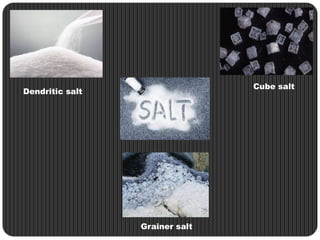

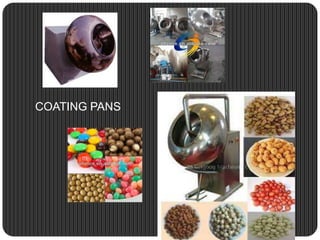

This document discusses coating methods used in the snack food industry. It begins by defining coating as applying a liquid or solid layer to a product using mechanical energy. Common coating methods for snacks include conveyor belts, tumble drums, coating pans, and enrobing. Conveyor belts coat one side of snacks while tumble drums coat both sides more evenly. Coating pans are used for sugary and chocolate coatings. Enrobing involves dipping, pouring, or spraying a liquid coating. Seasonings are important coatings and salt is most common, but other flavors like cheese and BBQ are also used. Powder coatings can be applied via gravity, air, or centrifugal force while liquid coatings and electro