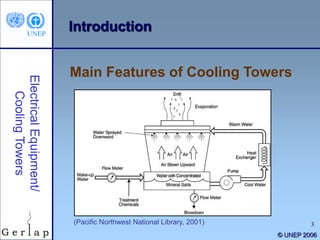

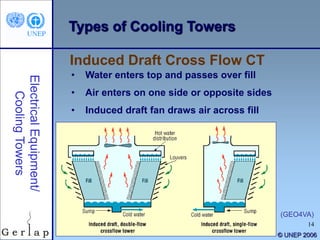

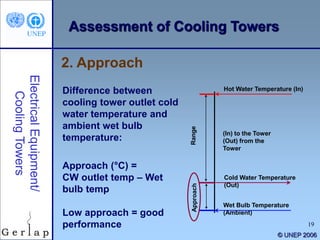

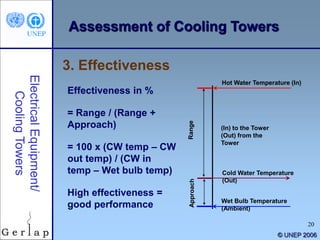

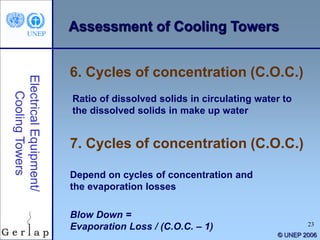

This document provides information on cooling towers, including types, components, performance parameters for assessment, and opportunities for improved energy efficiency. It discusses the main types of cooling towers as natural draft, mechanical draft (including forced draft, induced draft counter flow and cross flow), and compares fill media options. Key performance parameters covered include range, approach, effectiveness, cooling capacity, and cycles of concentration. Energy efficiency opportunities discussed include selecting an appropriately sized tower, optimizing fill media, improving water distribution and treatment, upgrading fans and motors, and reducing drift losses.