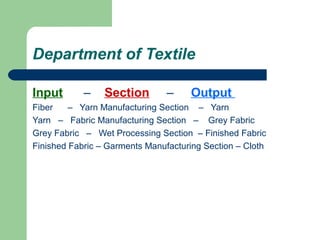

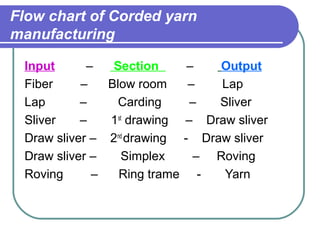

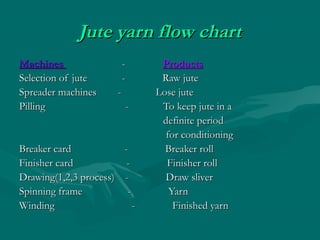

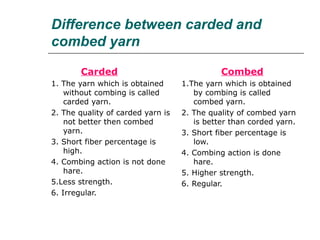

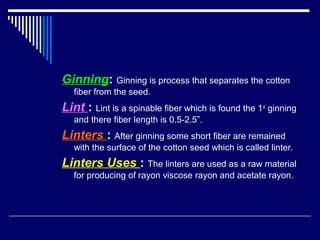

The document provides an overview of textile engineering, focusing on the processes involved in yarn manufacturing, including spinning and the differences between carded and combed yarn. It describes various spinning techniques, flow charts for the production of jute yarn, and the ginning process that separates cotton fibers from seeds. The document aims to highlight the stages of textile production and the quality distinctions between types of yarn.