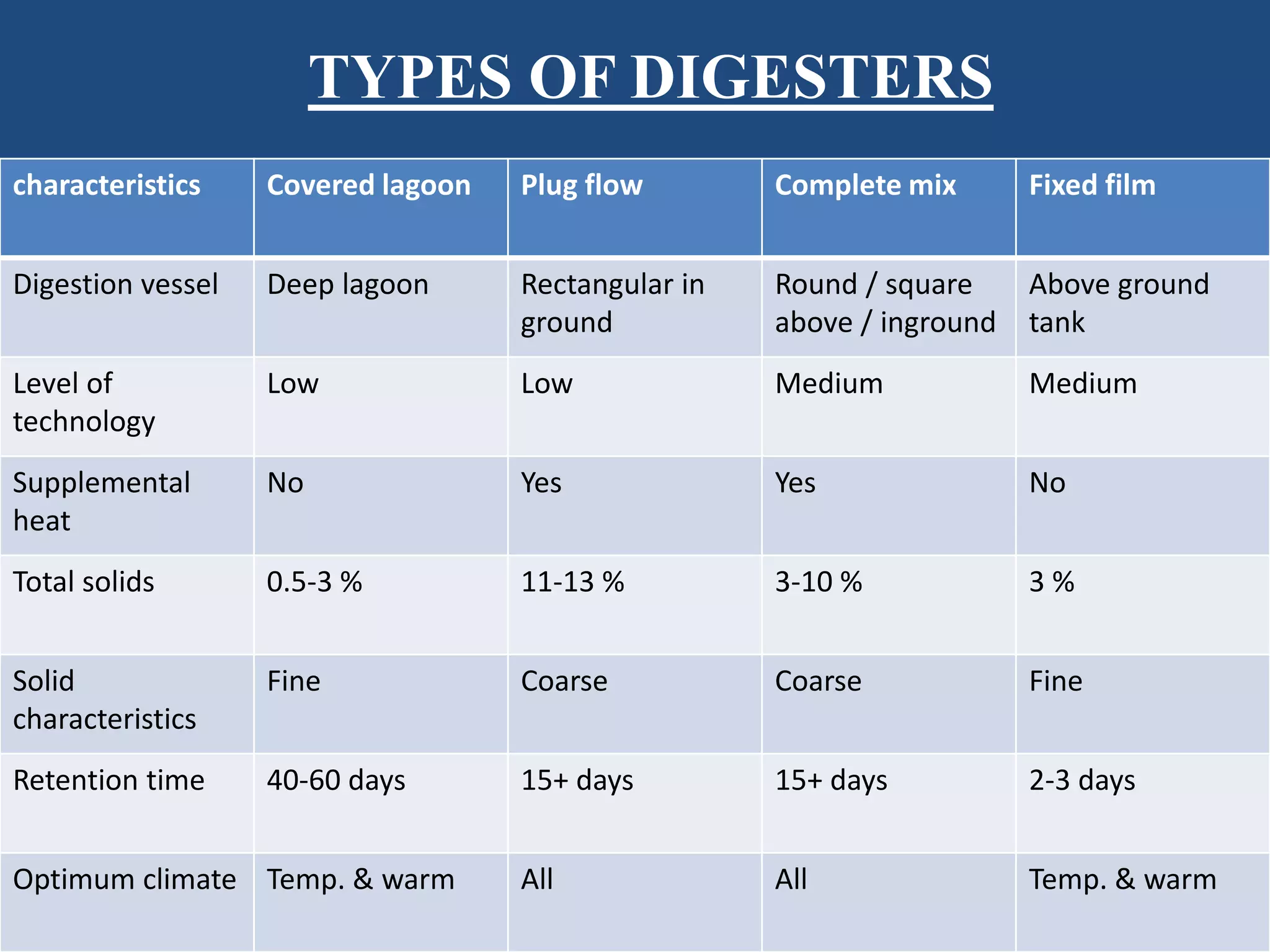

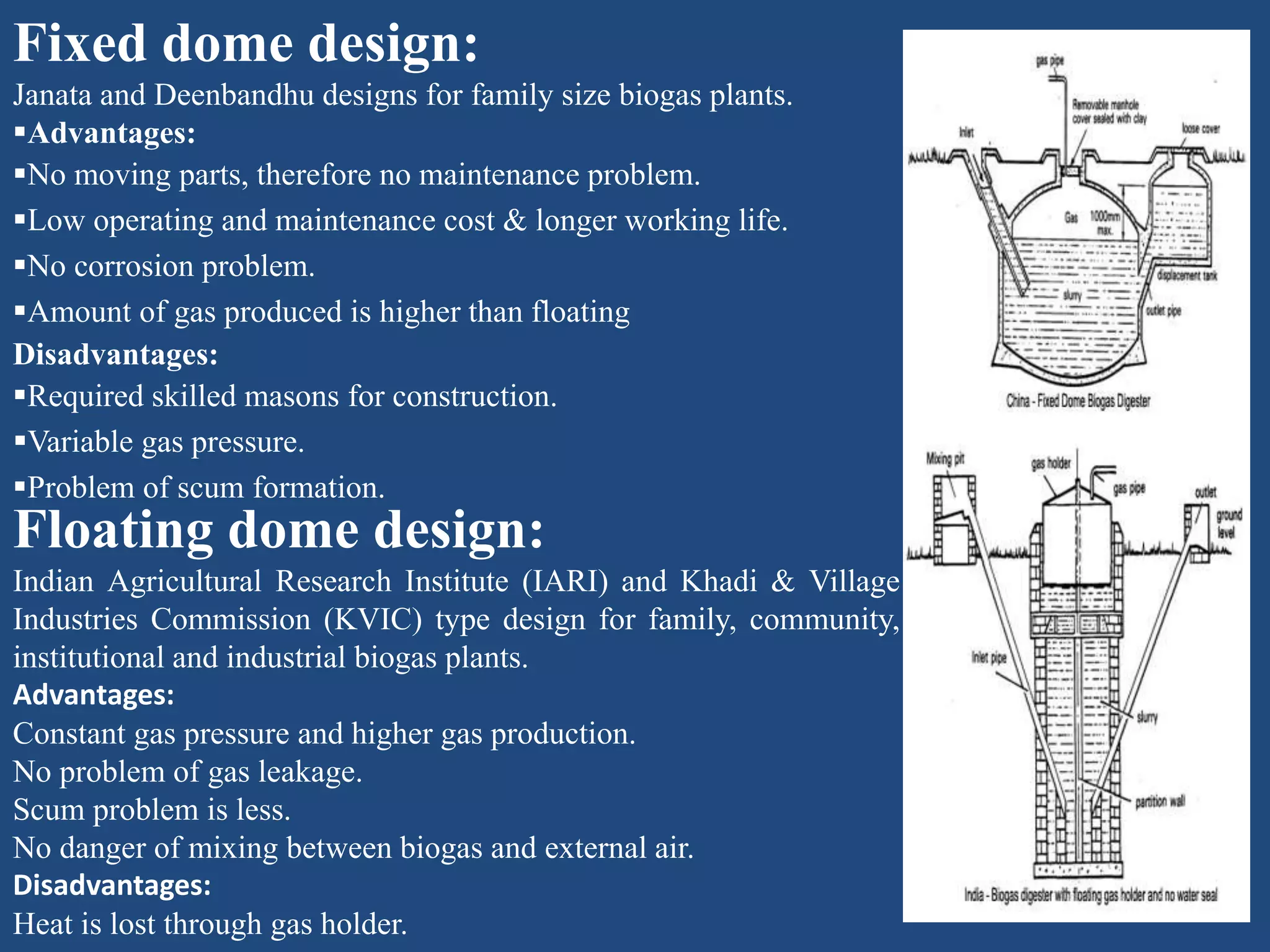

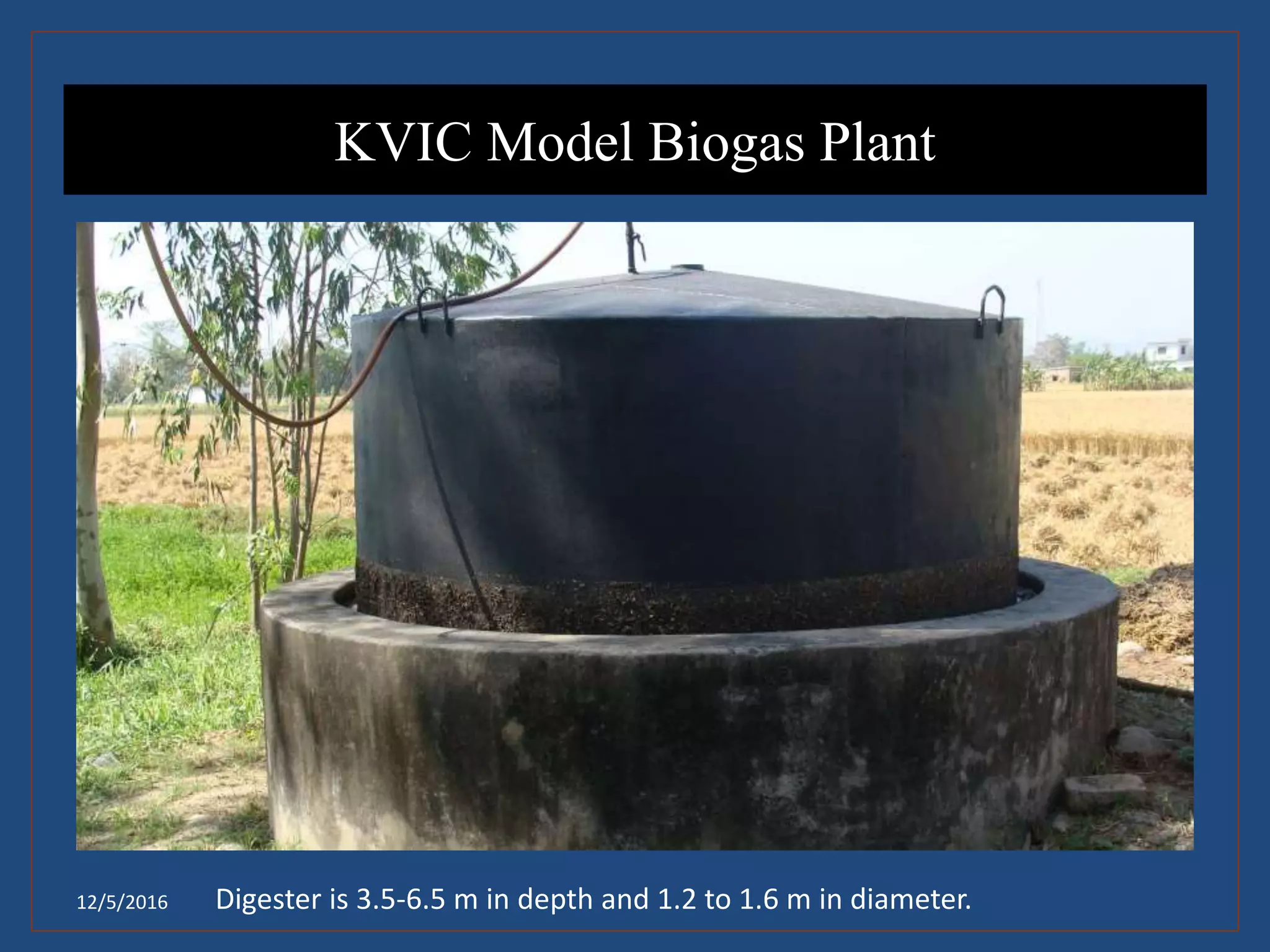

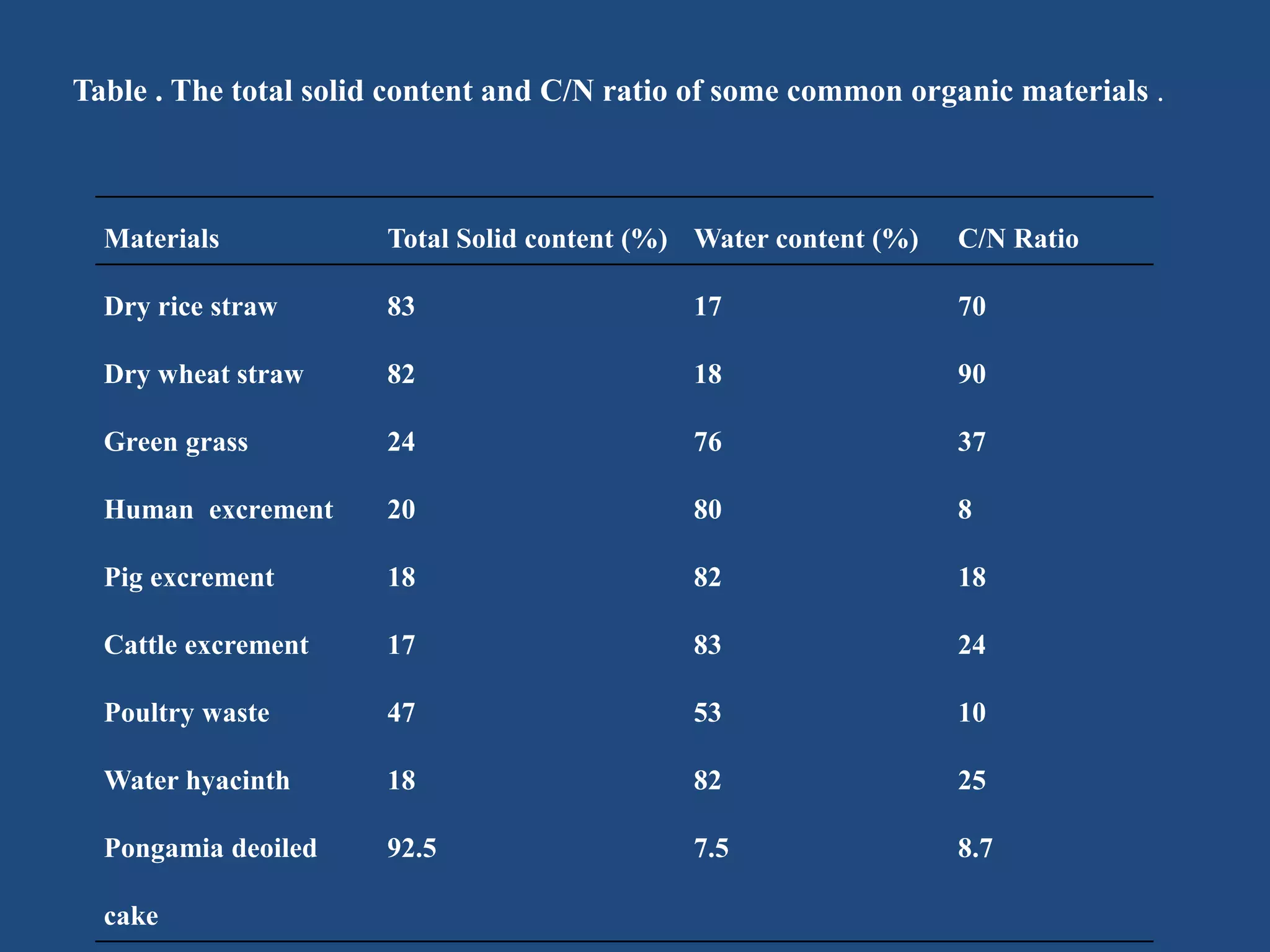

Biogas is produced through the anaerobic digestion of organic waste in an airtight digester. There are different types of digesters that vary in their design, technology level, retention time, and climate suitability. The main types are covered lagoon digesters, plug flow digesters, complete mix digesters, and fixed film digesters. Biogas is a renewable and environmentally friendly fuel that is around 55-65% methane and can be used as a replacement for firewood and fossil fuels.