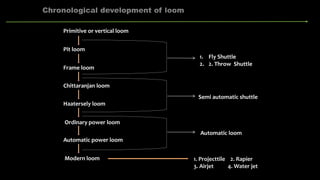

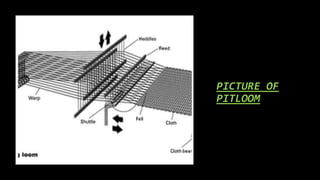

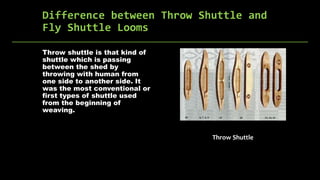

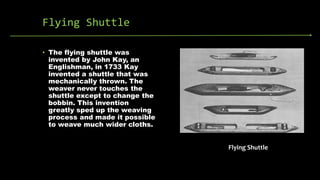

The document discusses different types of looms, focusing on the pit loom. It describes the pit loom as being invented in 1766 BC in Egypt, where the weaver would sit in a pit with their legs and use foot pedals to open the warp threads for the shuttle. The pit loom leaves the weaver's hands free to pass the shuttle across. It provides pictures and describes the basic structure of a pit loom, including components like the shuttle, shuttle box, warp beam, cloth roller, heddles, reed, and differences between throw shuttle and fly shuttle pit looms. Advantages are noted as producing texture and higher production than other early looms, while disadvantages include difficulty controlling many heddles and setting