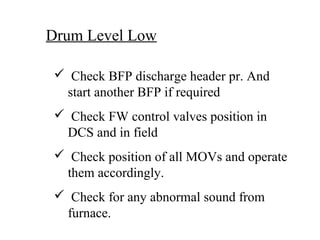

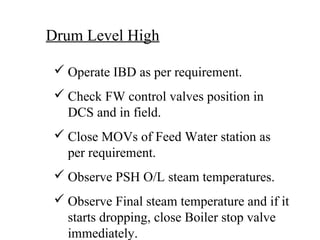

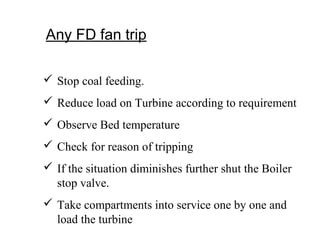

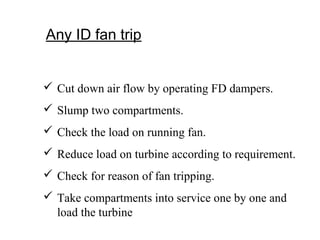

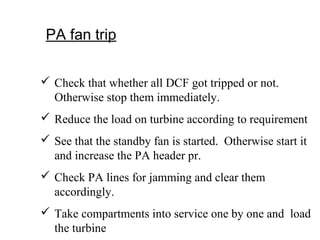

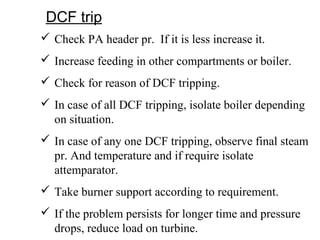

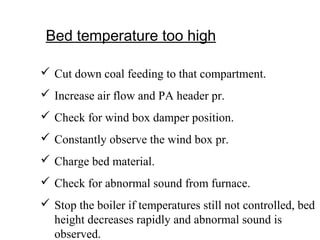

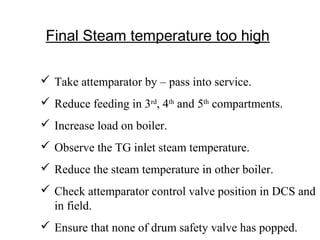

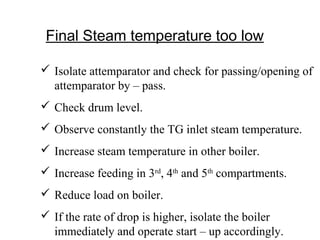

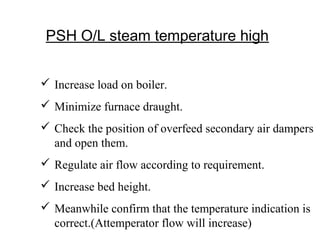

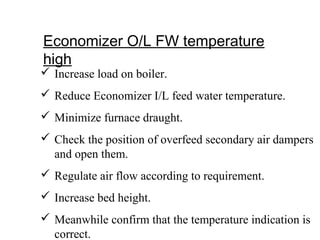

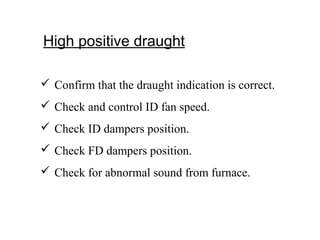

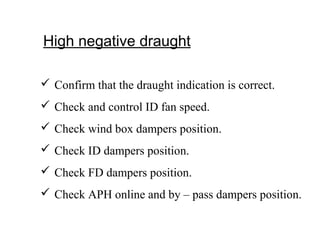

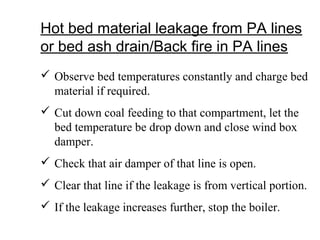

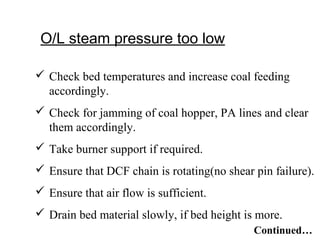

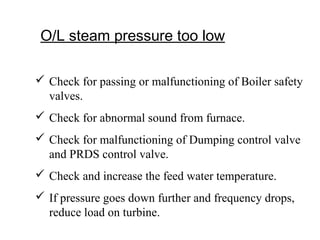

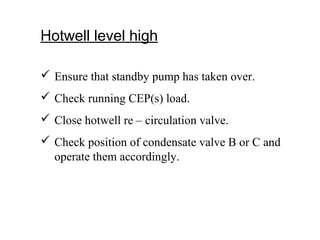

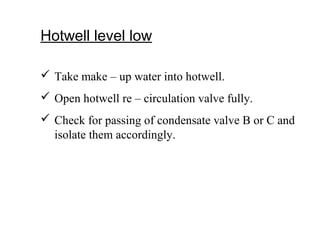

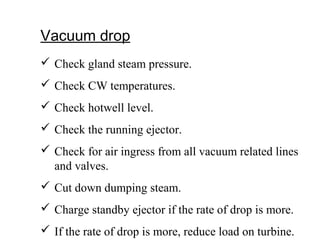

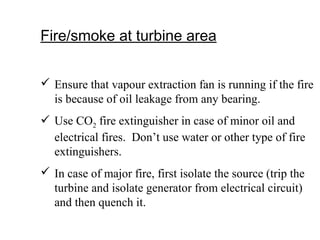

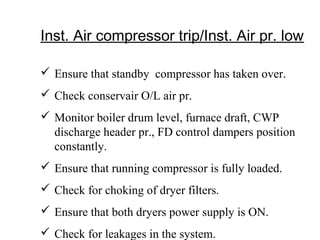

This document lists various boiler and turbine emergencies and provides instructions on actions to take in response to each emergency. It covers issues like low or high drum levels, fan trips, temperature deviations, pressure changes, pump trips, fires and more. The instructions emphasize safeguarding equipment, investigating causes, monitoring key parameters and load reductions as needed.