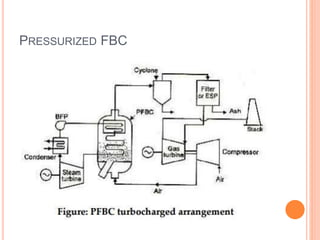

This document provides an overview of fluidized bed combustion (FBC), including its basic theory, design, and operational aspects in the steam generation industry. It discusses the benefits of FBC in increasing power generation efficiency while controlling emissions and contrasts it with traditional coal-fired power systems. The document also outlines different types of FBC, including atmospheric and pressurized fluidized bed combustion, and their respective advantages in terms of fuel flexibility, pollution control, and efficiency.