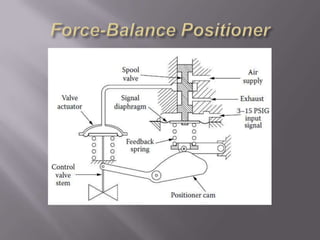

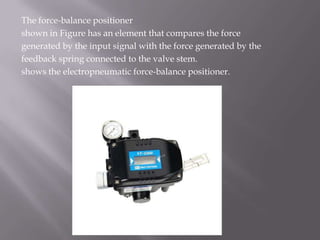

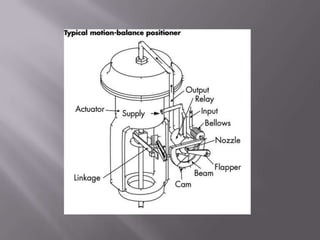

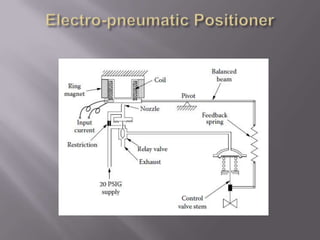

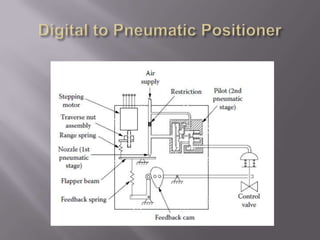

A positioner is a feedback controller device that ensures a control valve is in the correct position according to a control signal. It senses the valve's position and compares it to the signal from an I/P converter. Based on the difference or "error", it positions the valve to reduce the error to zero. Positioners improve the accuracy of a valve's response by reducing issues like friction, dynamic forces, and non-linearities. Modern digital positioners no longer require an I/P converter and offer additional features like diagnostics and partial stroke testing.