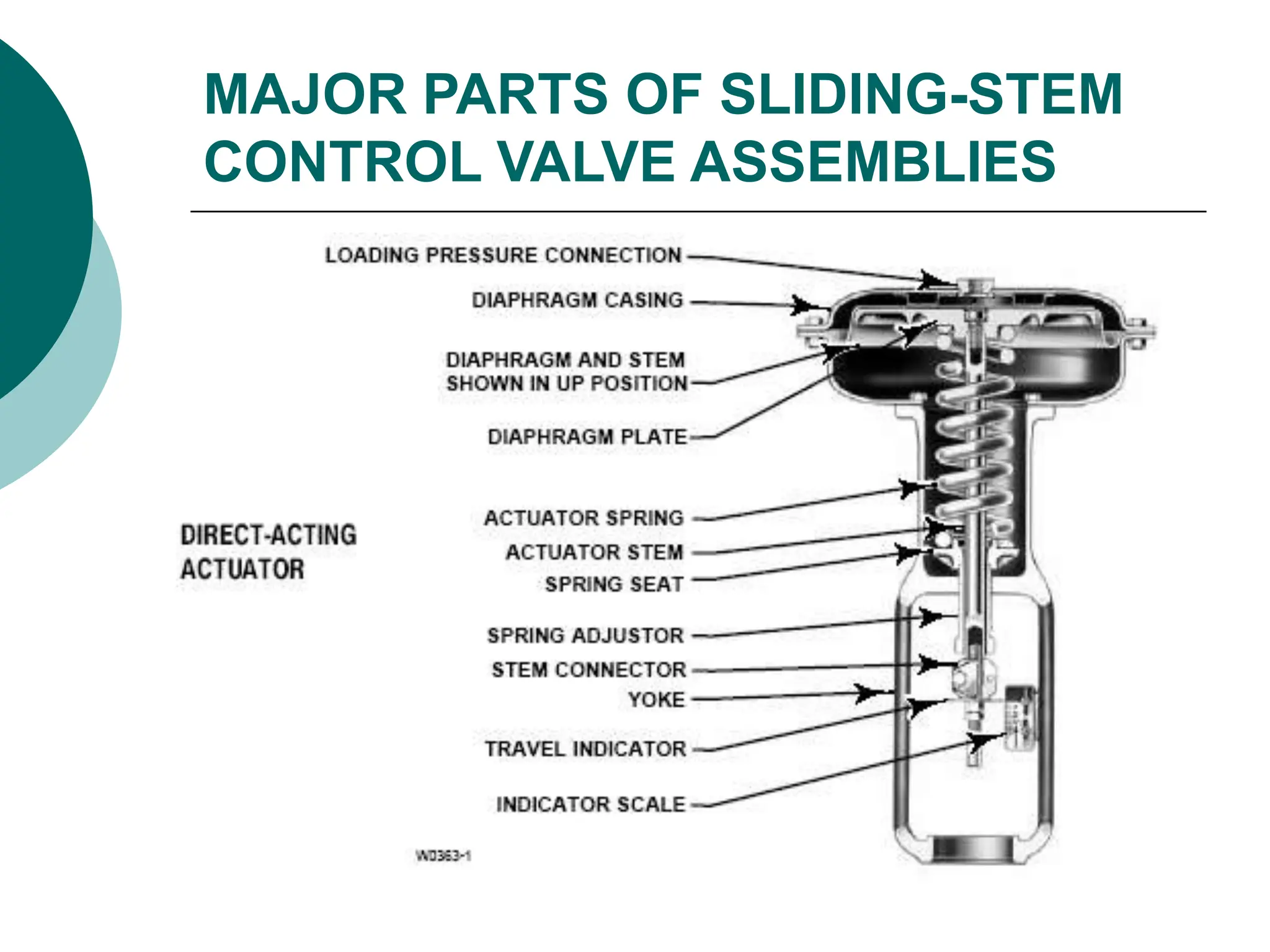

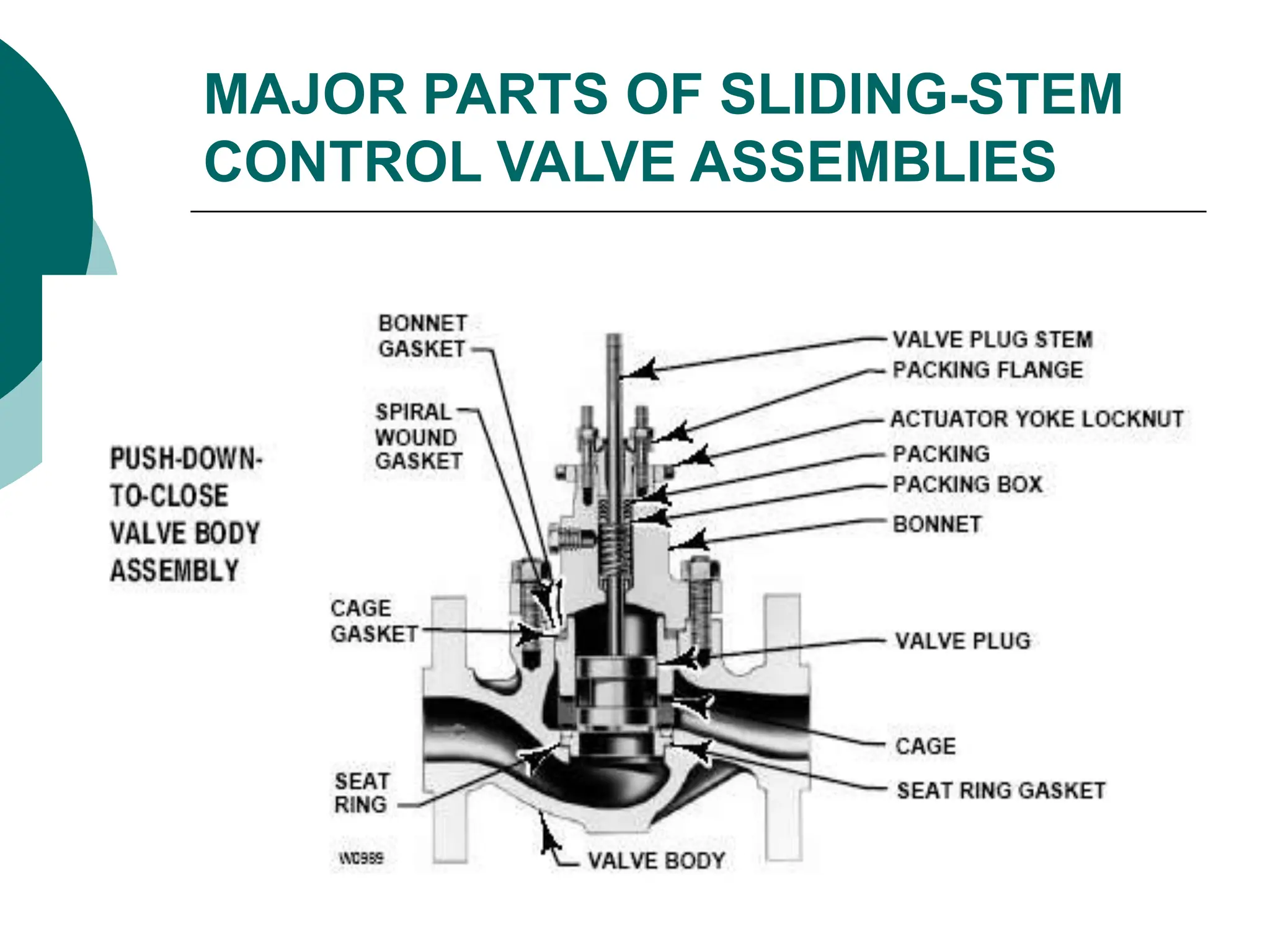

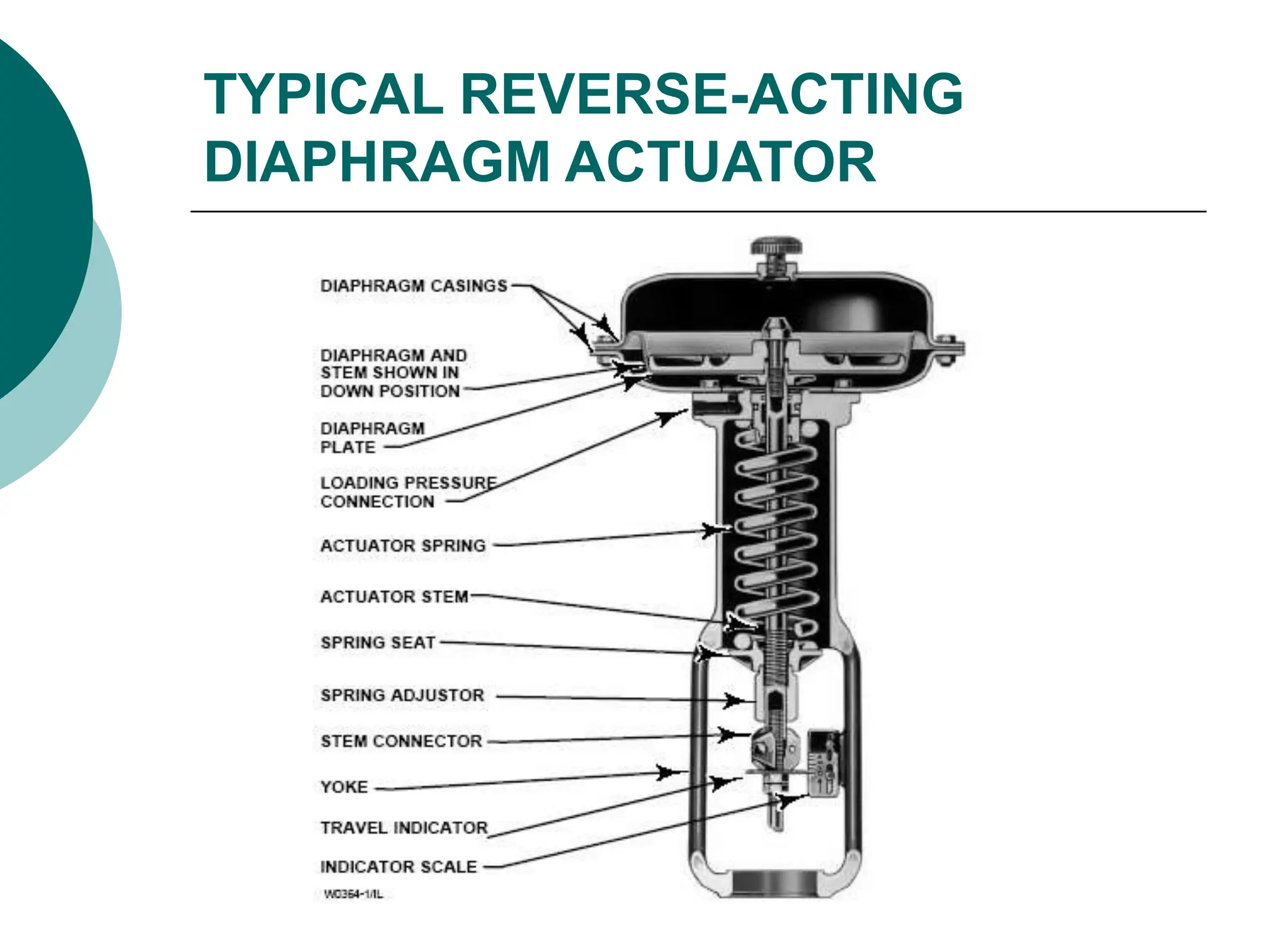

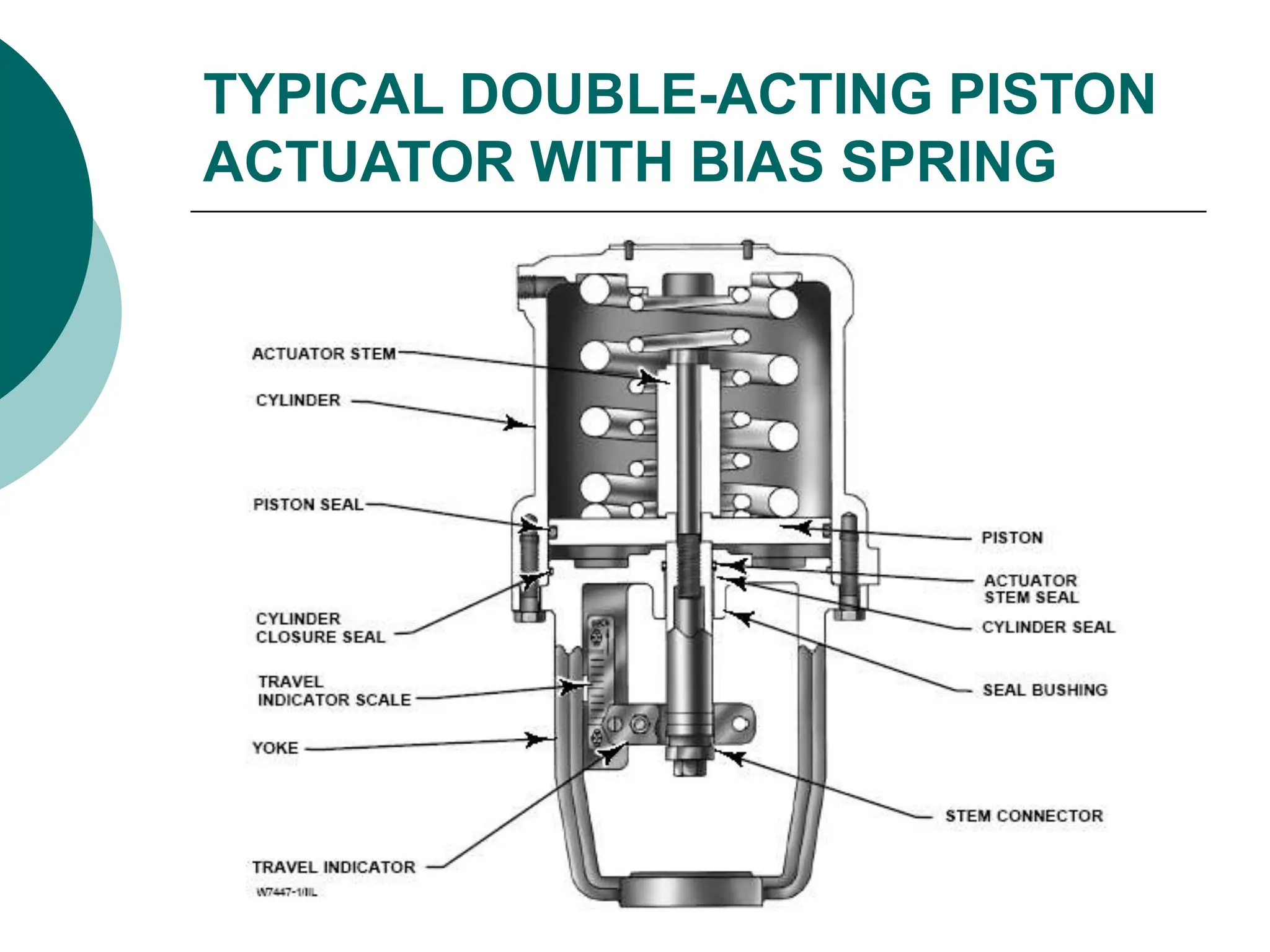

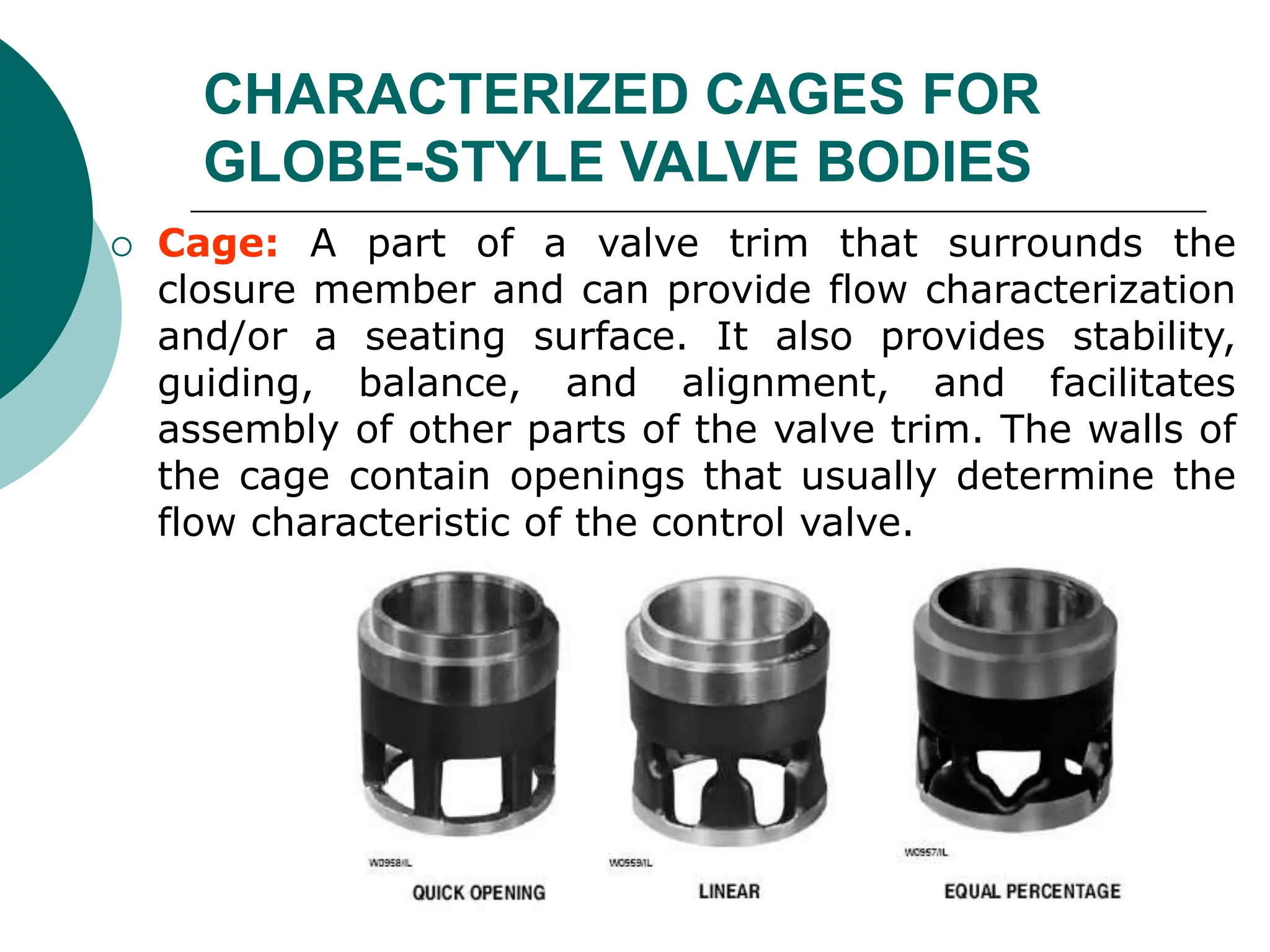

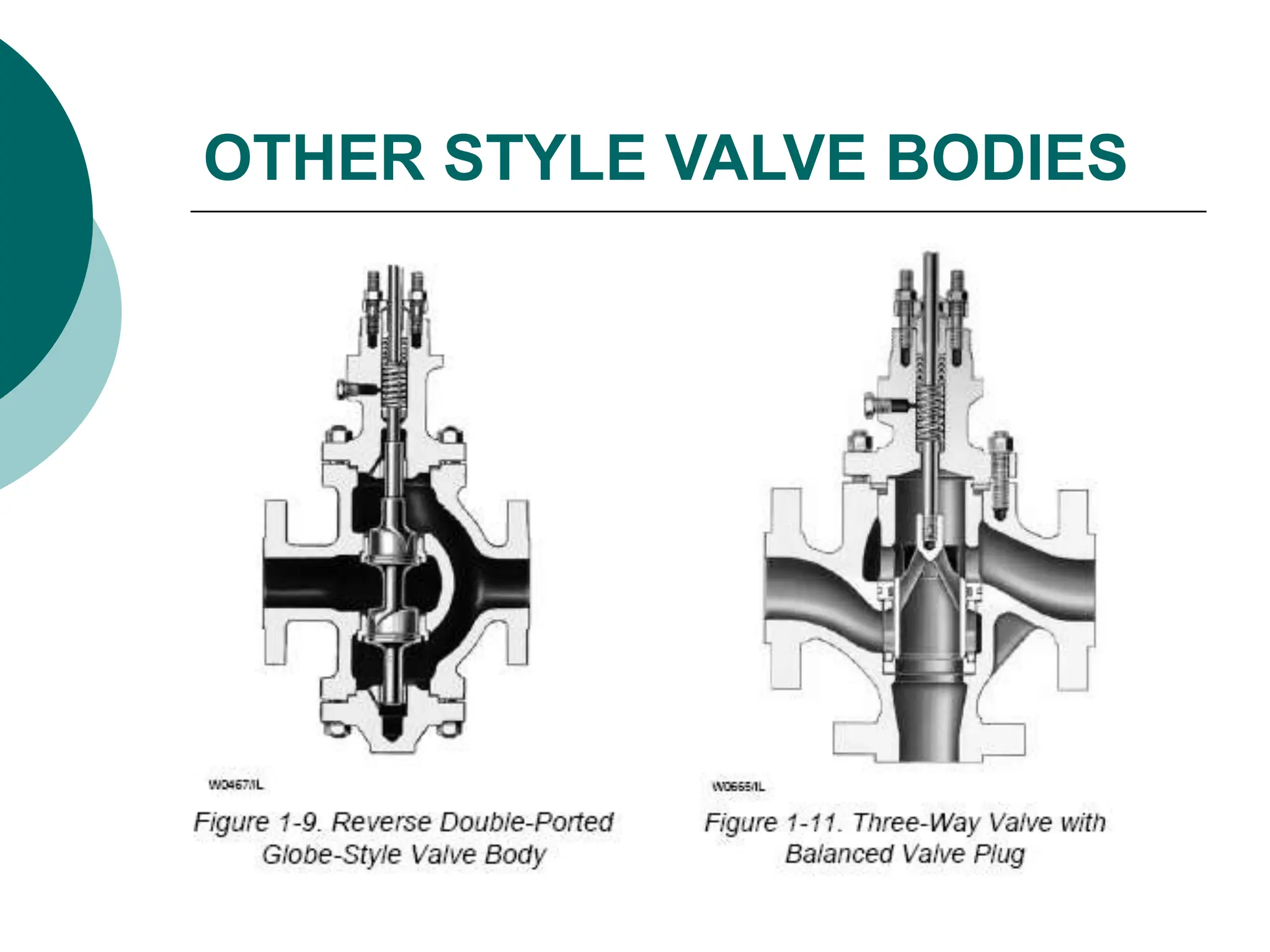

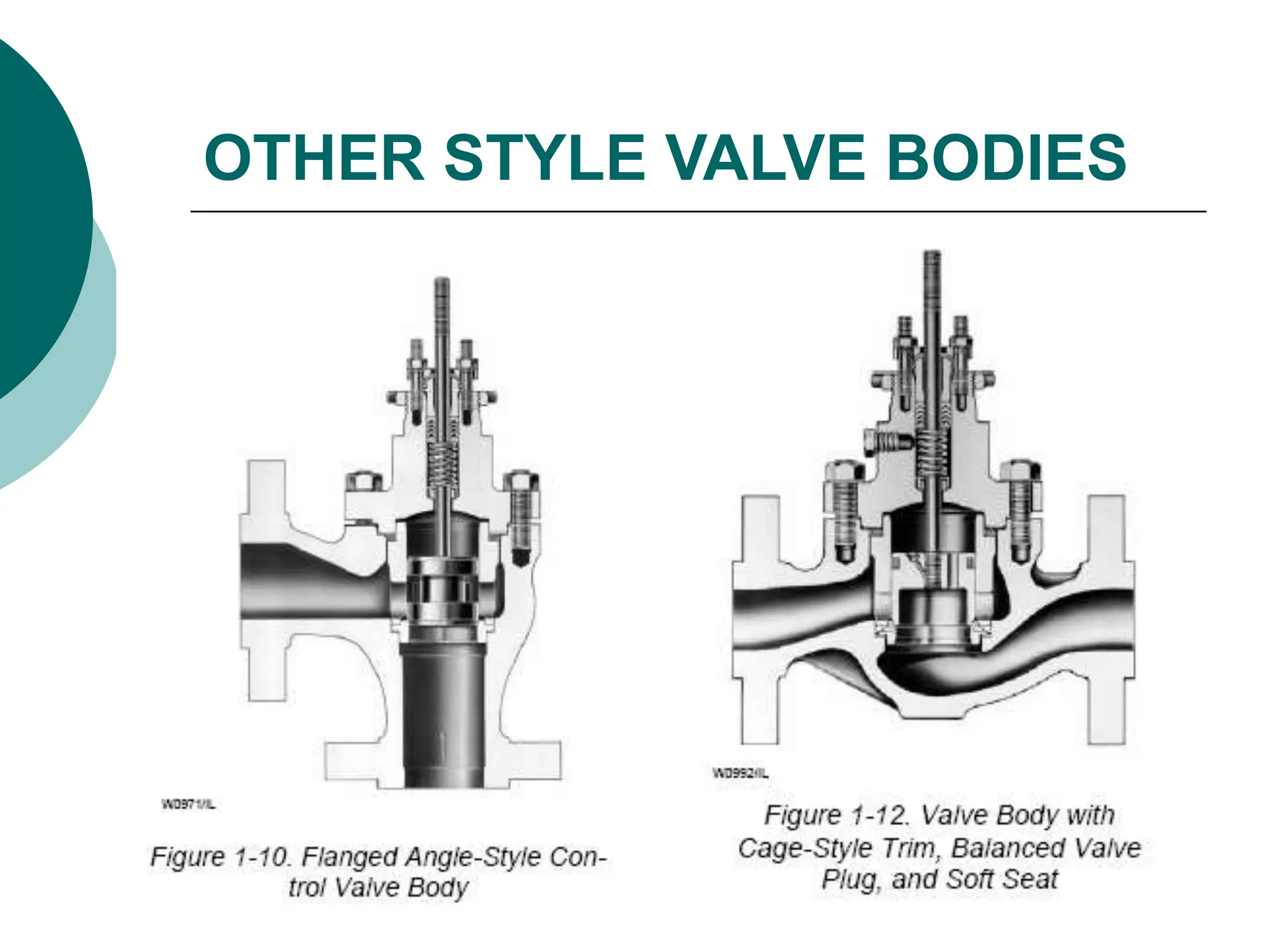

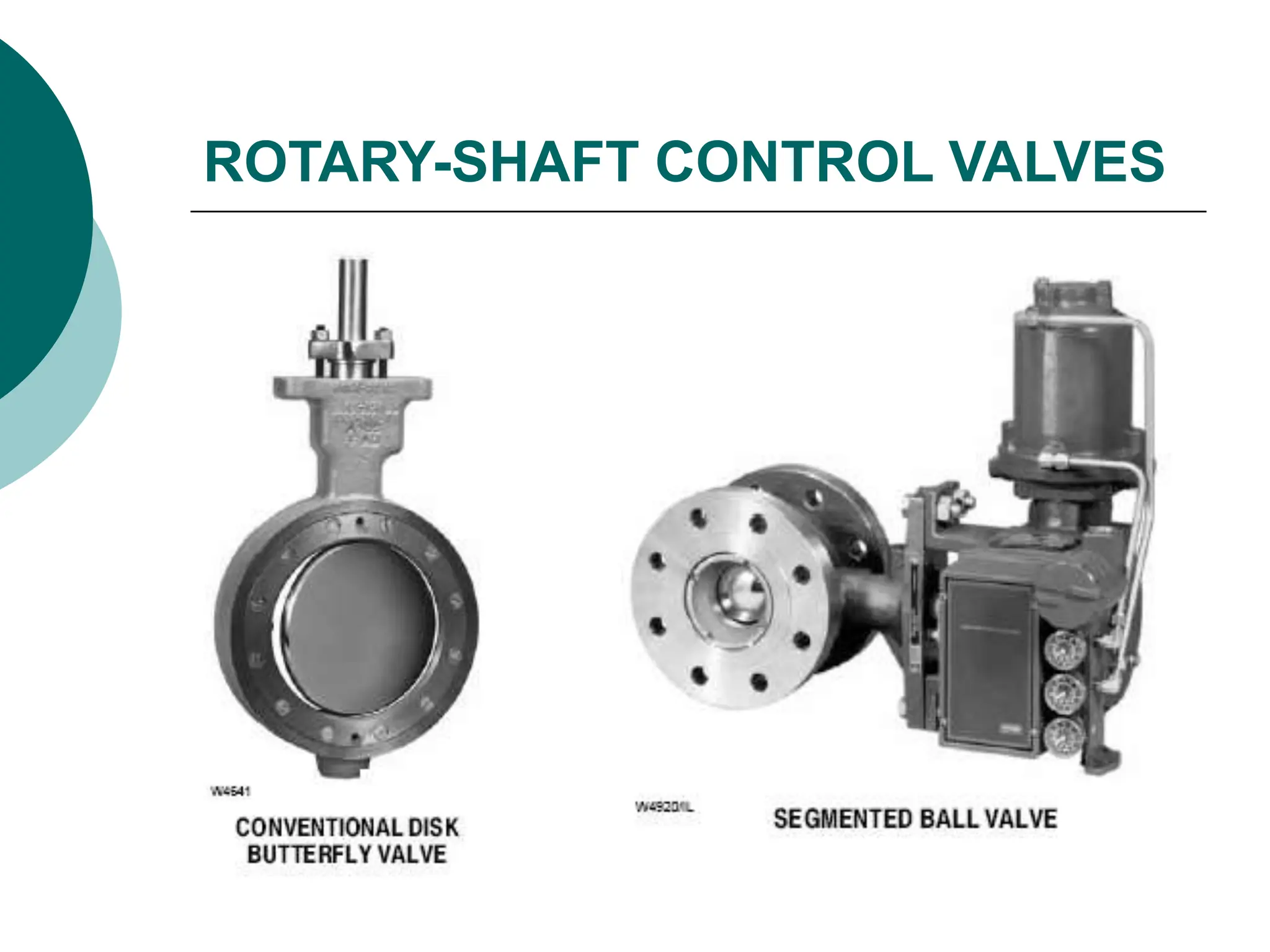

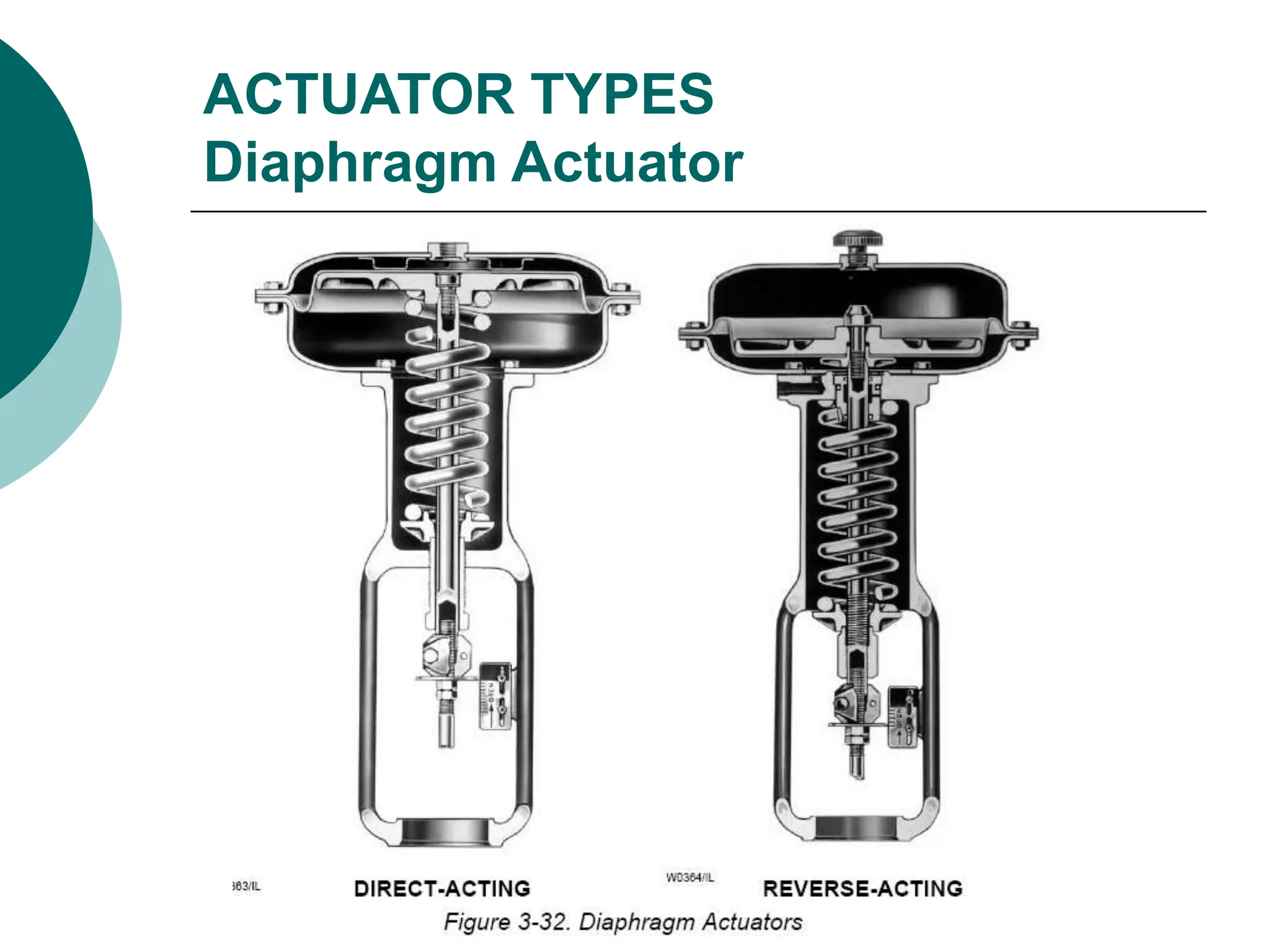

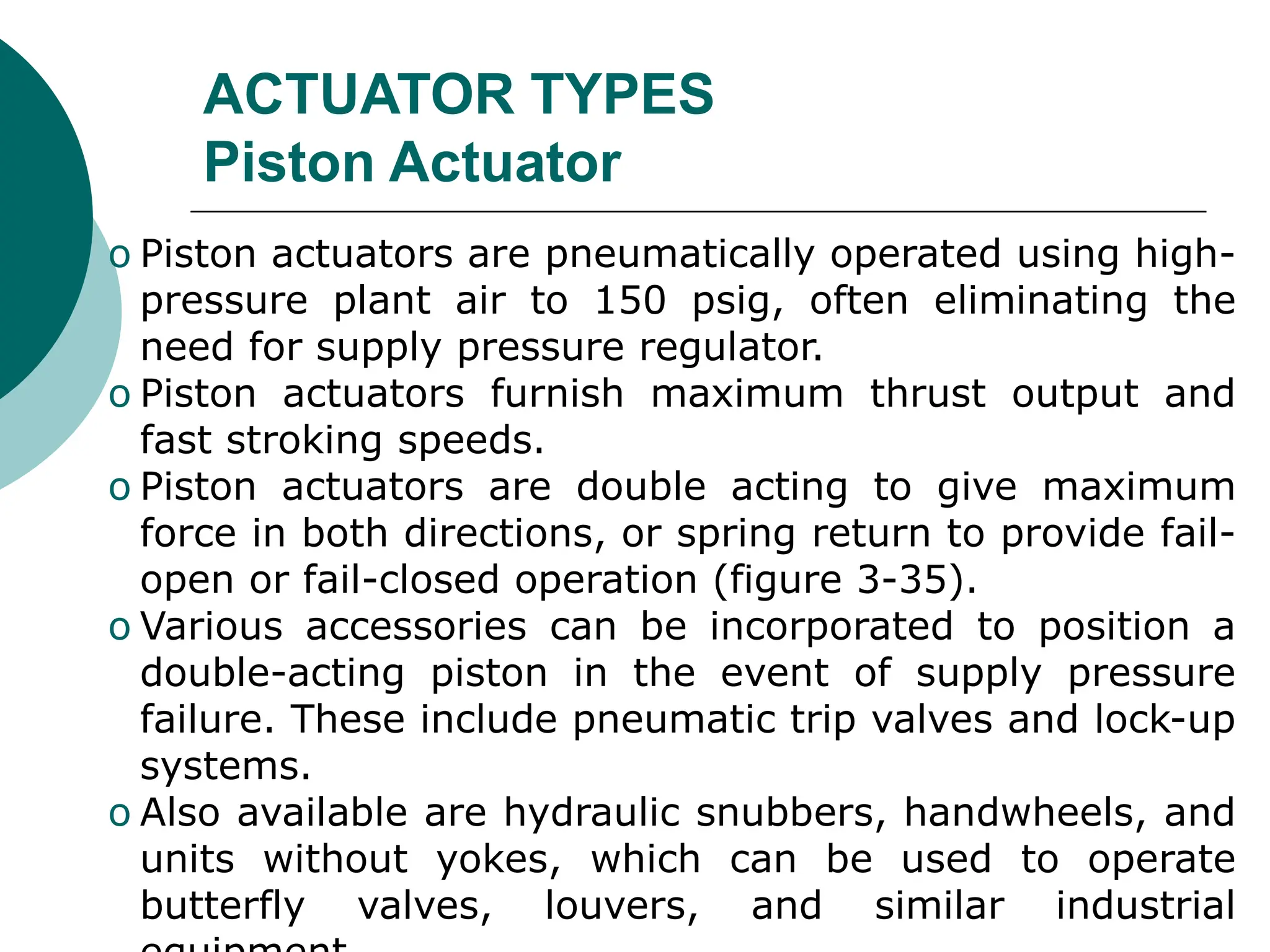

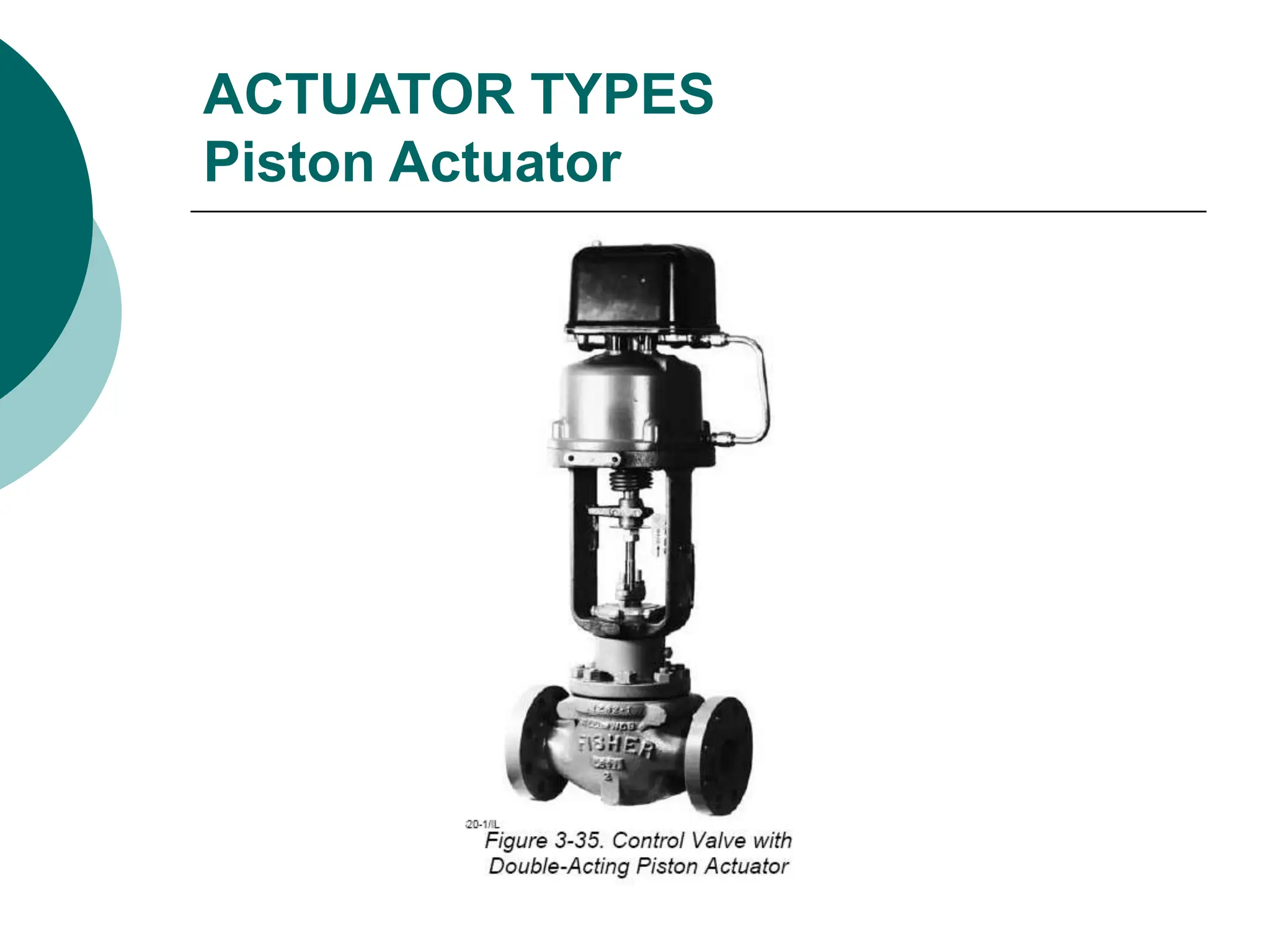

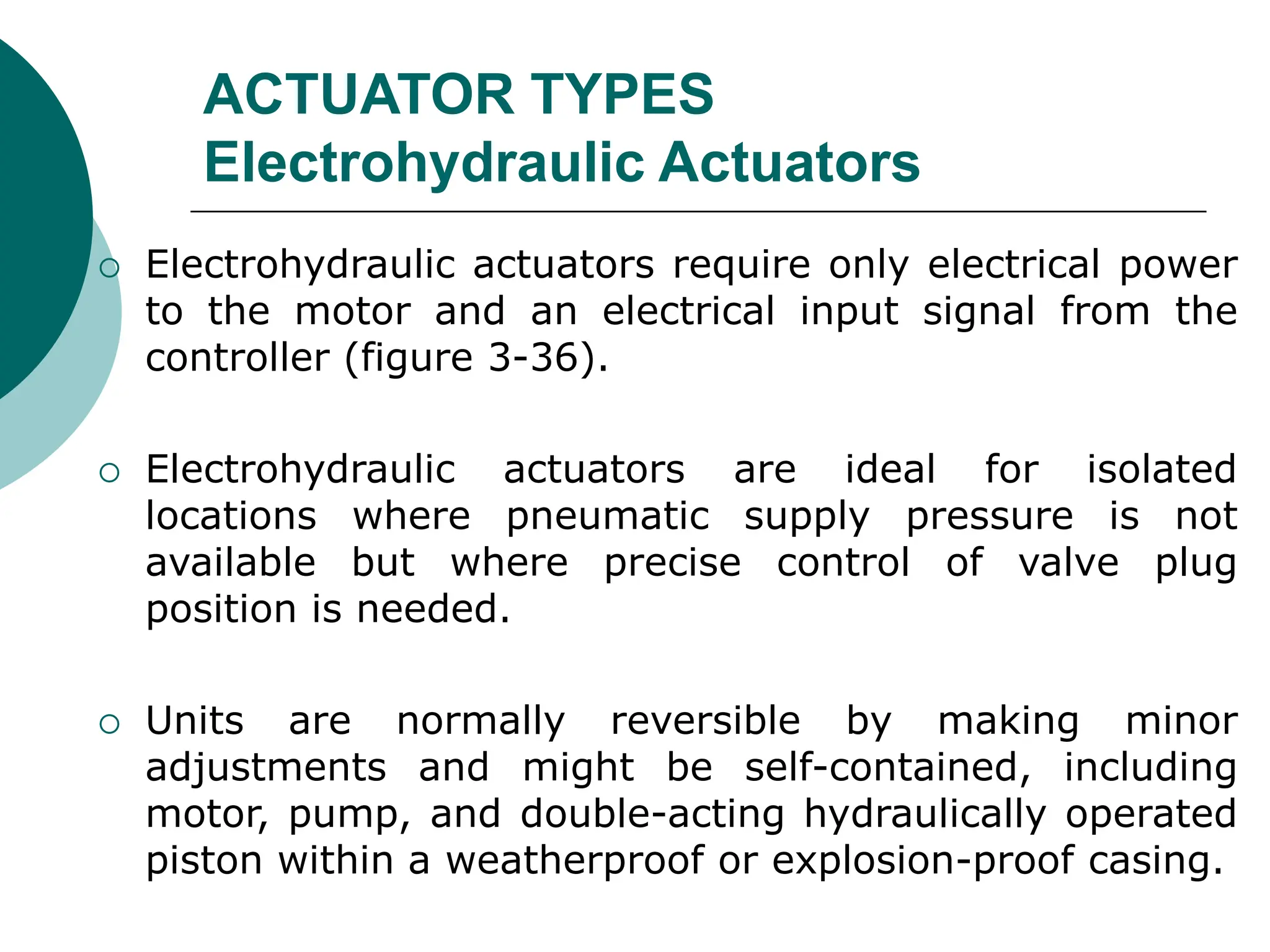

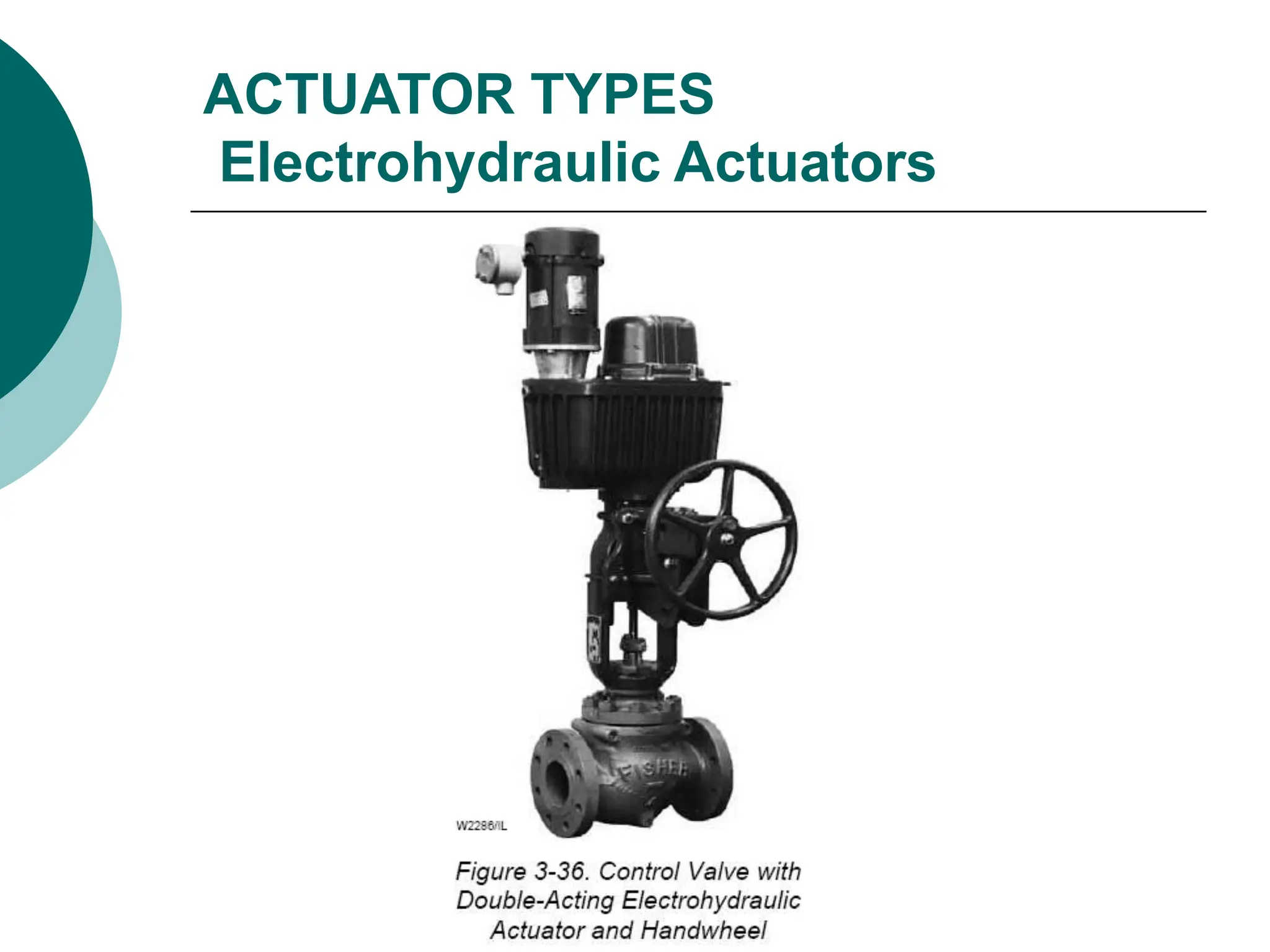

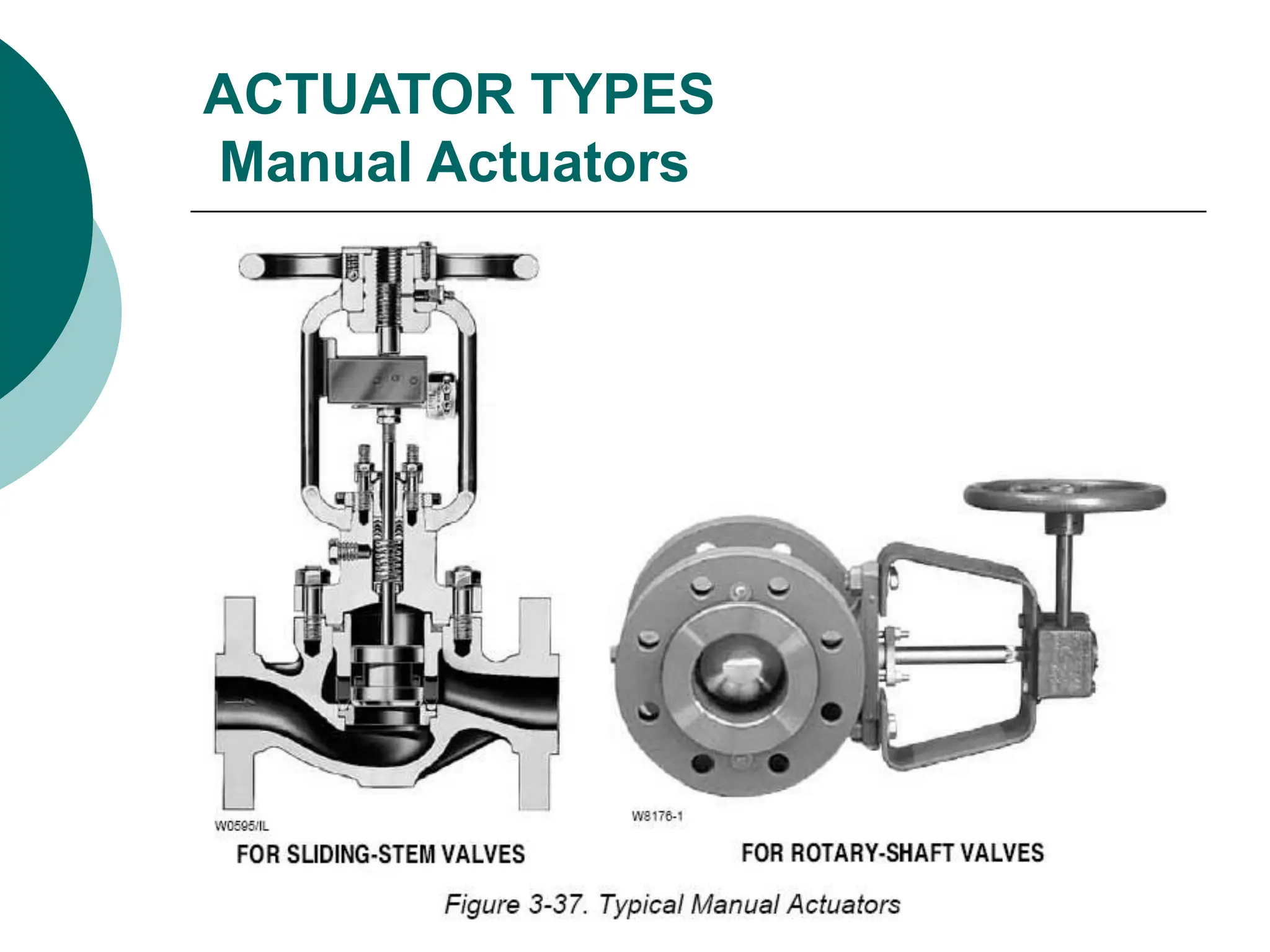

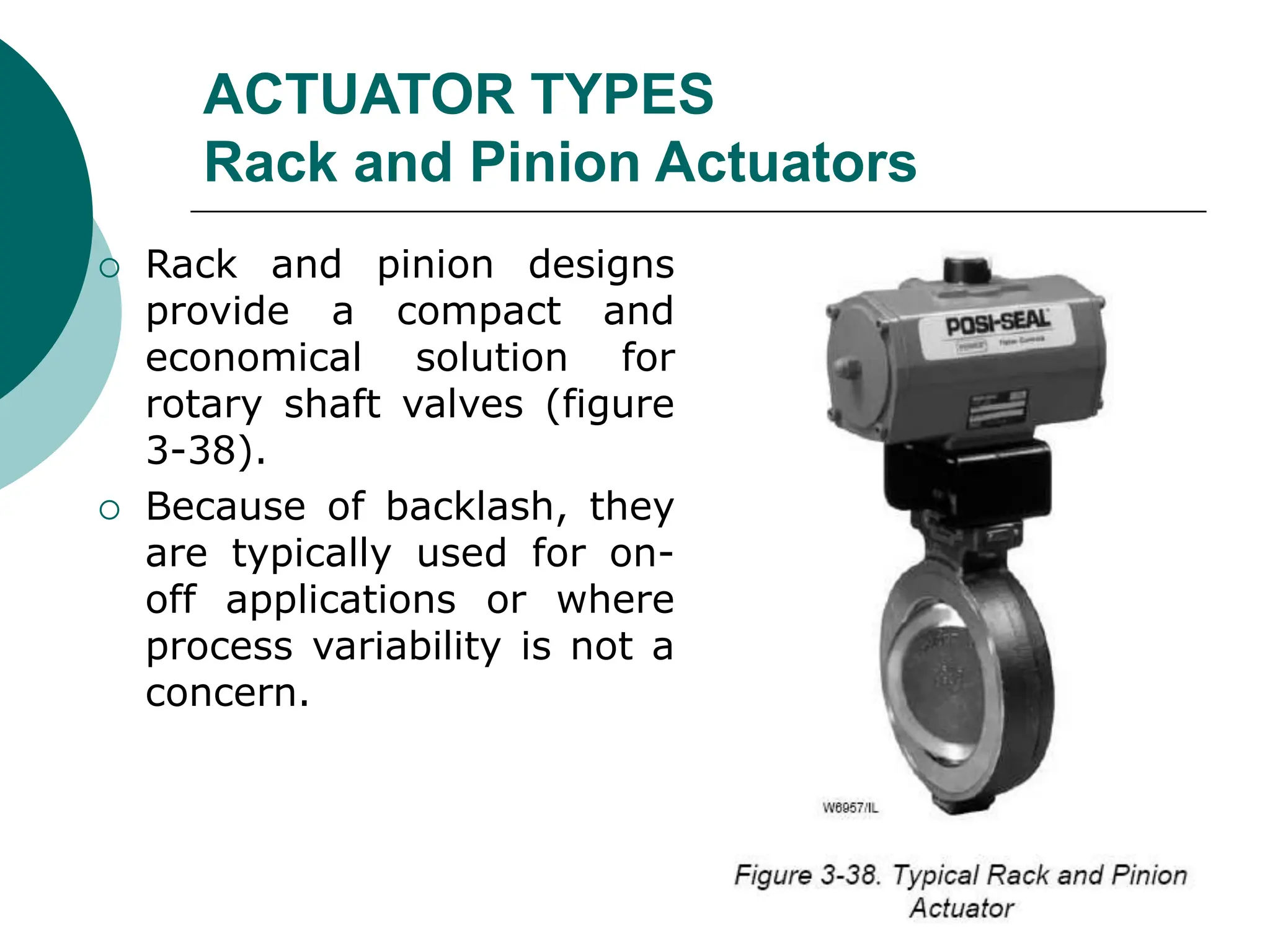

The document provides an overview of control valves in process plants, describing their role in maintaining important process variables such as pressure and flow. It details the components of control valves, types of actuators (pneumatic, electric, hydraulic, manual), and terminology related to their function. Additionally, it discusses the significance of sensors, positioners, and other accessories in optimizing valve performance.