, and a review of relevant literature. The document highlights testing results from a prototype based on a Nissan 1400 vehicle, showcasing advantages and drawbacks of both cooling systems.