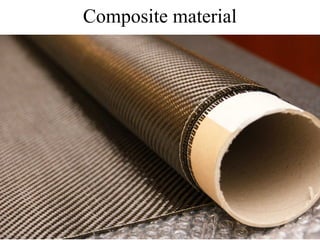

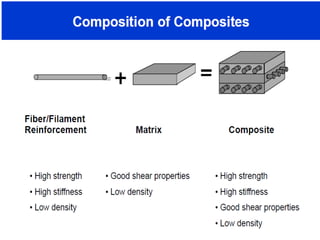

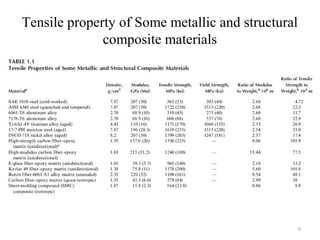

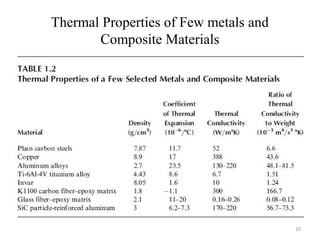

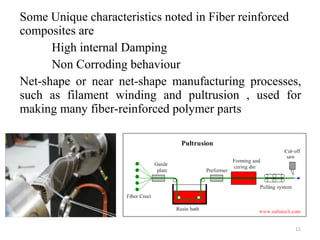

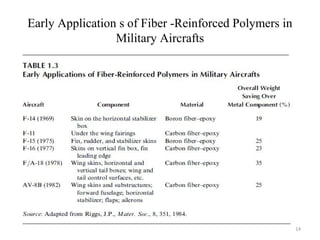

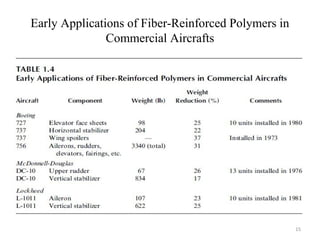

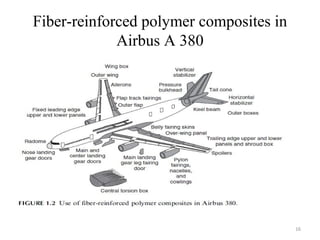

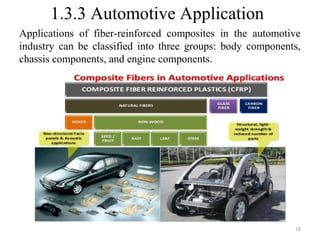

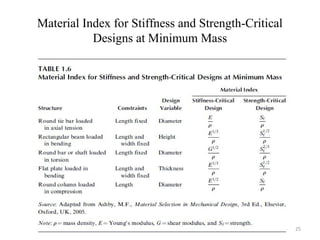

This document provides an introduction to fiber-reinforced composites. It discusses the history of composites beginning in the 1940s when they were used to create lightweight materials for military vehicles. It defines composites as materials made from two or more constituent materials that produce properties different from the individual components. The document outlines the characteristics of fiber-reinforced composites and provides examples of their applications in aircraft, space vehicles, automobiles, sporting goods, marine vessels, and infrastructure. It also discusses the material selection process for composites.