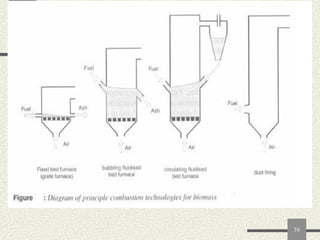

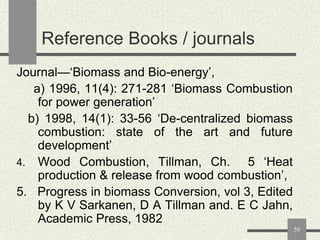

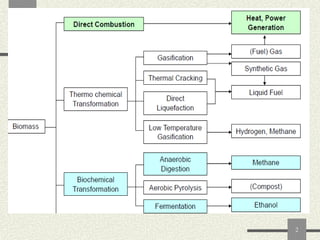

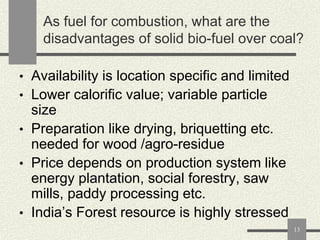

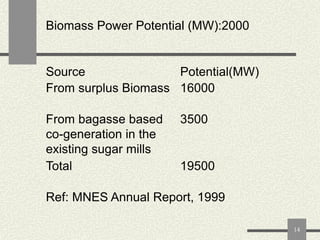

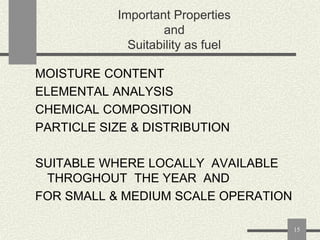

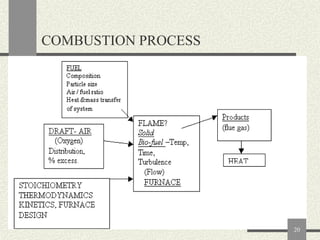

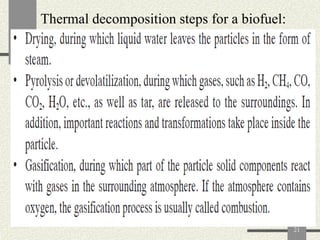

The document discusses solid biofuels and their role in energy production, particularly in rural areas, emphasizing biomass's potential to reduce dependence on fossil fuels. It covers the characteristics, preparation, and applications of biofuels, while also addressing the advantages and disadvantages of using solid biofuels compared to coal. Additionally, various combustion processes and technologies for biomass energy generation are detailed, along with the challenges associated with transport and efficiency.

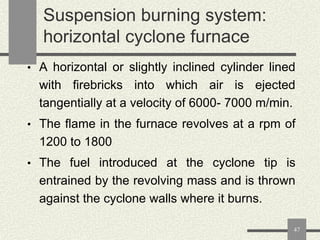

![Give examples of solid bio-fuels

WOOD [Forestry / agro-forestry based]

BAGASSE [Agro - industry residue]

RICE HUSK [Crop residue]

NEEM ETC.- [Multi-purpose trees]

PROSOPIS ETC.- [Energy crops]

8](https://image.slidesharecdn.com/combustionofsolidbiofuel-140203010508-phpapp02/85/Combustion-of-solid-biofuel-8-320.jpg)

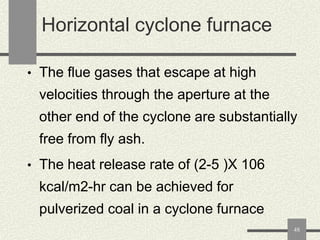

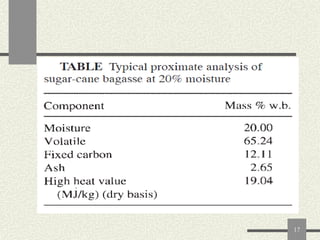

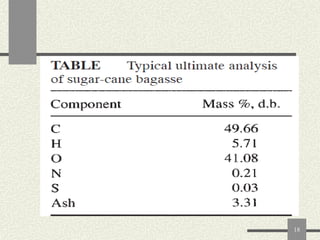

![Proximate and Ultimate Analysis,

and HHV

Proximate Analysis: (1) Moisture,

(2) Volatile,

(3) Fixed carbon and

(4) Ash. [Wt %]

Ultimate Analysis : C, H, O, N, S. [Wt %]

Higher Heating Value, MJ/Kg

16](https://image.slidesharecdn.com/combustionofsolidbiofuel-140203010508-phpapp02/85/Combustion-of-solid-biofuel-16-320.jpg)

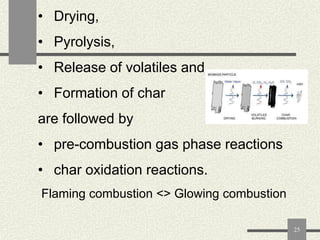

![Providing the Draft

P required to make the air flow through the

fuel bed and to the flue gas discharge height

is called draft of air in a furnace and is

expressed in millimeters of water.

Natural: by means of a chimney

Artificial: The fan is used to suck the gases

away from the furnace [induced draft], or to

force the air required [forced draft] through

the grate.

19](https://image.slidesharecdn.com/combustionofsolidbiofuel-140203010508-phpapp02/85/Combustion-of-solid-biofuel-19-320.jpg)

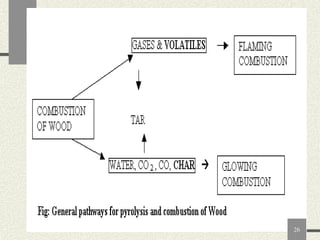

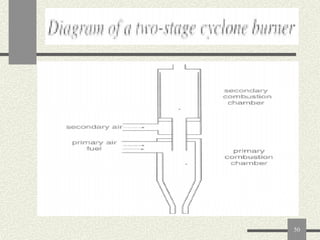

![COMBUSTION REACTIONS

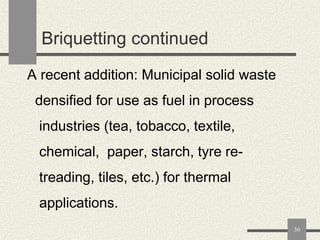

C6n[H2O]5n = 6nC + 5nH2O

Biomass

C + O2 + 3.79N2 = 3.79N2 +CO2

EXOTHERMIC, 395400 KJ / KG ATOM

OF CARBON

22](https://image.slidesharecdn.com/combustionofsolidbiofuel-140203010508-phpapp02/85/Combustion-of-solid-biofuel-22-320.jpg)