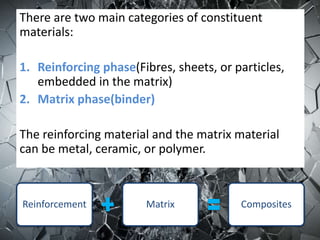

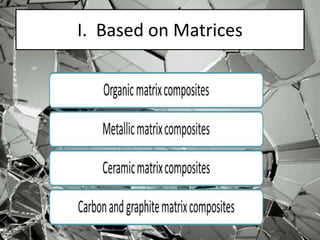

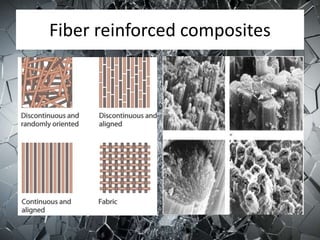

The document summarizes composites and their classification. It discusses that composites are made of two or more materials to produce new properties. Composites are classified based on the matrix and reinforcement geometry. The main matrix types are polymer, metal, ceramic. Reinforcements include fibers, sheets and particles. Fiber reinforced composites are widely used. Applications of composites include aerospace, automotive, construction, medical and more due to their high strength and stiffness but low density.