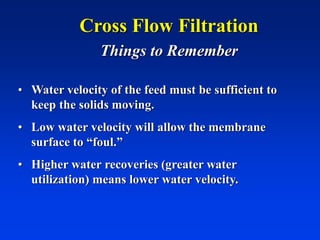

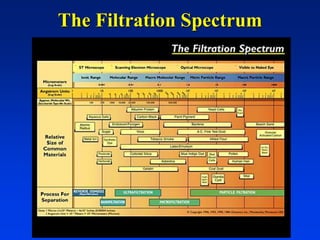

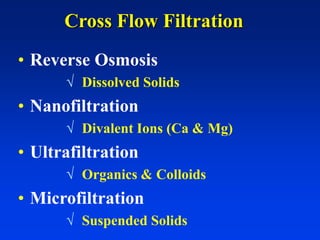

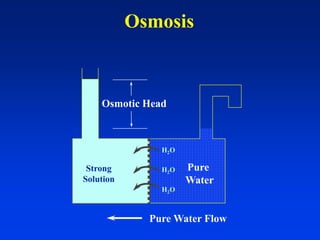

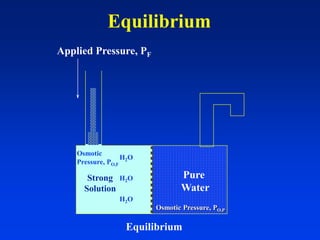

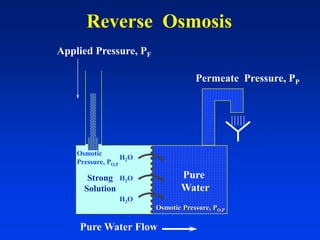

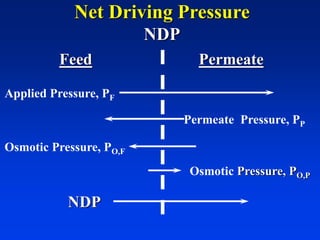

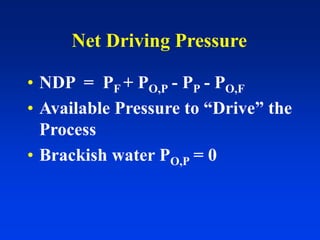

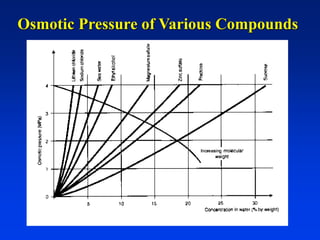

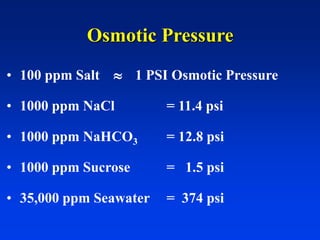

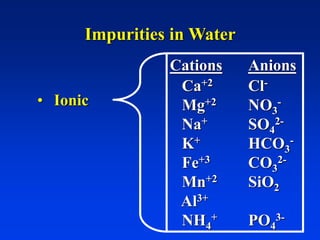

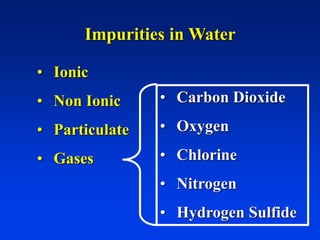

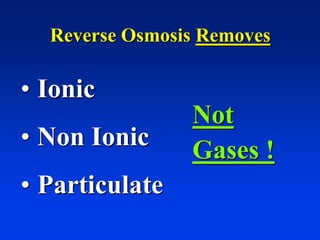

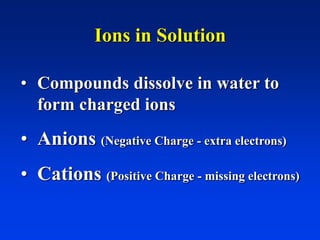

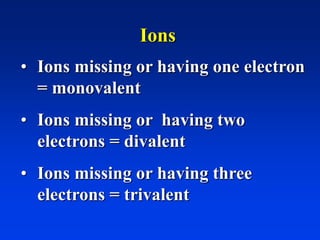

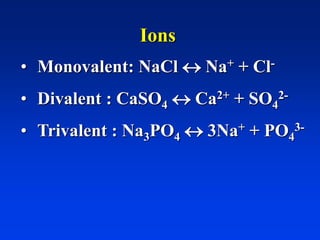

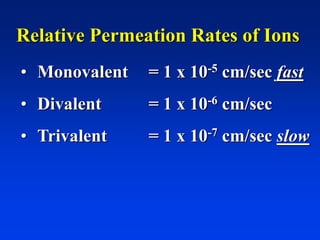

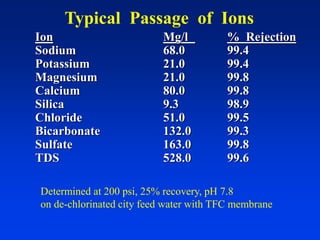

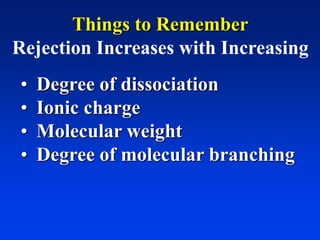

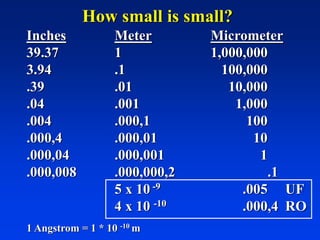

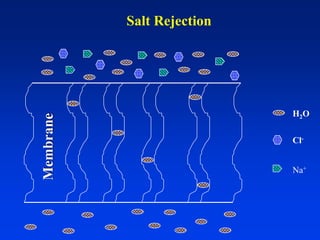

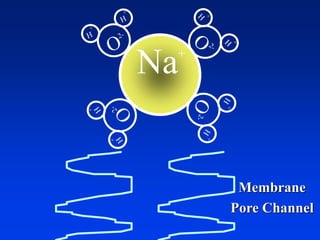

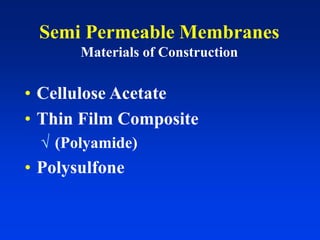

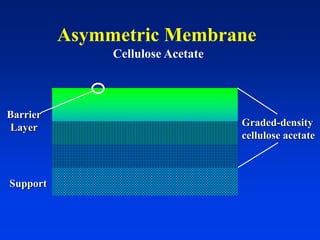

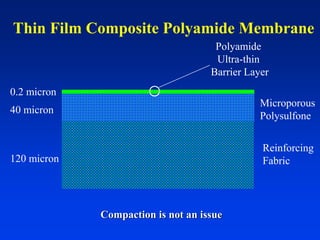

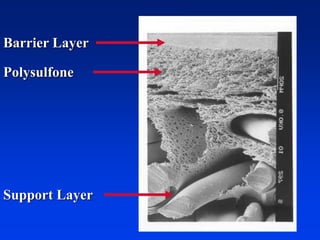

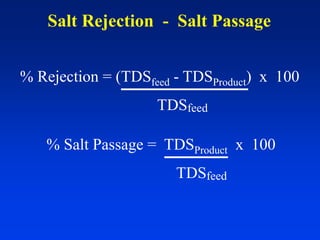

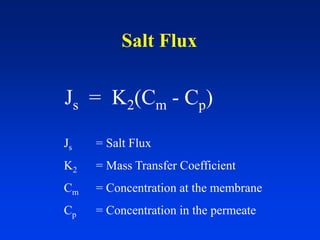

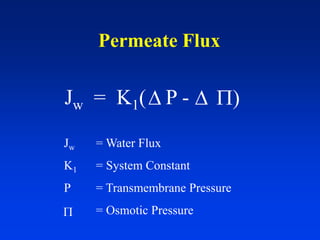

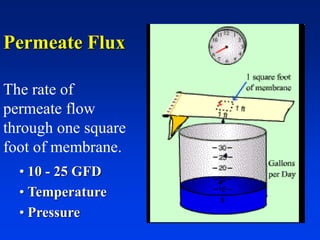

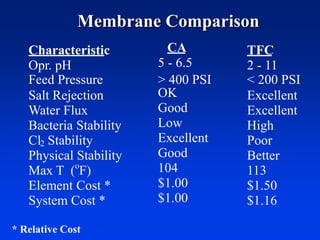

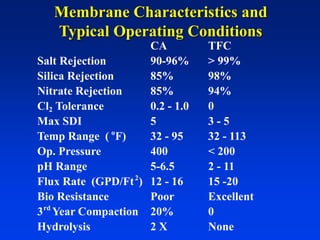

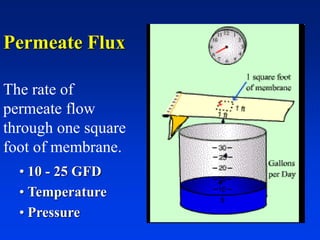

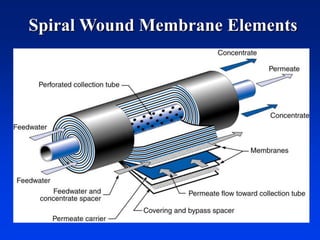

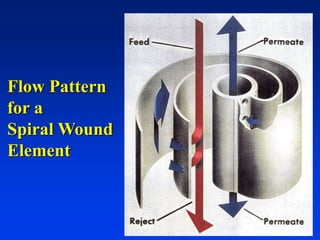

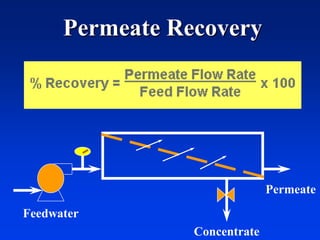

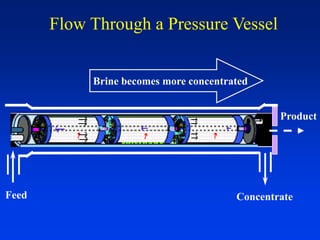

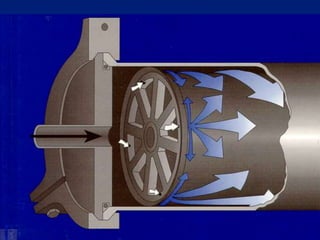

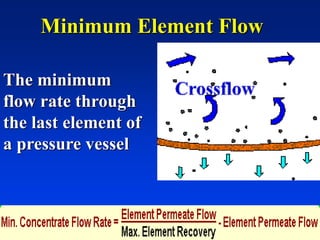

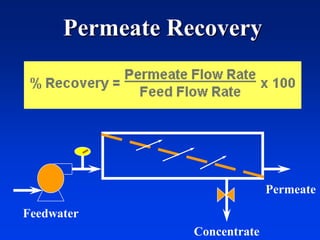

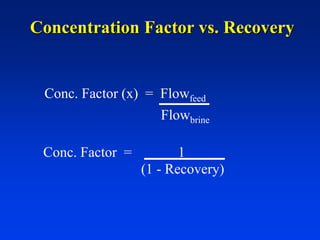

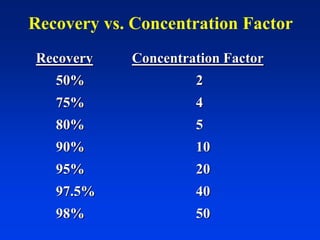

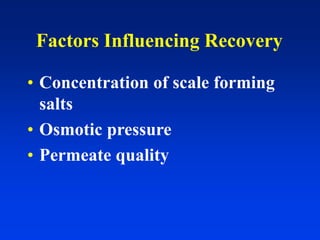

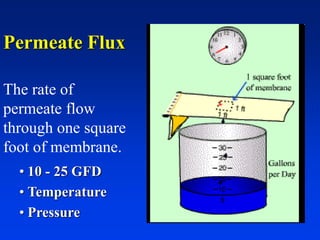

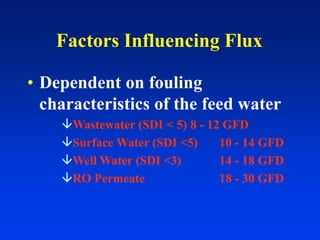

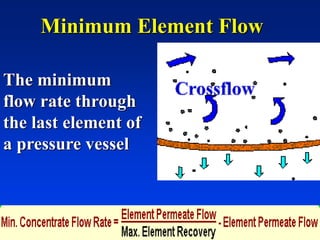

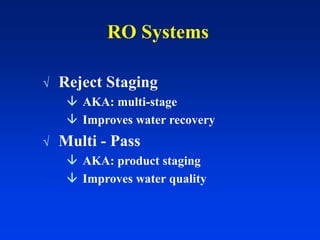

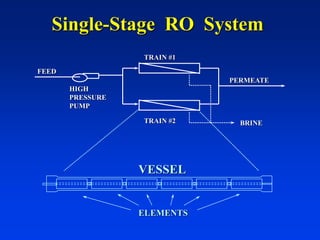

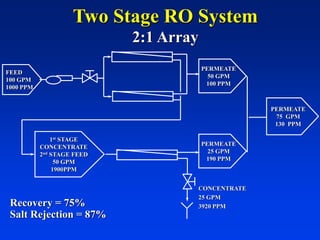

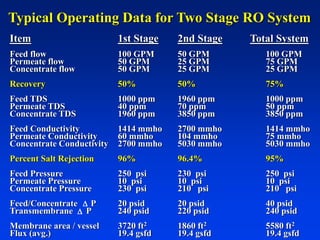

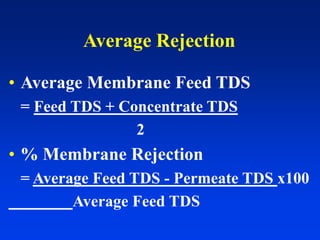

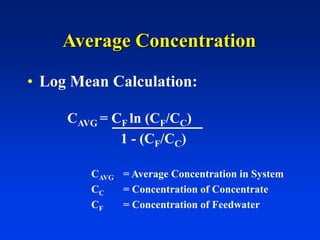

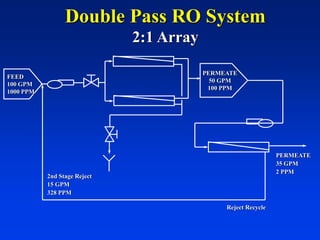

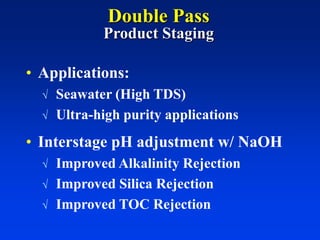

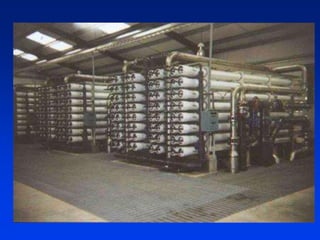

This presentation provides an overview of reverse osmosis membrane filtration fundamentals. It discusses types of filtration processes including reverse osmosis and nanofiltration. It covers key concepts such as osmosis, reverse osmosis, net driving pressure and rejection rates of different ion types. The presentation also examines reverse osmosis membrane types, configurations, and system design considerations including permeate recovery, flux, and staging approaches.