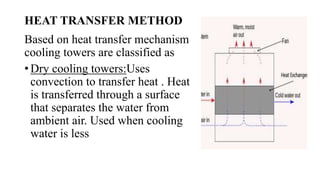

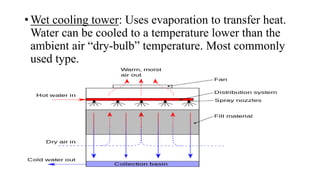

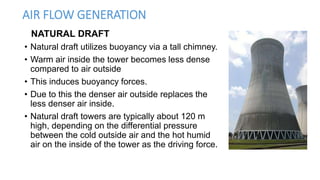

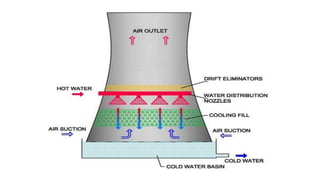

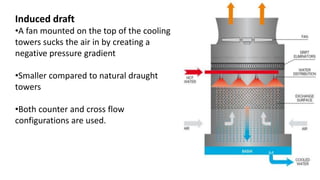

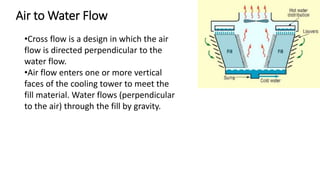

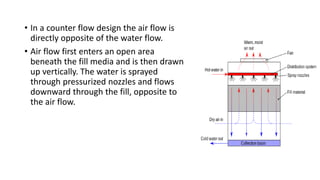

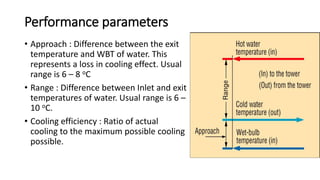

Cooling towers are heat rejection devices that lower the temperature of a water stream by rejecting waste heat to the atmosphere. They are classified based on heat transfer methods (dry or wet) and air flow generation (natural or mechanical draft). Key performance parameters include approach, range, and cooling efficiency, with important components such as frames, fills, and drift eliminators supporting their function.