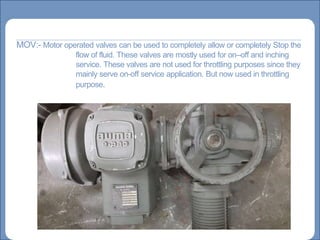

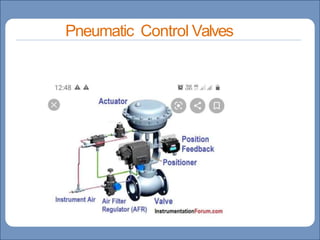

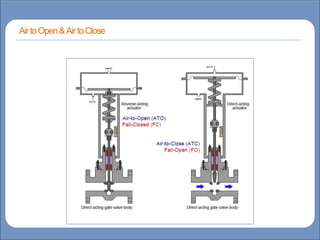

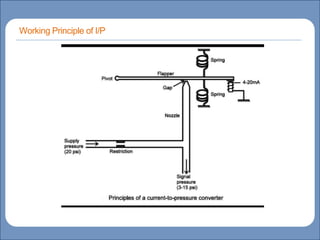

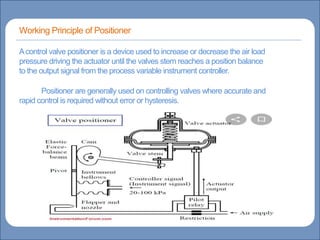

The document discusses MOV (motor operated valves) and pneumatic control valves. It covers the types and applications of MOV, differences between MOV and pneumatic control valves, and problems with MOV. It also discusses pneumatic control valves in more detail, including the main types (air to open and air to close), accessories like regulators and I/P converters, and the working principles of I/P converters and positioners. The document is a presentation on control valves for a course on instrumentation and control basics.