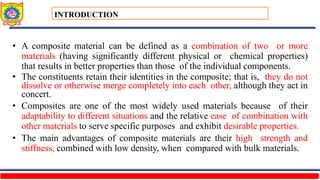

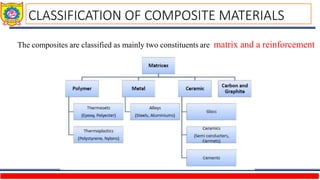

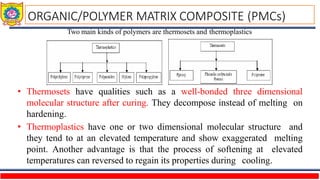

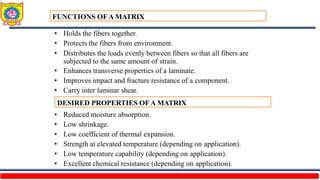

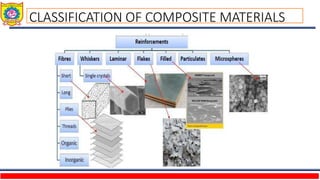

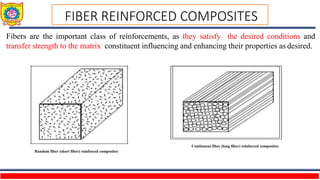

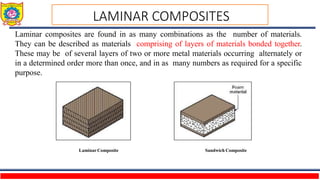

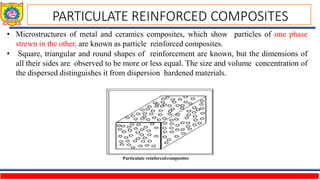

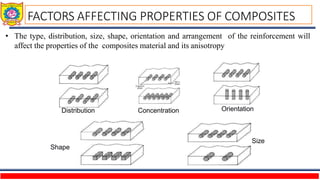

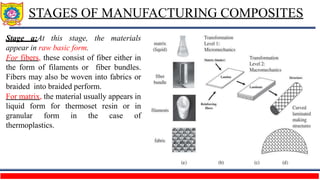

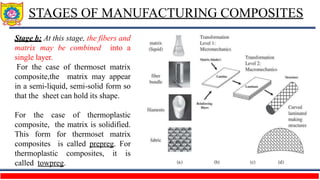

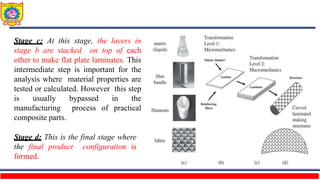

This document provides information on composite materials, including definitions, classifications, properties, advantages, limitations, and manufacturing processes. It defines a composite as a combination of two or more materials that results in improved properties over the individual components. Composites are classified based on their matrix material, such as polymer matrix composites, metal matrix composites, ceramic matrix composites, and carbon/carbon composites. The document discusses the various types of reinforcements and fillers used in composites, as well as the functions of the matrix and factors affecting composite properties. It also outlines the advantages of composites over metallic materials, some limitations, and applications in engineering. Finally, the stages of the manufacturing process for composites are briefly described.