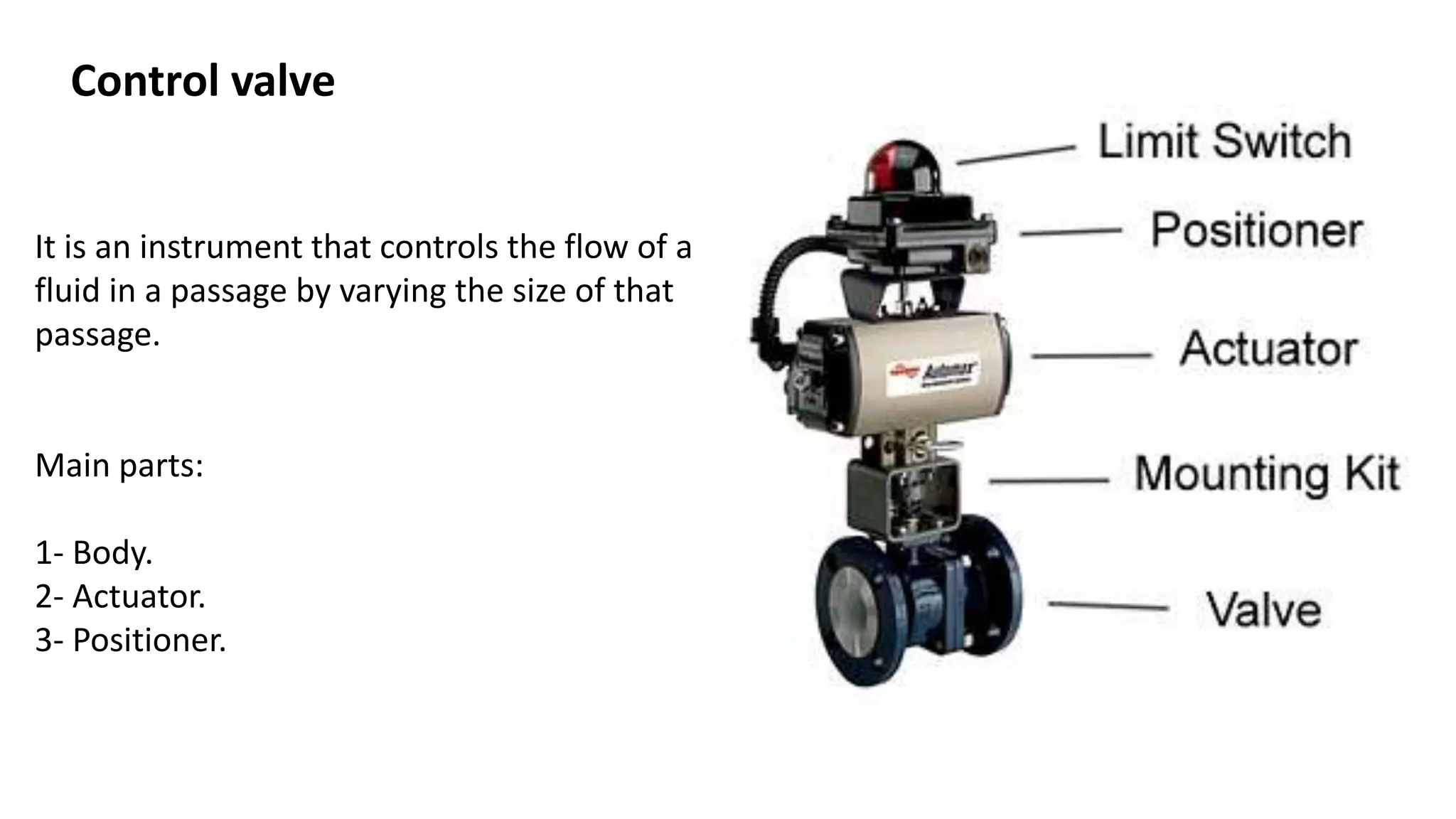

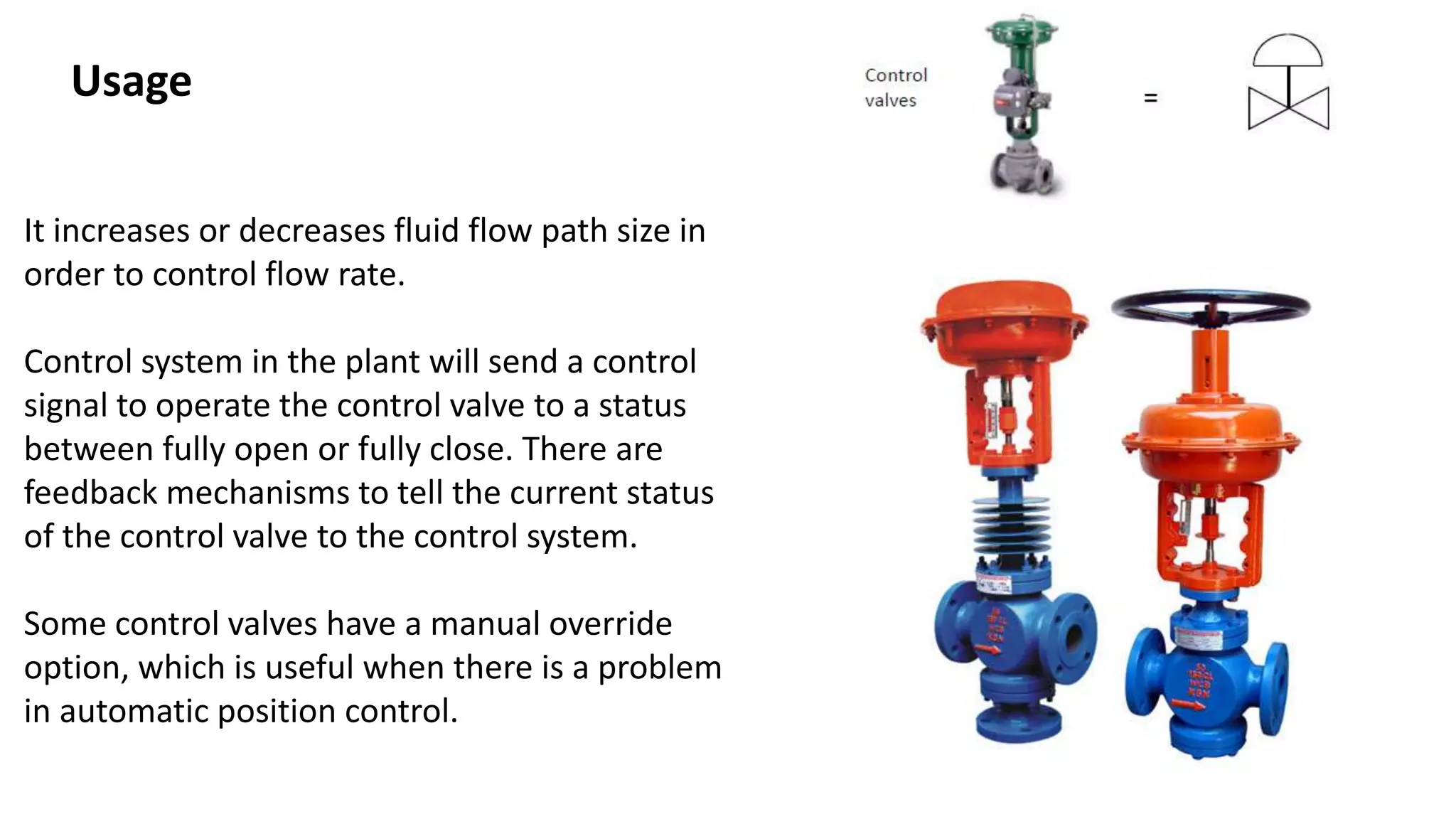

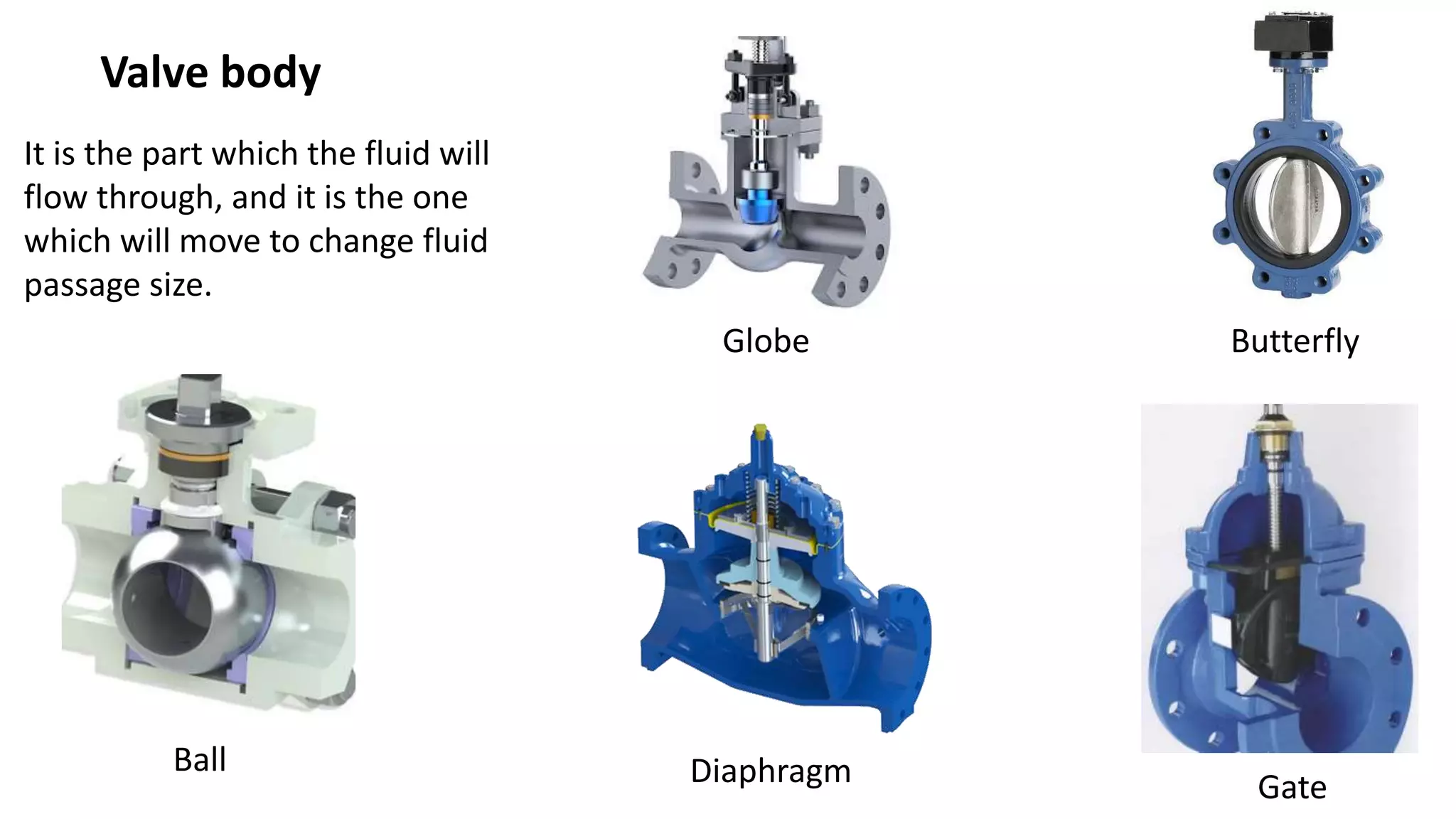

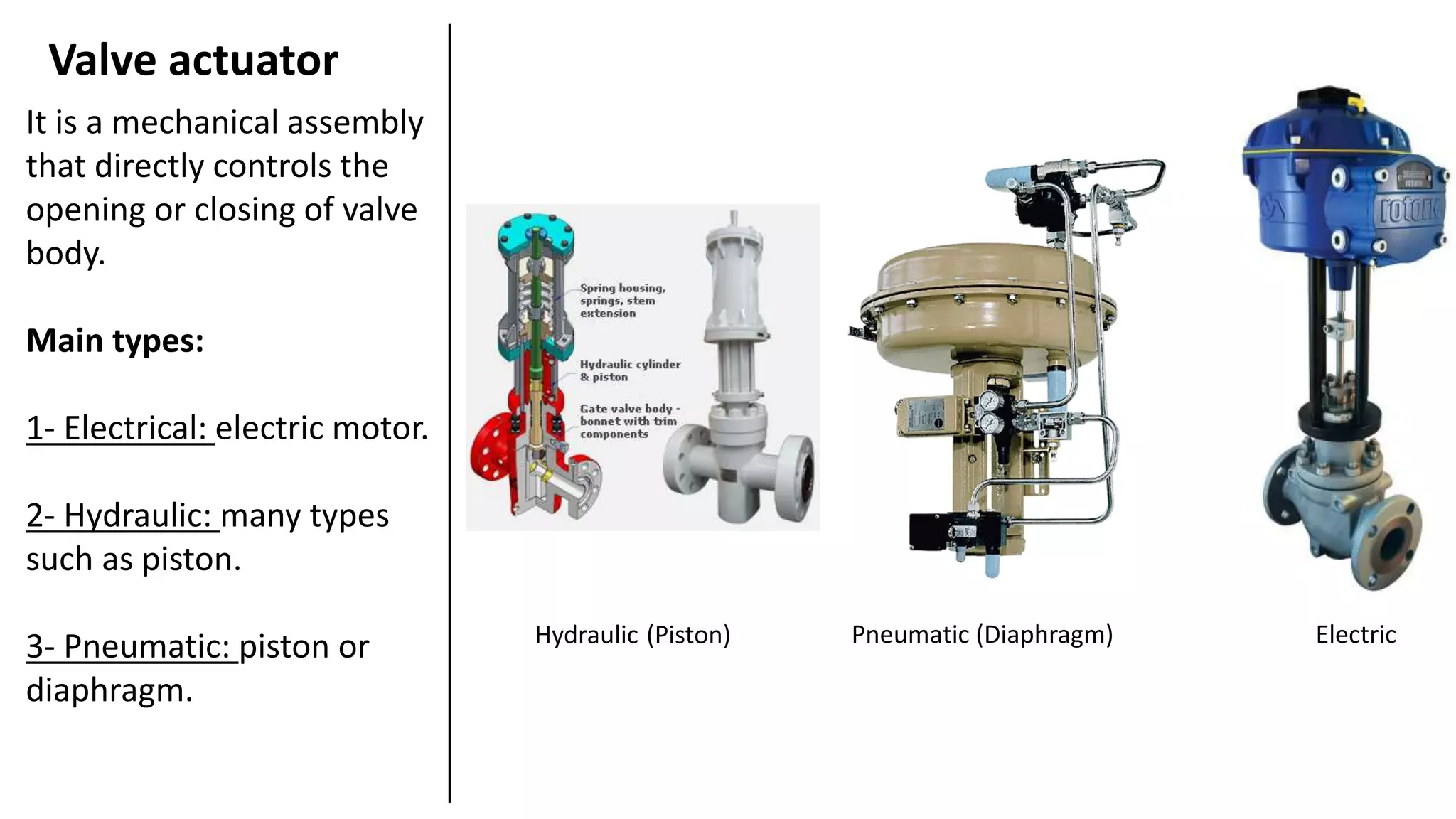

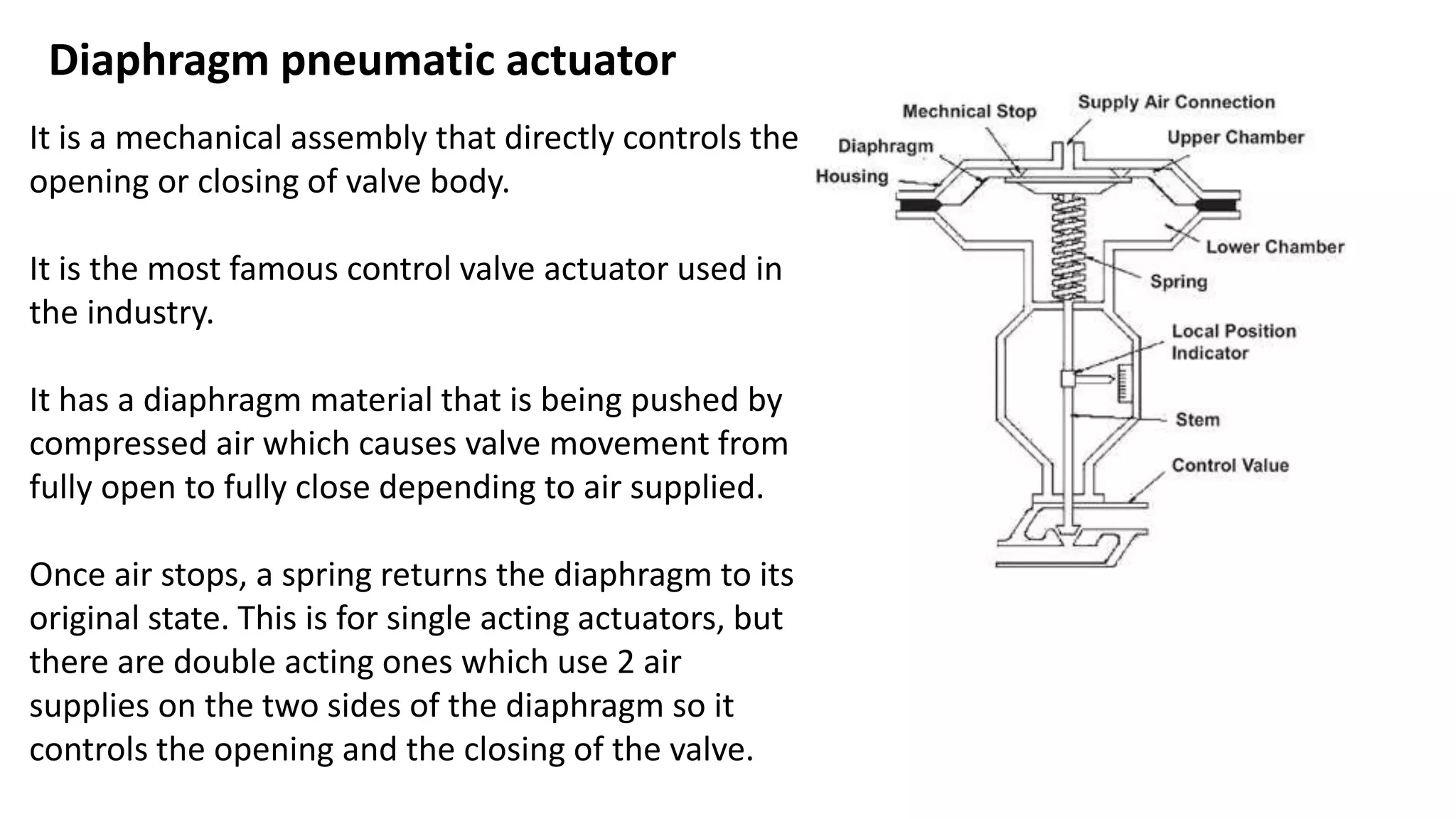

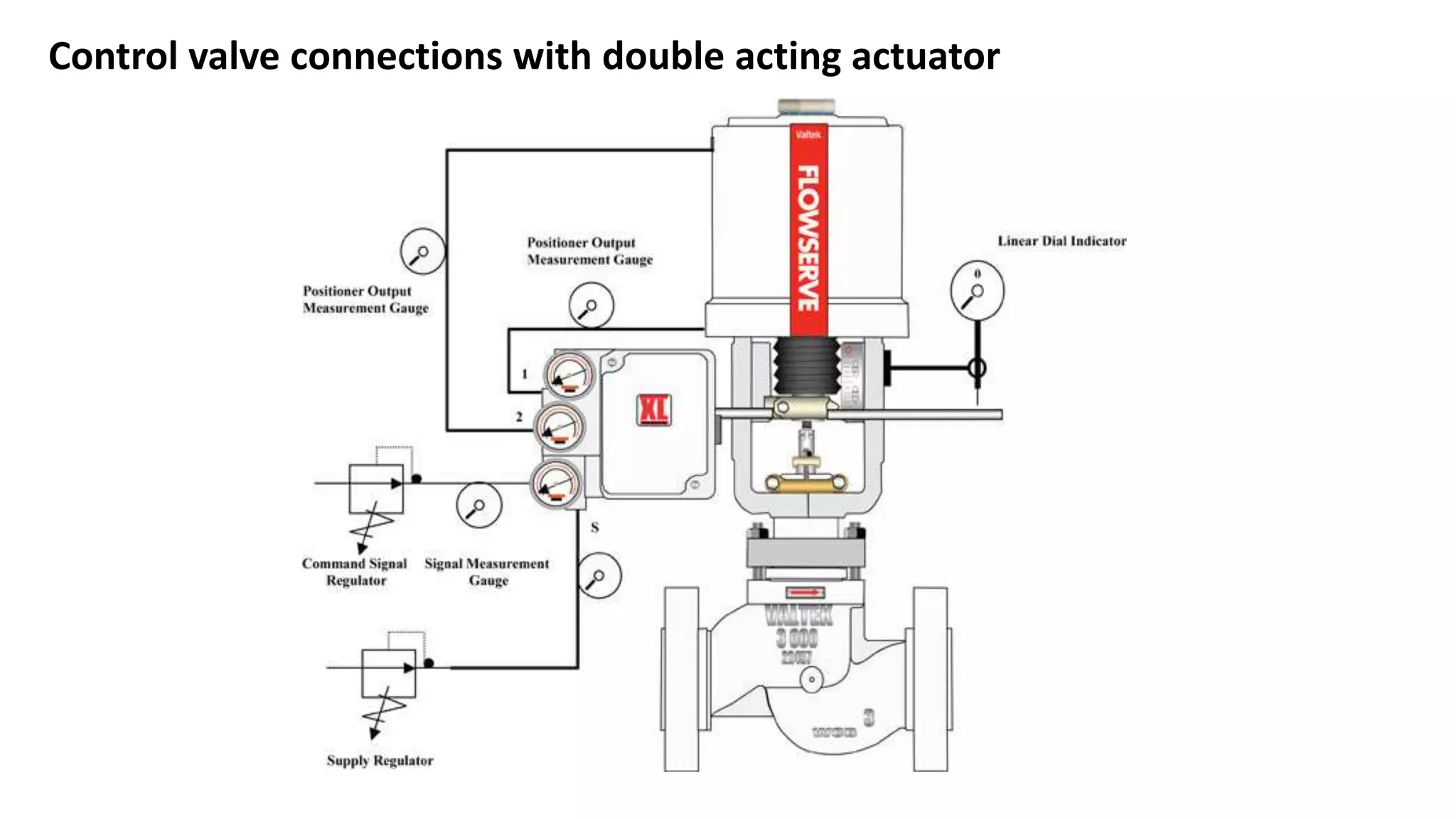

Control valves are instruments that control the flow of fluids through passages by varying the size of the passageway. They have a body, actuator, and positioner. The actuator directly controls the opening and closing of the valve body in response to signals from the positioner. Common actuator types include pneumatic, hydraulic, and electric. Pneumatic actuators typically use compressed air and a diaphragm to move the valve stem and vary the flow opening. Positioners receive control signals and ensure the actuator moves the valve to the desired position.