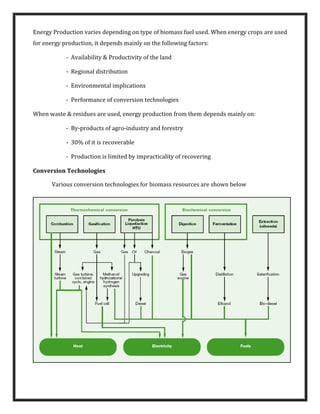

This document discusses biomass energy, which includes energy from plant and animal matter that can be converted into modern fuels, electricity, and heat. Biomass has advantages over other renewables in that it can be used in different forms like gas or electricity. Small, medium, and large-scale biomass options are described. Various biomass resources like woody, non-woody, processed waste and fuels are classified. Thermochemical and biochemical conversion technologies to generate electricity, heat and fuels from biomass are also outlined.