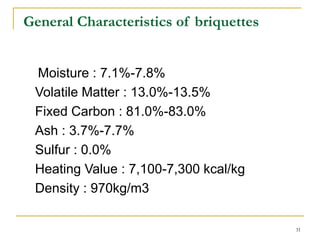

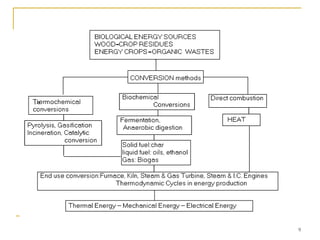

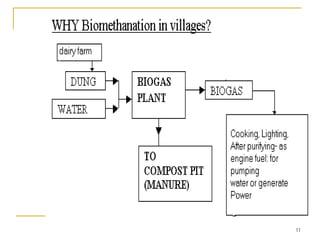

This document provides an overview of biomass conversion methods for energy production in India. It discusses various biomass feedstocks such as agricultural crops, residues, and waste streams. Common agricultural crops used are sugarcane, corn, and sweet sorghum. Briquetting and combustion are described as methods to convert biomass into solid and gaseous fuels. Rural communities have traditionally used biomass for cooking and heating. The objectives of new programs are to make biomass a sustainable and modern energy source. Briquetting techniques from an Indian research center are summarized, including carbonizing biomass in a furnace, using a starch binder, and forming uniform briquettes with a density of around 1,000 kg/

![INTRODUCTION

TO

ENERGY FROM BIOMASS PROCESSING

FOR INDIA

BIOMASS CONVERSION METHODS

BRIQUETTING

COMBUSTION OF SOLID BIOMASS

BIOMETHANATION [Biogas]](https://image.slidesharecdn.com/biomass-energyhasfuture-140109062609-phpapp01/85/Biomass-energy-in-India-1-320.jpg)

![MCRC’s method of charcoal briquetting [continued]

ii. Carbonizing the biomass

• The biomass is tightly packed into the

inner drum and fired for 45minutes to 1hr

(Depending upon the biomass) using

biomass.

• After firing, the carbonized biomass in the

inner drum has to collected and weighed. In

this method 30 % of carbonized char can be

obtained.

28](https://image.slidesharecdn.com/biomass-energyhasfuture-140109062609-phpapp01/85/Biomass-energy-in-India-28-320.jpg)