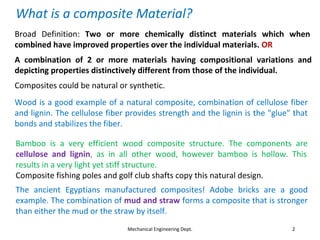

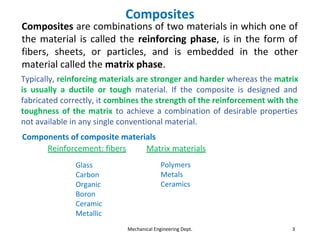

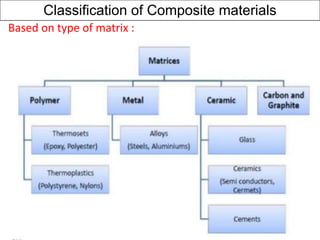

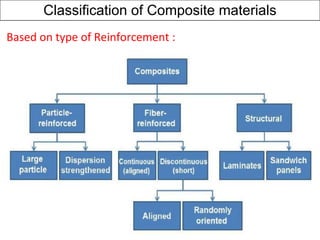

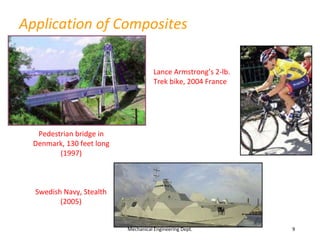

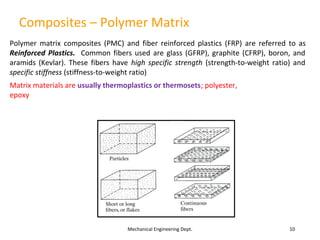

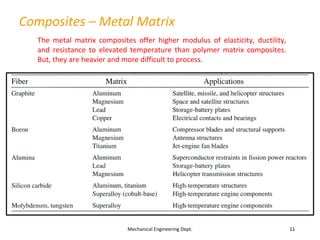

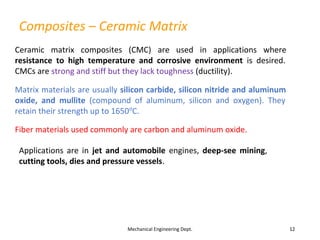

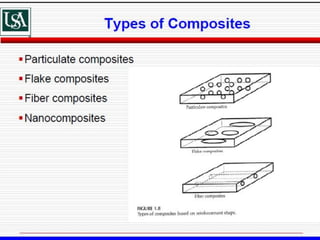

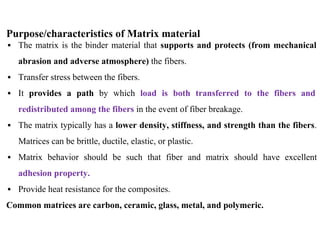

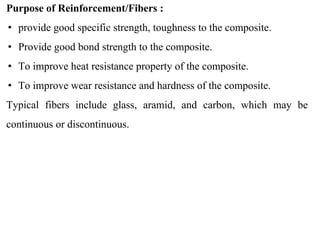

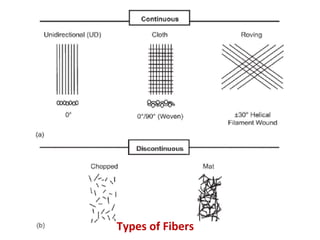

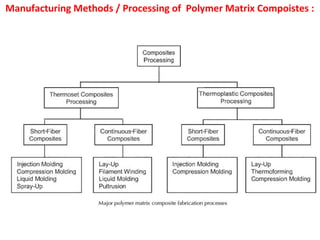

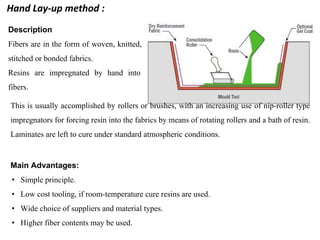

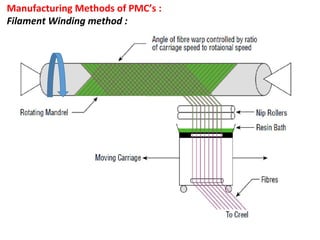

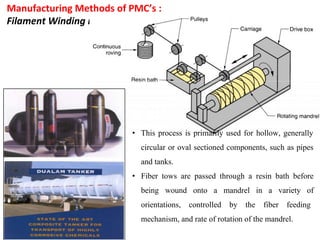

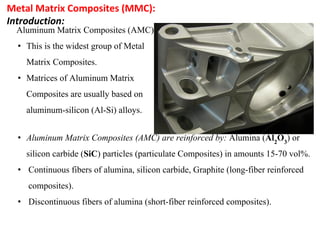

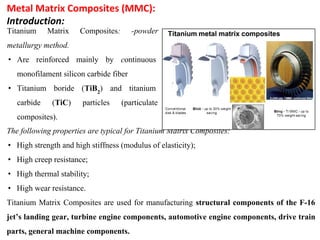

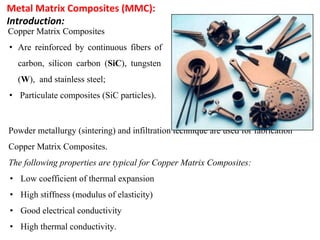

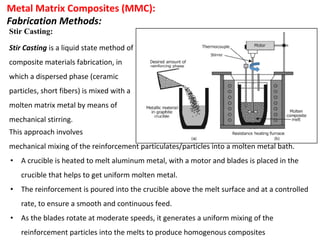

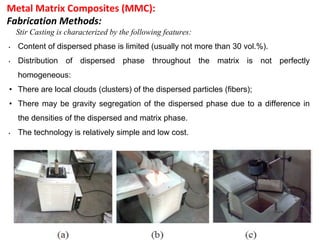

The documents discuss composite materials, which are combinations of two or more materials that have improved properties over the individual components. Composite materials consist of a reinforcement and a matrix. Reinforcements provide strength and stiffness, while the matrix binds the reinforcements together and protects them. Common reinforcement materials include fibers of glass, carbon, and aramid. Matrix materials include polymers, metals, and ceramics. The documents describe different types of composites based on the matrix, such as polymer matrix composites, metal matrix composites, and ceramic matrix composites. Manufacturing methods for polymer matrix composites like hand lay-up, filament winding, and pultrusion are also summarized.

![Mechanical Engineering Dept. 1

• Introduction to composite materials: Definition,

classification of composites based matrix materials &

reinforcements, manufacturing of fibrous composites,

laminated composites, particulate composites (Hand

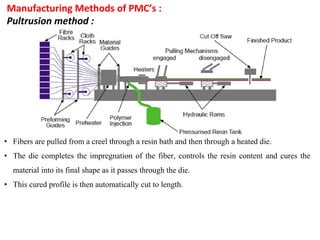

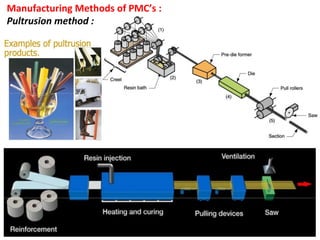

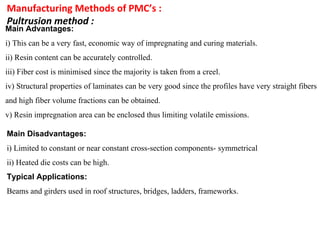

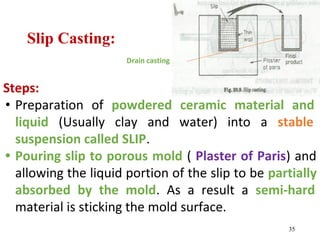

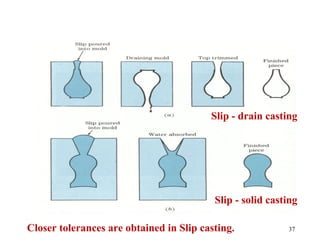

lay-up, Filament winding, Pultrusion, Slip casting and

Stir casting), advantages and application of

composites. [06]](https://image.slidesharecdn.com/compositematerials-240314052817-e402a3a3/75/Composite-materials-pdf-1-2048.jpg)