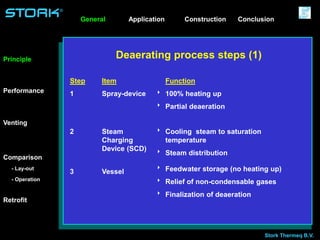

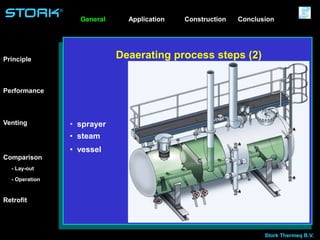

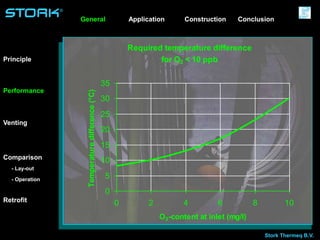

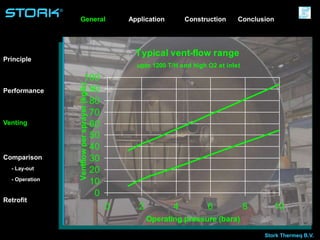

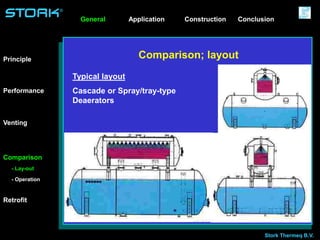

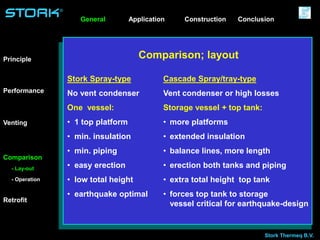

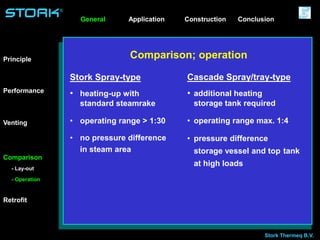

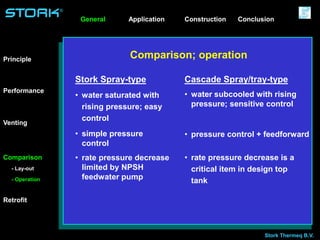

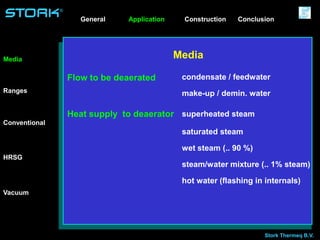

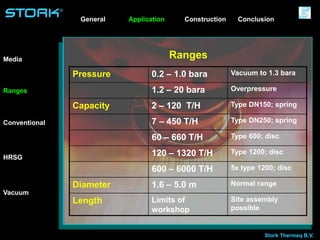

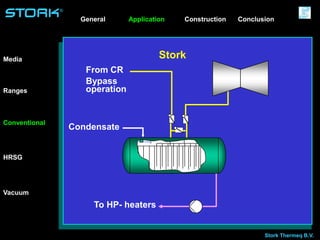

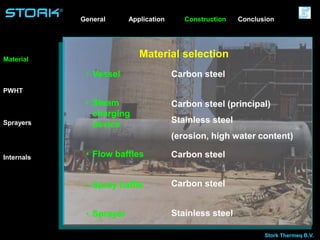

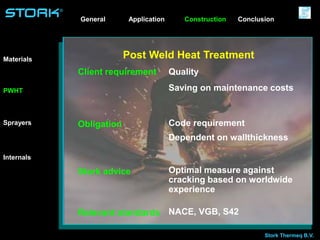

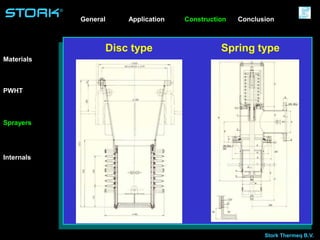

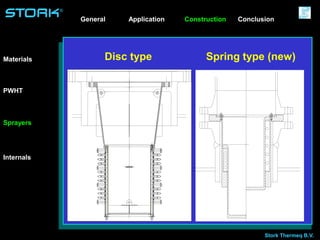

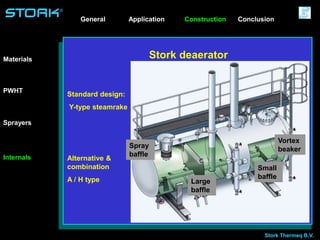

This document provides information on Stork Thermeq B.V.'s spray-type deaerator system. It describes the deaerating process which involves heating, partial deaeration, and cooling of feedwater using a spray device, steam charging device, and vessel. It compares the layout and operation of spray-type deaerators to cascade or spray/tray-type systems, noting advantages of the Stork design including its more compact size, simpler operation, and flexibility. The document also outlines typical design parameters for pressure, capacity, materials used, and internal components.